Pulp making device for producing compound fertilizer by high tower pelletizing

A high-tower granulation and compound fertilizer technology, which is applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., can solve the problems of slurry viscosity increase, unfavorable granulation, and excessive dust, so as to achieve round granules, less damaged granules, and high yield. The effect of good slurry fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

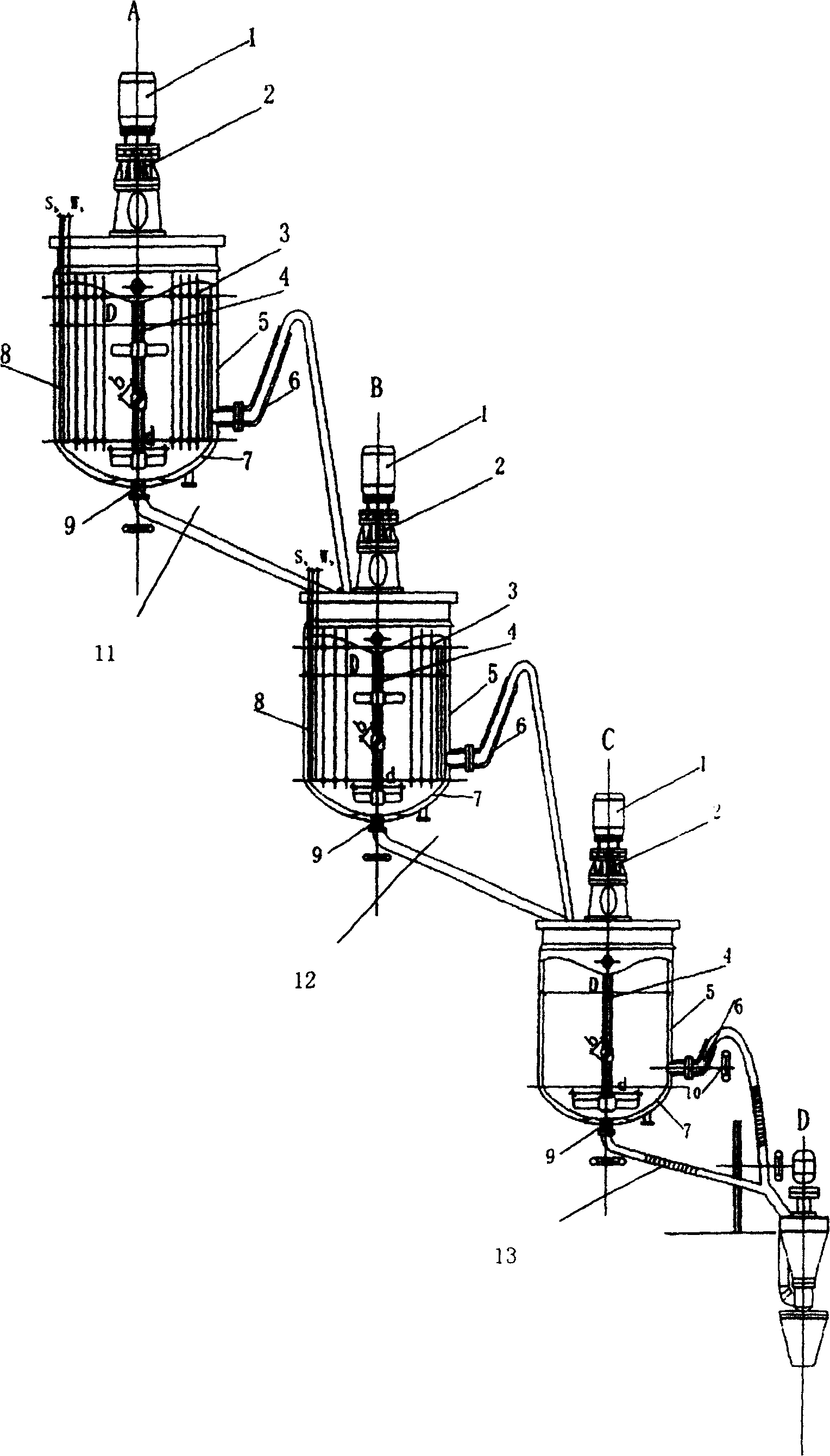

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

[0019] Referring to Fig. 1, the pulping equipment for producing compound fertilizer by high-tower granulation in this embodiment can be used to produce urea-based compound fertilizer. The cylinder inner barrel of its melting pot A is made of 304 stainless steel, and the outer layer of melting pot A is a steam integral insulation clip Cover 5 (also can be section steel insulation jacket, half-pipe insulation jacket, honeycomb insulation jacket, can adopt half-pipe jacket when producing nitro compound fertilizer). The jacket material of the insulation jacket is Q235. A layer of thermal insulation material can also be arranged outside the thermal insulation jacket to save heat energy. The pot bottom 7 of melting pot A is ellipse, and it also can be planar shape, conical. The stirring device is composed of a motor 1, a drive reducer 2, and a stirring pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com