Thin film super absorber with low cost and large area and preparation method of film

A large-area thin-film, super-absorbing technology, applied in metal material coating process, superimposed layer plating, layered products, etc., can solve problems such as being unsuitable for super-large area preparation, and achieve a simple, easy-to-implement method and broad commercial prospects. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

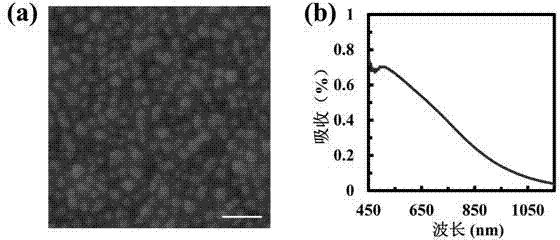

[0031] Example 1: Glass substrate / silver mirror / SiO 2 Dielectric layer / regular nanoparticles

[0032] (1) With the glass substrate as the substrate, a 100 nm thick flat Ag film is plated in the magnetron sputtering equipment, and 90 nm SiO is sputtered on it 2 membrane.

[0033] (2) In Ag / SiO 2 Continue to sputter a silver film with a nominal thickness of 6 nm on the film. Since the thickness is much smaller than the permeation threshold, the actual film layer does not form a continuous flat film, but random regular-shaped silver nano-islands.

[0034] (3) figure 2 (b) is the measured optical absorption spectrum, and the results show that the absorption peak of the absorber reaches more than 70%, and the absorption has a broad-spectrum property in the visible light band.

Embodiment 2

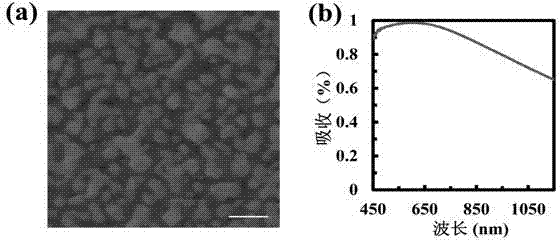

[0035] Example 2: Glass substrate / silver mirror / SiO 2 Dielectric layer / irregular nanoparticles

[0036] (1) With the glass substrate as the substrate, a 100 nm thick flat Ag film is plated in the magnetron sputtering equipment, and 90 nm SiO is sputtered on it 2 membrane.

[0037] (2) In Ag / SiO 2 Continue to sputter a silver film with a nominal thickness of 9 nm on the film. Since the thickness is slightly smaller than the permeation threshold, the actual film layer does not form a continuous flat film, but forms metal nanoparticles, and the air gap between the particles is much smaller than figure 2 structure shown in .

[0038] (3) image 3 (b) is the measured optical absorption spectrum. The results show that the three-layer structure achieves 100% optical absorption, and the ultrahigh absorption has ultra-broadband characteristics in the visible and near-infrared bands.

Embodiment 3

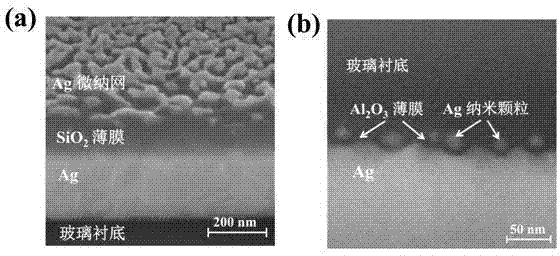

[0039] Embodiment 3: glass substrate / silver mirror / SiO 2 Dielectric layer / silver nanomesh

[0040] (1) With the glass substrate as the substrate, a 100 nm thick flat Ag film is plated in the magnetron sputtering equipment, and 90 nm SiO is continuously sputtered on it 2 membrane.

[0041] (2) In Ag / SiO 2 Continue to sputter a silver film with a nominal thickness of 12 nm on the film. Since the thickness is greater than the permeation threshold, although the actual film layer does not form a continuous flat film, the surface morphology formed is no longer discrete silver nano-islands, but interconnected. connected silver nanomesh, such as figure 1 (a) shown. The network structure combined with the underlying continuous metal film can be conveniently used as two electrodes of a photoelectric device.

[0042] (3) Figure 4 (a) is a photo taken of the sample under white light irradiation. The photo shows darker colors, while only faint blue light is reflected by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com