Method of Reducing the Acid Corrosivity of Oil

An etchant and catalyst technology, which is used in the field of converting acid in oil into non-corrosive substances, can solve problems such as increased energy consumption, catalyst poisoning, and low catalyst efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

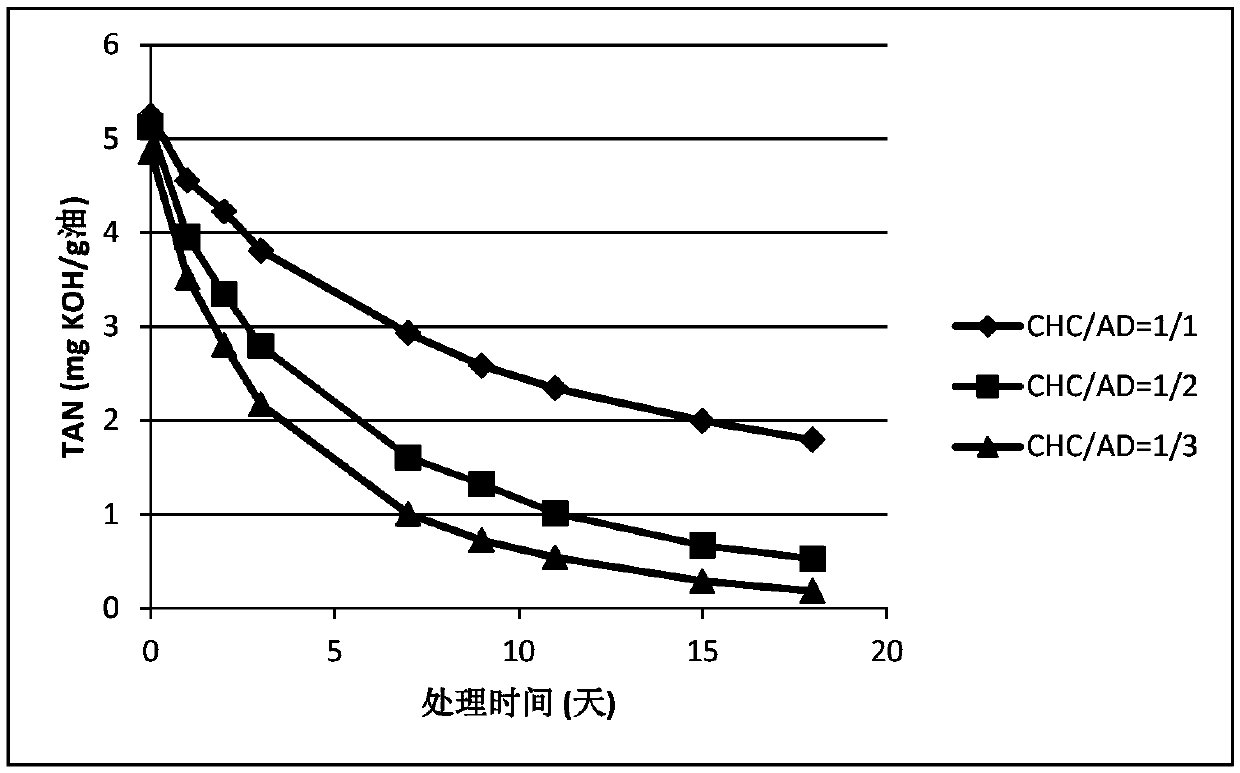

[0065] In this example, the acid-containing oil sample used is a dodecane solution of cyclohexanecarboxylic acid formed by dissolving cyclohexanecarboxylic acid in a dodecane solution, and its total acid value is 5 mgKOH / g oil. In order to carry out comparative analysis, three experiments with the molar ratios of cyclohexanecarboxylic acid and aziridine (CHC / AD) being 1 / 1, 1 / 2 and 1 / 3 were carried out respectively. figure 1 A graph of the total acid number as a function of treatment time for the three trials is shown. Such as figure 1 As shown, increasing the amount of aziridine can increase the decrease rate of total acid value.

example 2

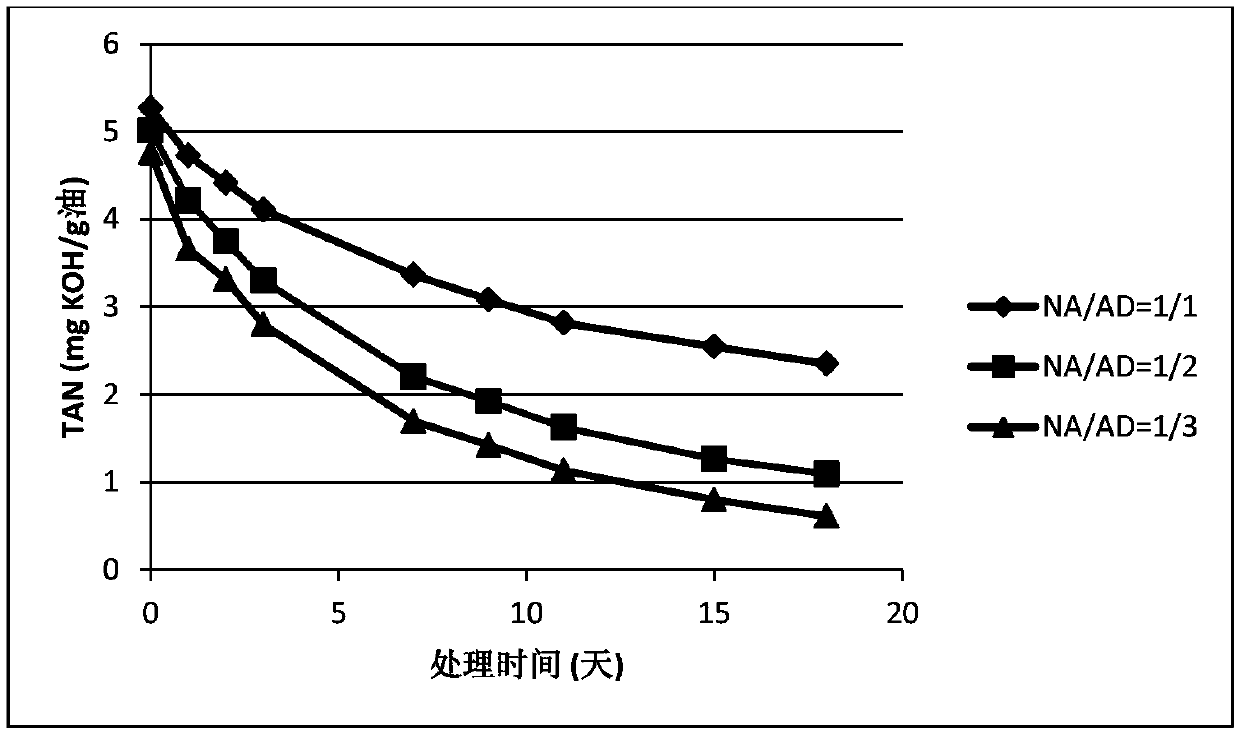

[0067] In this example, the acid-containing oil sample used is a solution of naphthenic acid in dodecane formed by dissolving naphthenic acid in dodecane solution, and its total acid value is 5 mgKOH / g oil. For comparative analysis, three experiments with the molar ratio of naphthenic acid to aziridine (NA / AD) being 1 / 1, 1 / 2 and 1 / 3 were carried out respectively. figure 2 A graph of the total acid number as a function of treatment time for the three trials is shown. Such as figure 2 Shown, described test to the dodecane solution of naphthenic acid and the test to the dodecane solution of cyclohexanecarboxylic acid in example 1 obtain similar effect, increase aziridine consumption and all can increase the percentage of total acid value reduce speed.

[0068] by comparison figure 1 and figure 2 It can be found that under the above test conditions, the reaction rate of naphthenic acid is less than that of cyclohexanecarboxylic acid. Such as figure 1 As shown, it takes 10...

example 3

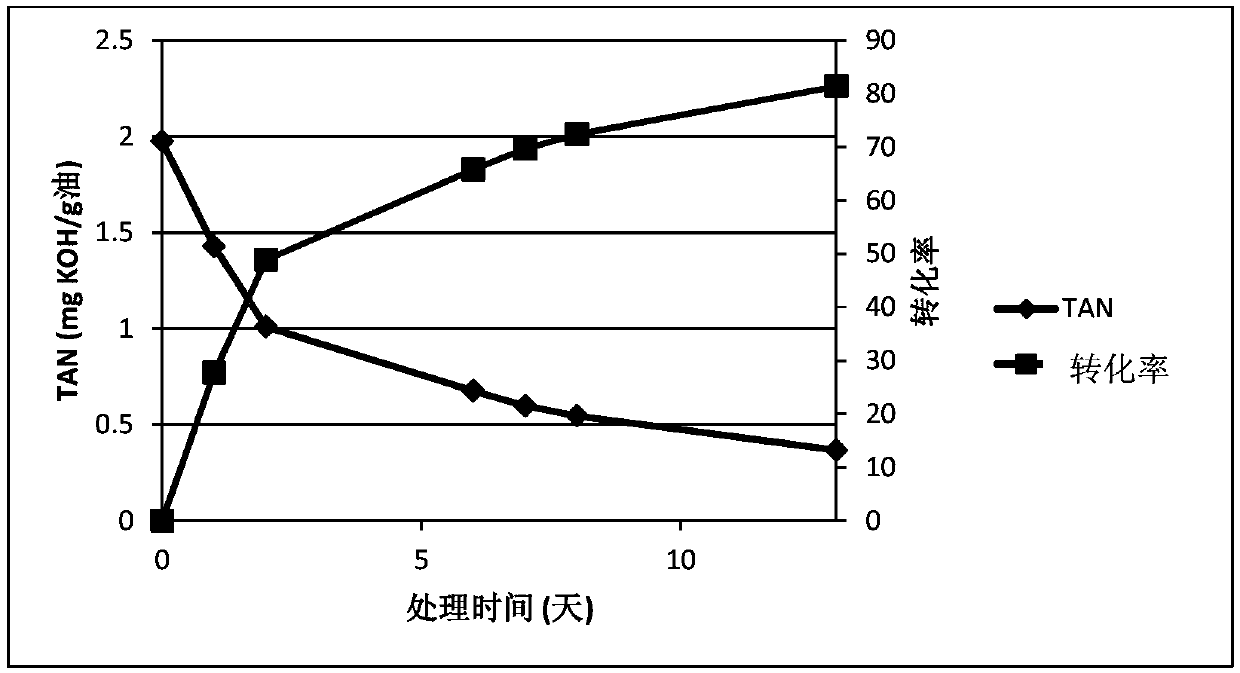

[0070] In this example, high-acid crude oil with a total acid value of 1.97 mgKOH / g oil purchased from Bohai Oilfield was used as the sour oil sample. The molar ratio of aziridine to acid in the oil is 3. image 3 The curves of total acid value and acid conversion rate as a function of treatment time are shown. The total acid value decreased rapidly in the first 2 days, and then the total acid value decreased slowly. It took approximately 4 days to achieve half of the acid conversion in the crude and approximately 10 days to reduce the total acid number below 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com