Device and method for detecting nitrogen trifluoride

A nitrogen trifluoride and nitrogen dioxide technology, which is applied in the field of devices for detecting nitrogen trifluoride, can solve the problems of insufficient overall performance of the instrument, unsatisfactory test results, complex decomposition products, etc., and achieves long service life and detection limit. Low, maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

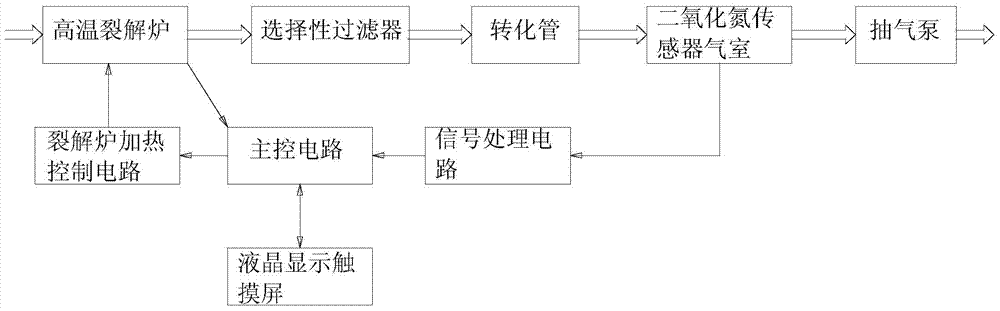

[0010] Such as figure 1 As shown, a device for detecting nitrogen trifluoride includes a high-temperature cracking furnace, a selective filter, a conversion tube, a nitrogen dioxide sensor gas chamber and an air pump, and the high-temperature cracking furnace, a selective filter, and a conversion tube , the nitrogen dioxide sensor and the suction pump are connected through pipelines in turn; there is a conversion agent in the conversion tube, and a nitrogen dioxide sensor in the gas chamber of the nitrogen dioxide sensor.

[0011] The main components of the conversion agent can be oxidants such as MnO2, FeCl3 and KMnO4.

[0012] There is a temperature sensor in the high temperature cracking furnace.

[0013] The working temperature of the high temperature cracking furnace is 600-1100°C.

[0014] The working gas flow rate of the high temperature cracking furnace is 5mL / min-500mL / min.

[0015] The measurement range of the nitrogen dioxide sensor is 1 ppm to 200 ppm.

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com