Low oxygen content and low nitrogen consumption control system and method for radiant tube-heated non-oxidation roller hearth furnace

A technology of radiant tube heating and low oxygen content, which is applied in the field of metallurgy, can solve the problems of affecting the economic benefits of enterprises, nodules on the furnace bottom roll surface, and spending a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

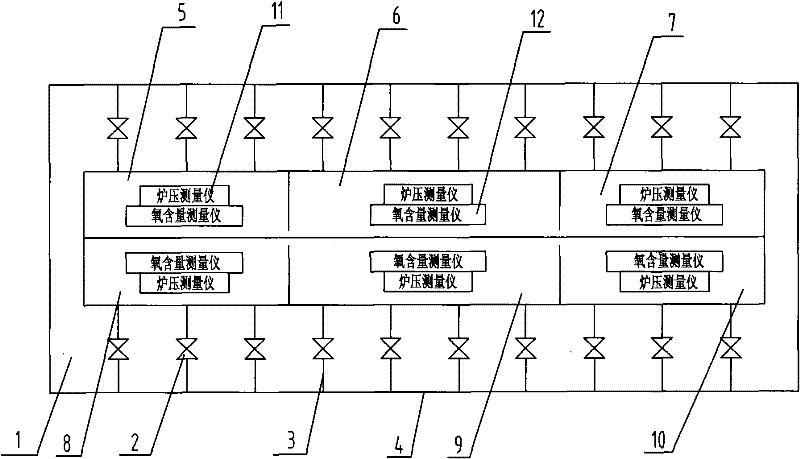

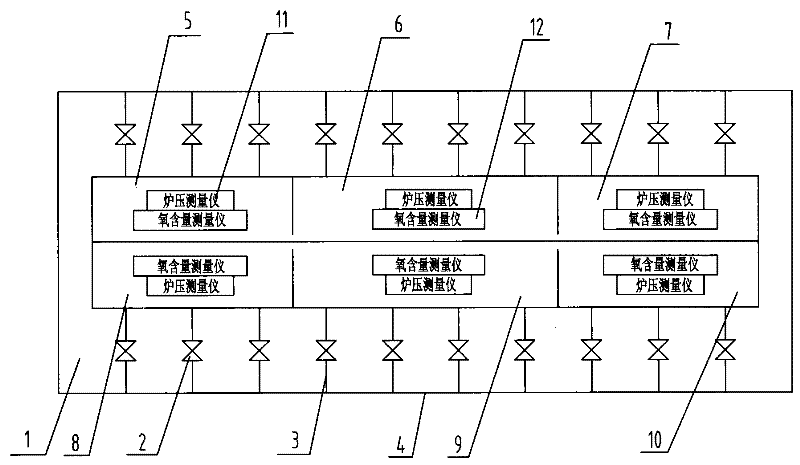

[0024] The low oxygen content and low nitrogen consumption control system of the radiant tube heating non-oxidizing roller hearth furnace in this embodiment has a structure such as figure 1 As shown, 20 nitrogen-charging electromagnetic control valves 2 are set on the furnace body 1. The nitrogen-filling electromagnetic control valves 2 are connected to the nitrogen main pipe 4 through the nitrogen gas branch pipe 3. The 20 nitrogen-charging electromagnetic control valves are arranged in two rows up and down. There are 10 in each row; the furnace body is divided into 6 zones, which are the front zone 5 of the upper furnace corresponding to the 3 nitrogen-filled electromagnetic control valves at the front end of the upper furnace, and the 4 nitrogen-filled electromagnetic control valves at the middle end of the upper furnace. Corresponding middle zone 6 of the upper furnace, rear zone 7 of the upper furnace corresponding to the three nitrogen-filled electromagnetic control valve...

Embodiment 2

[0038] The low oxygen content and low nitrogen consumption control system structure of the radiant tube heating non-oxidation roller hearth furnace of this embodiment is the same as that of embodiment 1, and the low oxygen content and low nitrogen consumption control method of the radiant tube heating non-oxidation roller hearth furnace is as follows Steps to proceed:

[0039] (1) The speed of the steel plate entering the furnace is set at 20m / min. On the one hand, the slow speed will lead to a long opening time of the furnace door and a large amount of air entering. The deviation between the signal and the actual position is aggravated, and the inconsistency between the heating model and the actual situation affects the quality of the steel plate after heat treatment;

[0040] (2) Set the nitrogen filling electromagnetic control valves corresponding to the front area of the upper furnace, the rear area of the upper furnace, the front area of the lower furnace and the re...

Embodiment 3

[0051] The low oxygen content and low nitrogen consumption control system structure of the radiant tube heating non-oxidation roller hearth furnace of this embodiment is the same as that of embodiment 1, and the low oxygen content and low nitrogen consumption control method of the radiant tube heating non-oxidation roller hearth furnace is as follows Steps to proceed:

[0052] (1) The speed of the steel plate entering the furnace is set at 30m / min. On the one hand, the slow speed will lead to a long opening time of the furnace door and a large amount of air entering. The deviation between the signal and the actual position is aggravated, and the inconsistency between the heating model and the actual situation affects the quality of the steel plate after heat treatment;

[0053] (2) Set the nitrogen filling electromagnetic control valves corresponding to the front area of the upper furnace, the rear area of the upper furnace, the front area of the lower furnace and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com