A kind of pretreatment method of traditional Chinese medicine residue classification and utilization and its application

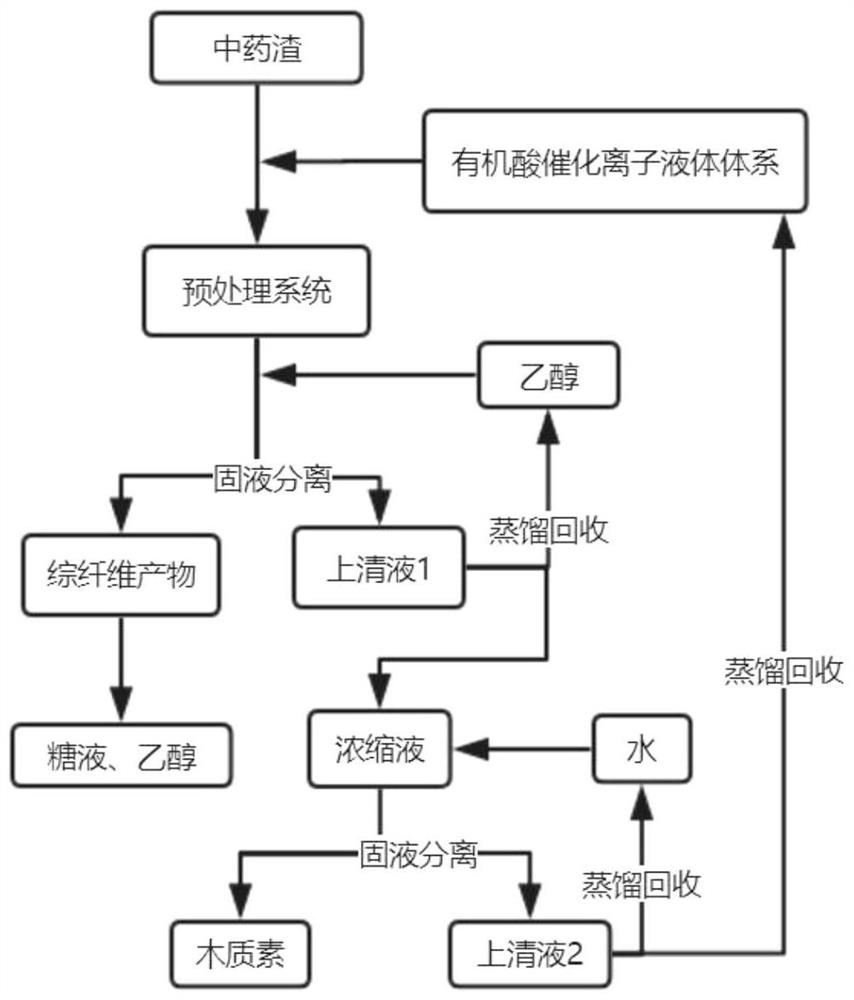

A technology of pretreatment and traditional Chinese medicine dregs, which is applied in the direction of fiber raw material treatment, pulping with organic compounds, papermaking, etc., can solve the problems of insufficient consideration of lignin recovery and value-added utilization, loss of carbohydrate components of herbal dregs, and limited fiber Recycling and utilization of raw materials and other issues, to achieve the effect of saving process costs, high overall utilization rate, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

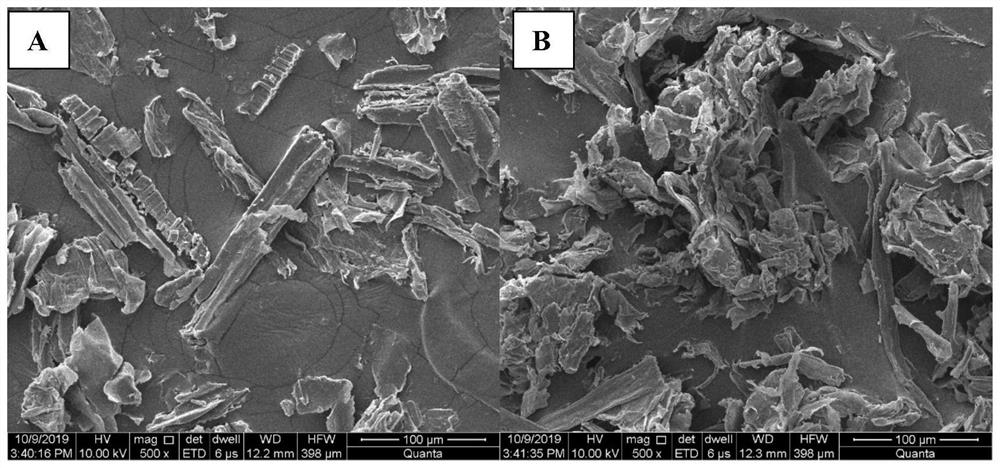

[0055] The herbal tea dregs (cellulose 36.5%, hemicellulose 18.5%, lignin 24.2%) were pulverized and passed through a 40-mesh sieve, and 5g of the dregs and the pretreatment solution were weighed and added to the reactor, and the solid-to-liquid ratio was 1:20 (g : mL), ionic liquid [Bmim]Cl in the pretreatment solution: water: p-toluenesulfonic acid = mass ratio 80%: 19%: 1%; treated at 130° C. for 2 h to obtain a treatment solution.

[0056] After the treatment solution was cooled to room temperature, under stirring with a glass rod, add a 95% (v / v) ethanol solution equivalent to 1.5 times the volume of the treatment solution, let it stand for half an hour, and centrifuge (3000rpm, 5min), and the obtained solution was named as Solution A, the obtained solid A is the enriched product of heald fibers. Then, the solid A was washed twice with an ethanol solution equivalent to 0.8 times the volume of the treatment solution, and dried at 55° C. for use. The washing solution and s...

Embodiment 2

[0060] The herbal tea dregs (cellulose 36.5%, hemicellulose 18.5%, lignin 24.2%) were pulverized and passed through a 40-mesh sieve, and 5g of the dregs and the pretreatment solution were weighed and added to the reactor, and the solid-to-liquid ratio was 1:20 (g : mL), the ionic liquid [Bmim]Cl: water: p-toluenesulfonic acid = mass ratio 70%: 28.5%: 1.5% in the pretreatment solution, and treated at 130° C. for 2 h to obtain a treatment solution.

[0061] After the treatment solution was cooled to room temperature, under stirring with a glass rod, add 1.25 times the volume of the treatment solution with 90% (v / v) ethanol solution, let it stand for half an hour, and centrifuge (4000rpm, 4min), and the obtained solution was named solution A , the obtained solid A is the enriched product of heald fibers. Then, the solid A was washed twice with an ethanol solution of 0.8 times the volume of the treatment solution, and dried at 55° C. for use. The washing solution and solution A w...

Embodiment 3

[0066] The bagasse (cellulose 36.6%, hemicellulose 23.5%, lignin 22.7%) was pulverized and passed through a 20-mesh sieve, and 5 g was weighed into the reactor, and the solid-liquid ratio was 1:15 (g:mL). The ionic liquid in the solution [Bmim]Cl: water: p-toluenesulfonic acid = mass ratio of 70%: 29%: 1%, and treated at 110° C. for 2 hours to obtain a treatment solution.

[0067] After the treatment liquid was cooled to room temperature, under stirring with a glass rod, add 1.5 times the volume of the treatment liquid with 95% (v / v) ethanol solution, let stand for half an hour, and centrifuge (3500rpm, 5min), and the obtained liquid was named solution A , the obtained solid A is the enriched product of heald fibers. Then, the solid A was washed twice with an ethanol solution of 1 times the volume of the treatment solution, and dried at 55°C for use; the washing solution and solution A were combined to obtain a liquid phase, and the ethanol in the liquid phase was recovered by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com