piston ring

A piston ring and piston ring matrix technology, applied in the field of piston rings, can solve the problems of easy wear, reduced service life of the tin layer due to hardness, affecting the air tightness of rings and cylinder liners, etc., to ensure sealing, reduce the risk of cylinder scuffing, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

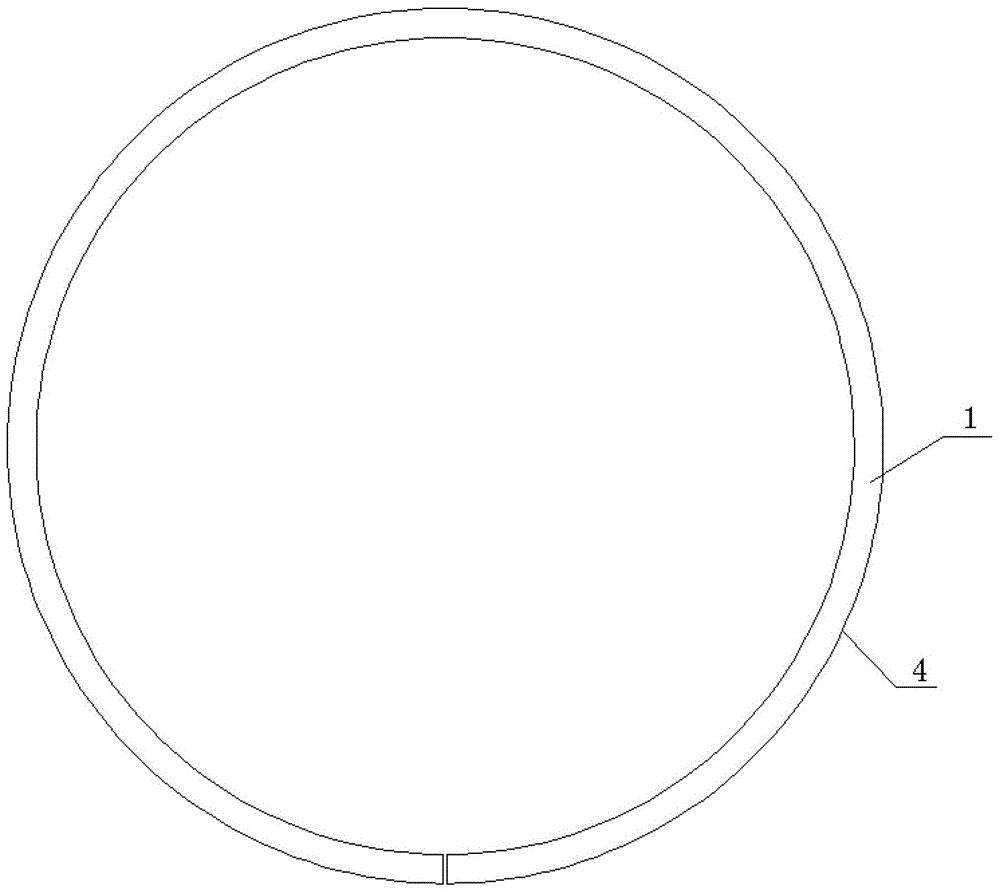

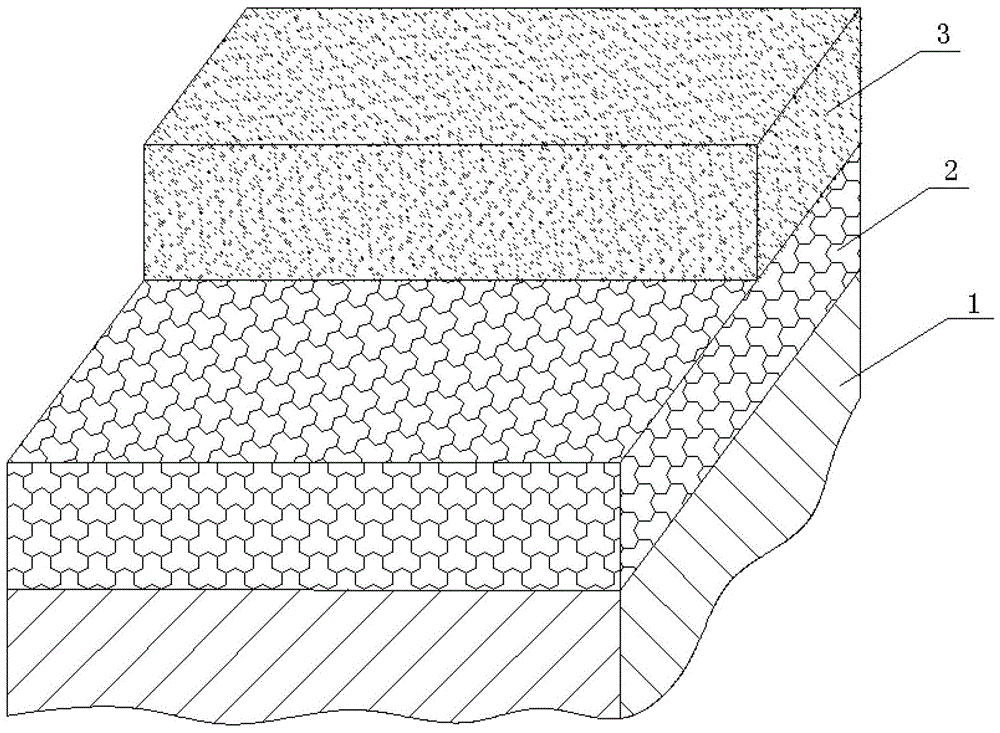

[0022] See figure 1 , the piston ring of this embodiment includes a piston ring base 1 , a chromium layer 2 and a copper layer 3 .

[0023] The chromium layer 2 is coated on the outer surface of the piston ring base 1 by means of electrochemical deposition. The copper layer 3 is coated on the outer surface of the piston ring base 1 coated with the chrome layer 2 by means of electrochemical deposition. Chromium layer 2 is ordinary hard chromium or loose-pore chromium, the hardness is greater than HV750, and the thickness is 0.2~0.5mm. The thickness of the copper layer 3 is 0.004-0.02mm, and the thickness is uniform.

[0024] Metal copper has a melting point of 1083.4°C, good thermal conductivity, and a Mohs hardness of 3. Copper plating on the outer circle of the piston ring can effectively reduce the friction coefficient between the piston ring and the cylinder liner. The copper-plated piston ring has the advantage of not producing fusion during running-in operation in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com