Thulium-holmium-codoped zirconium dioxide glass up-conversion luminescence material, and preparation method and application thereof

A technology of zirconia and luminescent materials, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

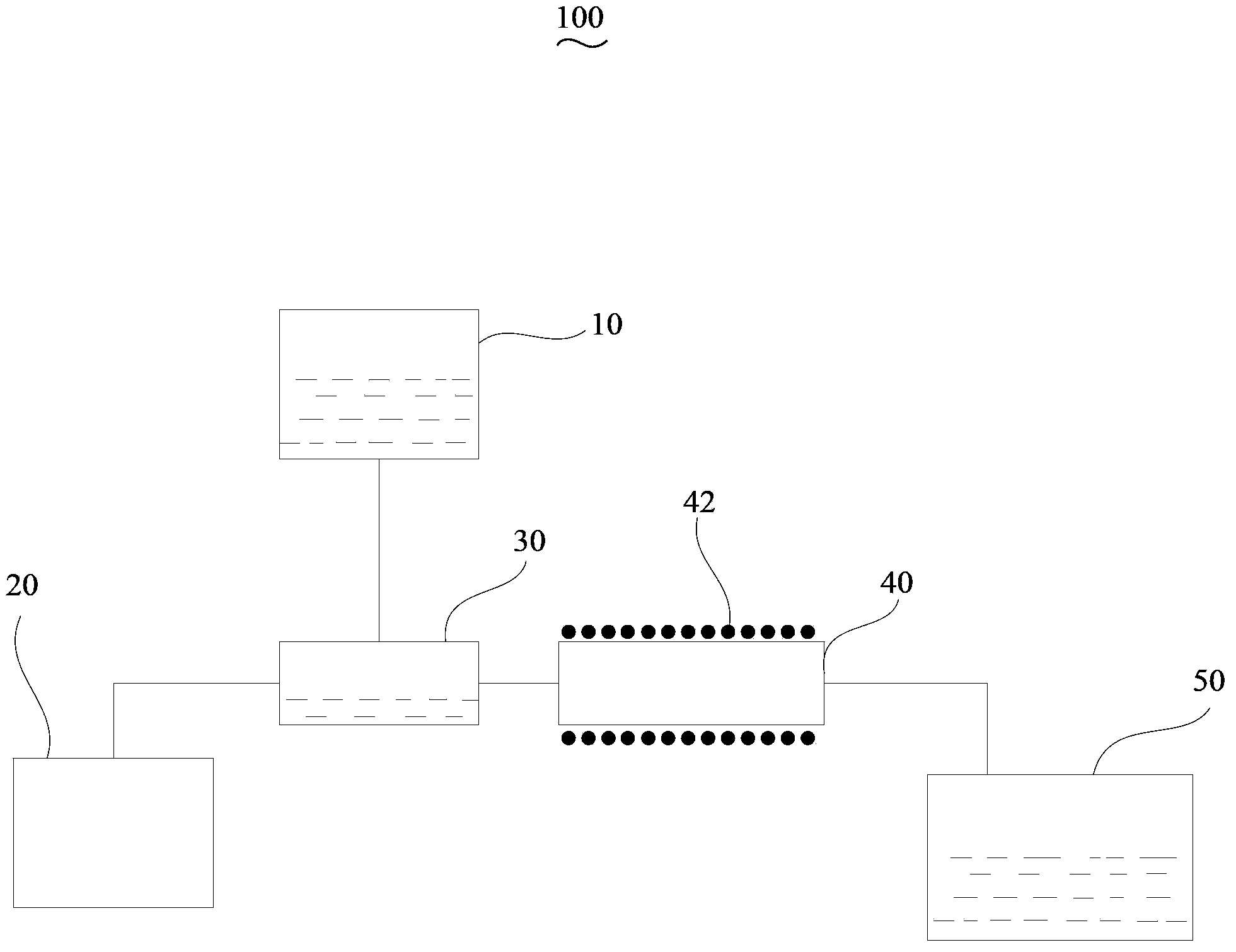

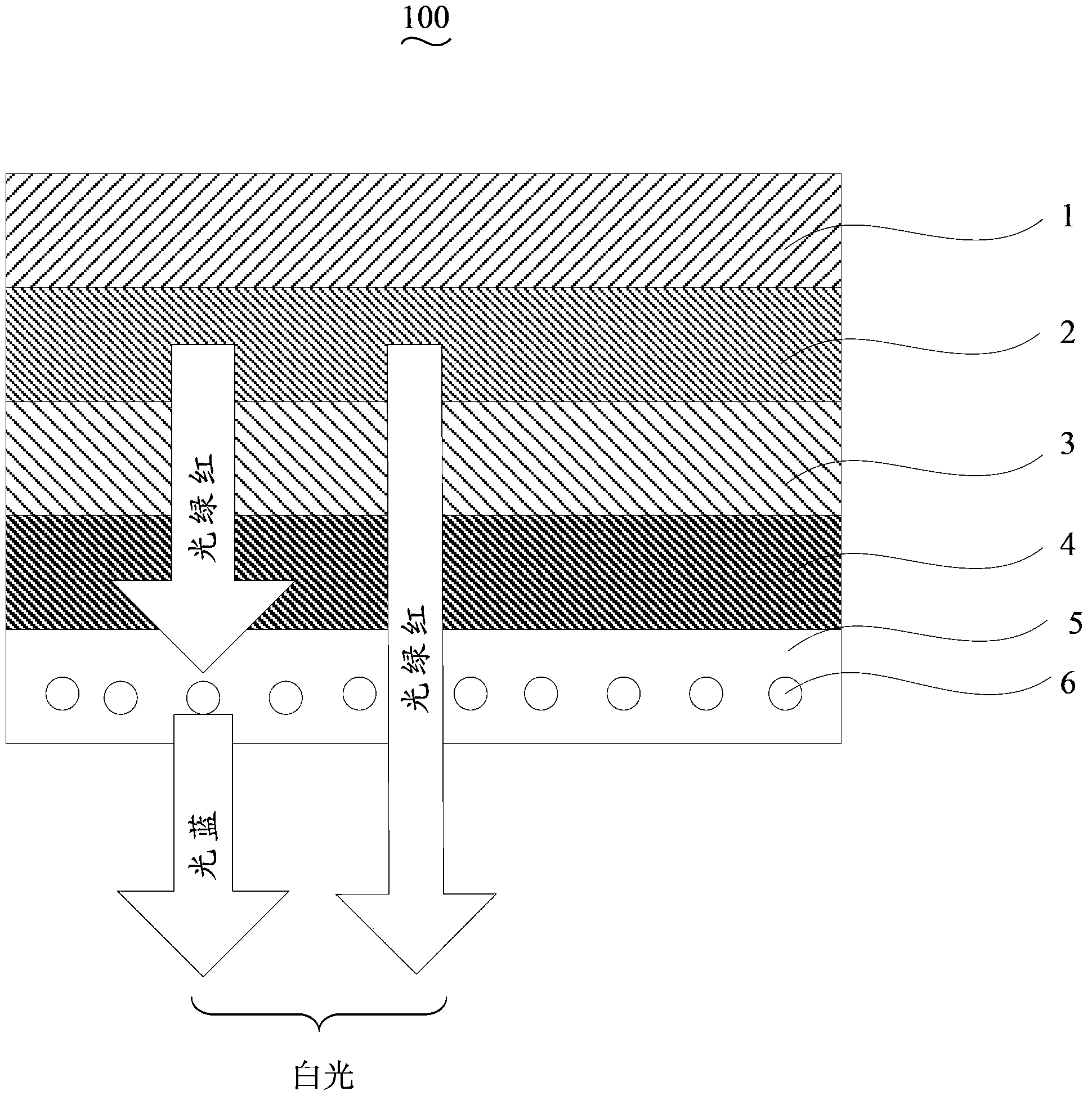

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned thulium-holmium co-doped zirconia glass up-conversion luminescent material comprises the following steps;

[0029] Step S101, according to ZrO 2 :xTm 3+ ,yHo 3+ The stoichiometric ratio of each element weighs ZrO 2 , Tm 2 o 3 and Ho 2 o 3 Powder, wherein, x is 0.002~0.06, and y is 0.002~0.04.

[0030] Preferably, x is 0.03 and y is 0.01.

[0031] It can be understood that this step can also be based on the molar ratio (0.9~0.996): (0.001~0.03):

[0032] (0.001~0.02) weigh ZrO 2 , Tm 2 o 3 and Ho 2 o 3 Powder.

[0033] Step S102 , dissolving the weighed powder in nitric acid to prepare a solution with a metal cation concentration of 0.5 mol / L-3 mol / L.

[0034] The metal cation in the solution is Zr 4+ , Tm 3+ and Ho 3+ .

[0035] In this embodiment, the concentration of metal cations is 0.3 mol / L-3 mol / L.

[0036] Preferably, the step of dissolving the weighed powder in nitric acid to prepare a solution fu...

Embodiment 1

[0051] Weigh ZrO 2 , Tm 2 o 3 and Ho 2 o 3 The powder, whose molar weights are 0.96mmol, 0.015mmol and 0.005mmol respectively, is dissolved in nitric acid to prepare a 1.5mol / L solution, and 0.01mol / L polyethylene glycol additive is added. Then put the solution into the atomization device, and then feed 3 L / min of argon gas into the atomization device. The solution precursor enters a quartz tube with a temperature of 180°C along with the argon carrier gas to generate the precursor, wherein the diameter of the quartz tube is 95mm and the length is 1.4m. Then the phosphor enters the condenser along with the airflow, and is finally collected by the microporous acid-resistant filter funnel. Collect the precursor of the phosphor, place it in a temperature-programmed furnace and calcinate for 3 hours at a calcining temperature of 1100°C to obtain ZrO 2 :0.03Tm 3+ , 0.01Ho 3+ Up-converting phosphors.

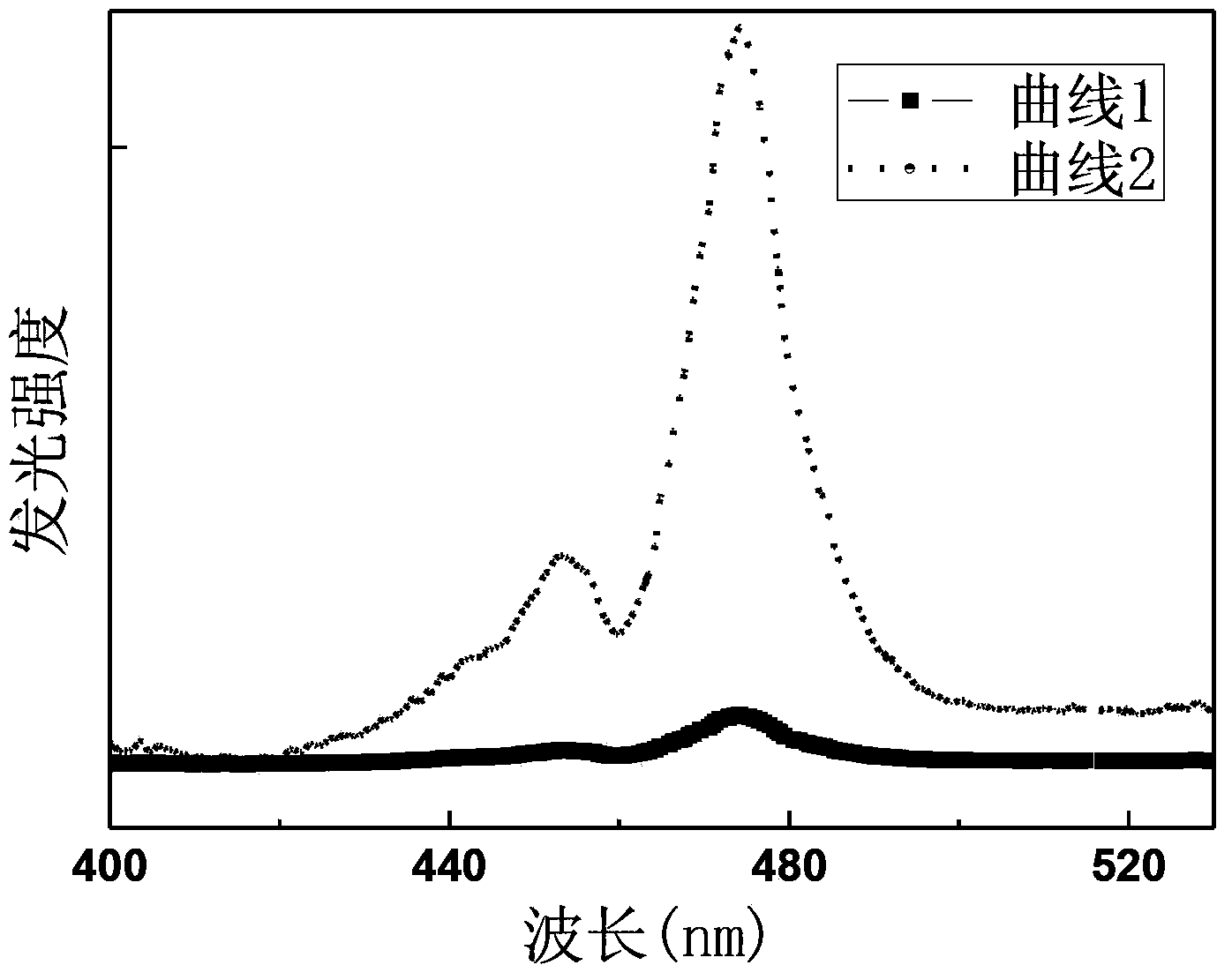

[0052] see image 3 , image 3 The middle curve 1 is the photoluminesce...

Embodiment 2

[0055] Weigh ZrO 2 , Tm 2 o 3 and Ho 2 o 3 Powder, the molar weight of which is 0.95mmol, 0.03mmol, 0.02mmol respectively, is dissolved in nitric acid to prepare a 3mol / L solution, and 0.05mol / L polyethylene glycol additive is added. Then put the solution into the atomization device, and then feed 15 L / min argon gas into the atomization device. The solution precursor enters a quartz tube with a temperature of 220°C along with the argon carrier gas to generate the precursor, wherein the diameter of the quartz tube is 150mm and the length is 3m. Then the phosphor enters the condenser along with the airflow, and is finally collected by the microporous acid-resistant filter funnel. Collect the precursor of the phosphor powder, place it in a temperature-programmed furnace and calcinate it for 5 hours, and the calcining temperature is 1300°C to obtain ZrO 2 :0.06Tm 3+ , 0.04Ho 3+ Up-converting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com