Magnetic iron-based graphite intercalation compound and preparation method thereof

A graphite intercalation and compound technology, applied in the manufacture of inductors/transformers/magnets, the magnetism of inorganic materials, electrical components, etc., can solve the problems of unsatisfactory electromagnetic shielding, complicated operation, and no magnetism, so as to avoid loss of magnetism, method Simple and efficient, good stability and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

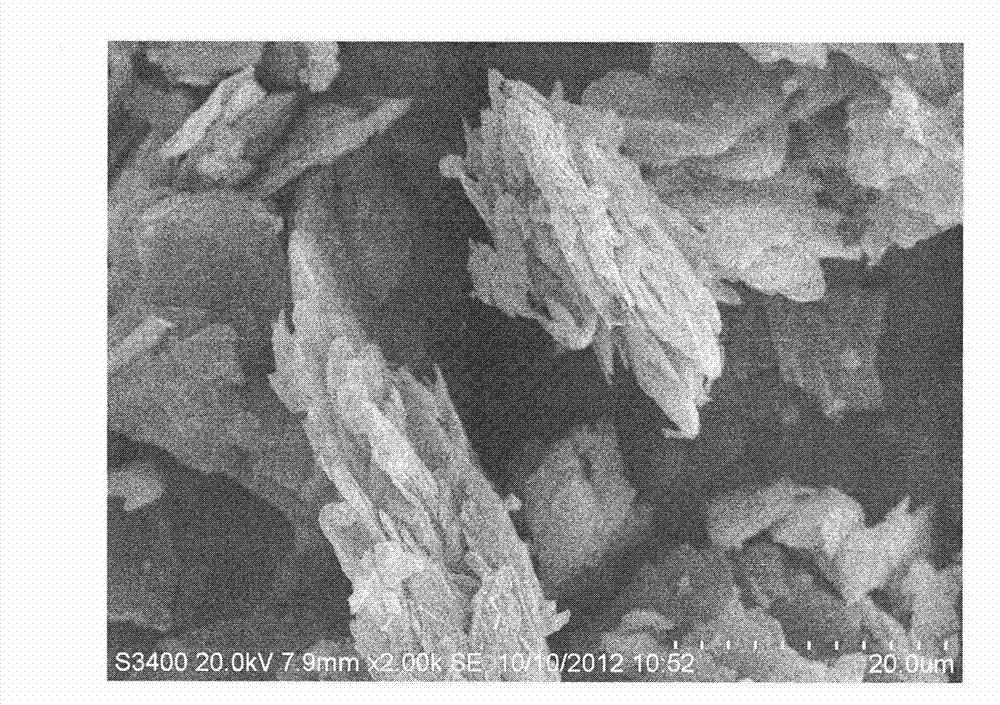

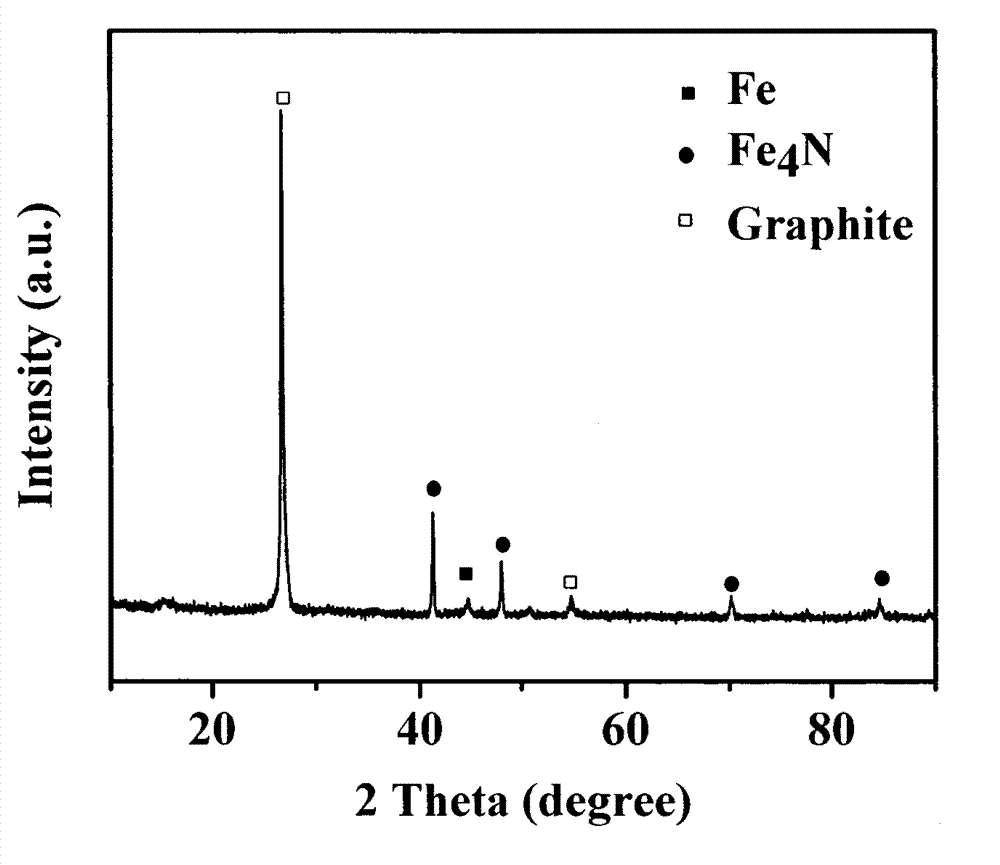

[0036] Soak 10g of 4-6μm colloidal graphite with 6mol / L nitric acid for 12 hours, filter and wash with deionized water, dry and mix with 10g FeCl 3 .6H 2 O mixed (mass ratio iron / graphite = 1 / 1), add an appropriate amount of water and stir to obtain a paste mixture, dry it at 80°C for 10 hours, grind it, heat it to 300°C in a nitrogen atmosphere, keep it for 10 hours, cool it out and use it for 5 % hydrochloric acid solution, washed in a water bath, filtered, washed with deionized water, and dried in H 2 Heating to 320°C in an air atmosphere, keeping the temperature for 10 hours, cooling and taking out the obtained product, wherein the metallic iron content is 17%.

[0037] The obtained product is added into an acrylic resin solution to disperse evenly, and is screen-printed into a ring shape, and its electromagnetic shielding effectiveness is tested in the range of 1MHz-2GHz to reach 30-50dB.

Embodiment 2

[0039] Soak 10g of 4-6μm colloidal graphite with 1mol / L sodium hypochlorite for 18 hours, filter and wash with deionized water, dry and mix with 1g FeCl 3 .6H 2 O mixed (mass ratio iron / graphite = 1 / 10), add an appropriate amount of water and stir to obtain a paste mixture, dry it at 100°C for 9 hours, grind it, heat it to 300°C in an argon atmosphere, keep it warm for 2 hours, and then raise the temperature to 400°C. Keep it warm for 3 hours, take it out after cooling, wash and filter it with a 5% hydrochloric acid solution in a water bath, wash it with deionized water, heat it to 600°C in a CO atmosphere after drying, keep it warm for 0.5 hours, take it out after cooling, and take out the obtained product, in which the metal iron content is 2%.

[0040] The obtained product is added to an acrylic resin solution to disperse evenly, and is screen-printed into a ring shape, and its electromagnetic shielding effectiveness is tested in the range of 1MHz-2GHz to reach 32-48dB.

Embodiment 3

[0042] Soak 10g of 4-6μm colloidal graphite with 1mol / L perchloric acid for 1 hour, filter and wash with deionized water, dry and mix with 20g FeCl 3 .6H 2 O mixed (mass ratio iron / graphite = 1 / 0.5), add an appropriate amount of water and stir to obtain a paste mixture, dry it at 110°C for 7 hours, grind it, heat it to 300°C in a helium atmosphere, keep it warm for 1 hour, and heat up to 450°C. Insulate for 2 hours, take it out after cooling, wash and filter with 5% hydrochloric acid solution in a water bath, wash with deionized water, and dry in NH 3 Heating to 350°C in an air atmosphere, keeping the temperature for 8 hours, cooling and taking out the obtained product, wherein the metallic iron content is 29%.

[0043] The obtained product is added to an acrylic resin solution to disperse evenly, and is screen-printed into a ring shape, and its electromagnetic shielding effectiveness is tested in the range of 1MHz-2GHz to reach 30-46dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com