Chained atmosphere furnace and sintering method for producing crystalline silicon photovoltaic cell

A technology of photovoltaic cells and atmosphere furnaces, applied in electrical components, furnaces, circuits, etc., can solve problems such as inability to provide effective references, achieve the effects of reducing nitrogen consumption, stable transmission, and preventing battery oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

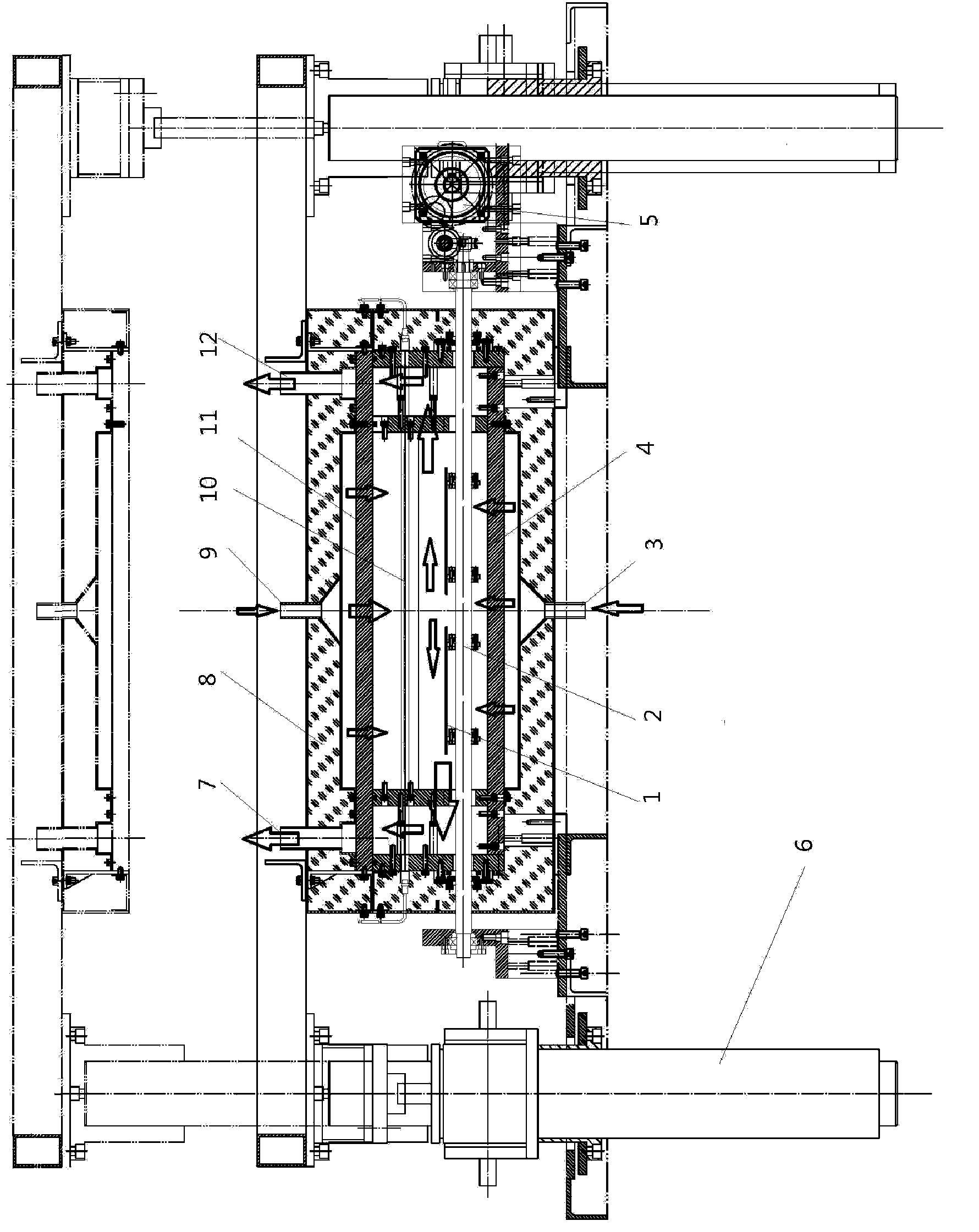

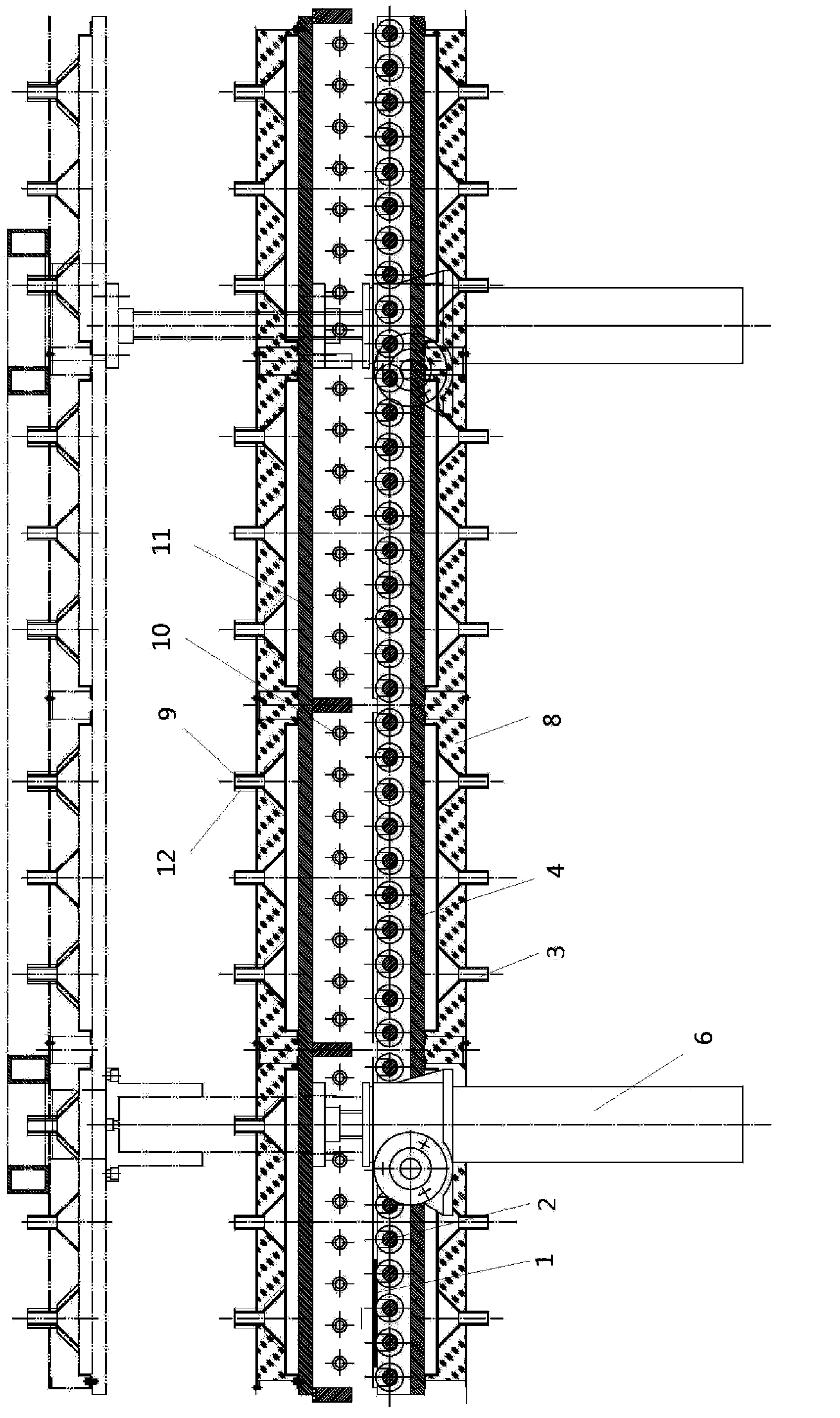

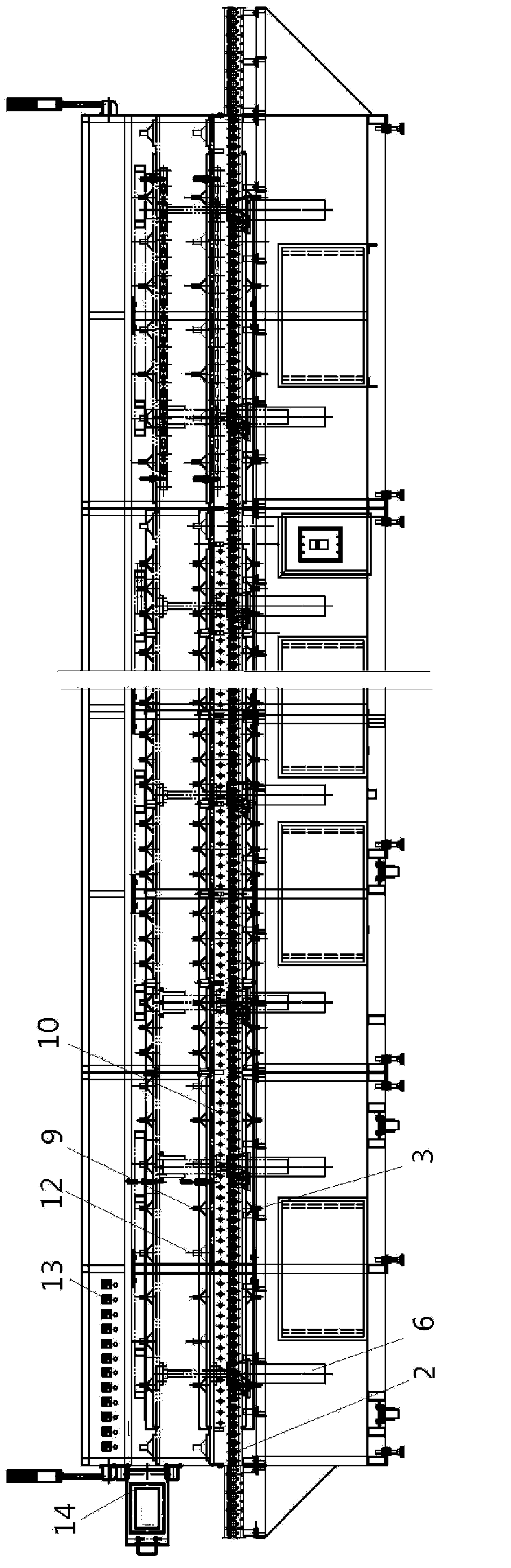

[0036] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 shown,

[0037] A chain atmosphere furnace used in the production of crystalline silicon photovoltaic cells, the internal chamber of the equipment is isolated from the outside;

[0038] There is a conveying structure of roller 2, and the roller installed on the roller conveys the crystalline silicon photovoltaic cells from one end of the furnace body to the other end;

[0039] The temperature control of the equipment adopts double temperature control, that is, the heated nitrogen enters the furnace body through pipes 3 and 9, and the overall temperature is regulated again by the infrared heating lamp 10 inside the furnace body;

[0040] The space passing through the photovoltaic cells in the middle of the equipment furnace is the process chamber, and the two sides of the process chamber are exhaust chambers;

[0041] The upper cover of the equipment furnace body is connected to the upper cover lifting device...

Embodiment 2

[0049] Example 2: as figure 1 , figure 2 , image 3 , Figure 4 shown,

[0050] A chain atmosphere furnace used in the production of crystalline silicon photovoltaic cells. The internal chamber of the equipment is isolated from the outside. After the clean nitrogen is introduced, the positive pressure inside the chamber can be maintained to ensure that the interior of the chamber is clean and can prevent crystalline silicon When the photovoltaic cell 1 is oxidized by air when passing through the equipment, such as figure 1 and figure 2 ;

[0051] The roller 2 conveying structure is adopted, and the roller installed on the roller 2 conveys the crystalline silicon photovoltaic cell 1 from one end of the furnace body to the other end;

[0052] The temperature control of the equipment adopts double temperature control, that is, the heated nitrogen gas enters the inside of the furnace body through the pipeline, and the overall temperature is regulated again through the infr...

Embodiment 3

[0066] Example 3: as figure 1 , figure 2 , image 3 , Figure 4 shown,

[0067] A sintering method for a chain atmosphere furnace applied to the production of crystalline silicon photovoltaic cells, comprising the following steps;

[0068] To prevent the nickel metal used in photovoltaic cells from oxidizing under high temperature process conditions, nitrogen gas is introduced into the entire internal cavity of the equipment, and the gap between the lamp tube and transmission shaft passing through the cavity is sealed to reduce nitrogen consumption;

[0069] The direction of the airflow is controlled by adopting the multi-chamber and uniform flow plate method;

[0070] The heated nitrogen enters the chain atmosphere furnace from the upper inlet and the lower inlet, and evenly enters the furnace body of the chain atmosphere furnace through the upper flow plate 11 and the lower flow plate 4, and then enters the exhaust chambers on both sides, and passes through the left row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com