Automatic sample injection system for greenhouse gas

An automatic sampling and greenhouse gas technology, which is applied to the analysis of materials and instruments, can solve the problems of heavy work intensity of testing personnel, poor repeatability of manual analysis, cumbersome air bag sampling, etc., to achieve high air tightness, save costs, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment specifically illustrates the system structure of the present invention.

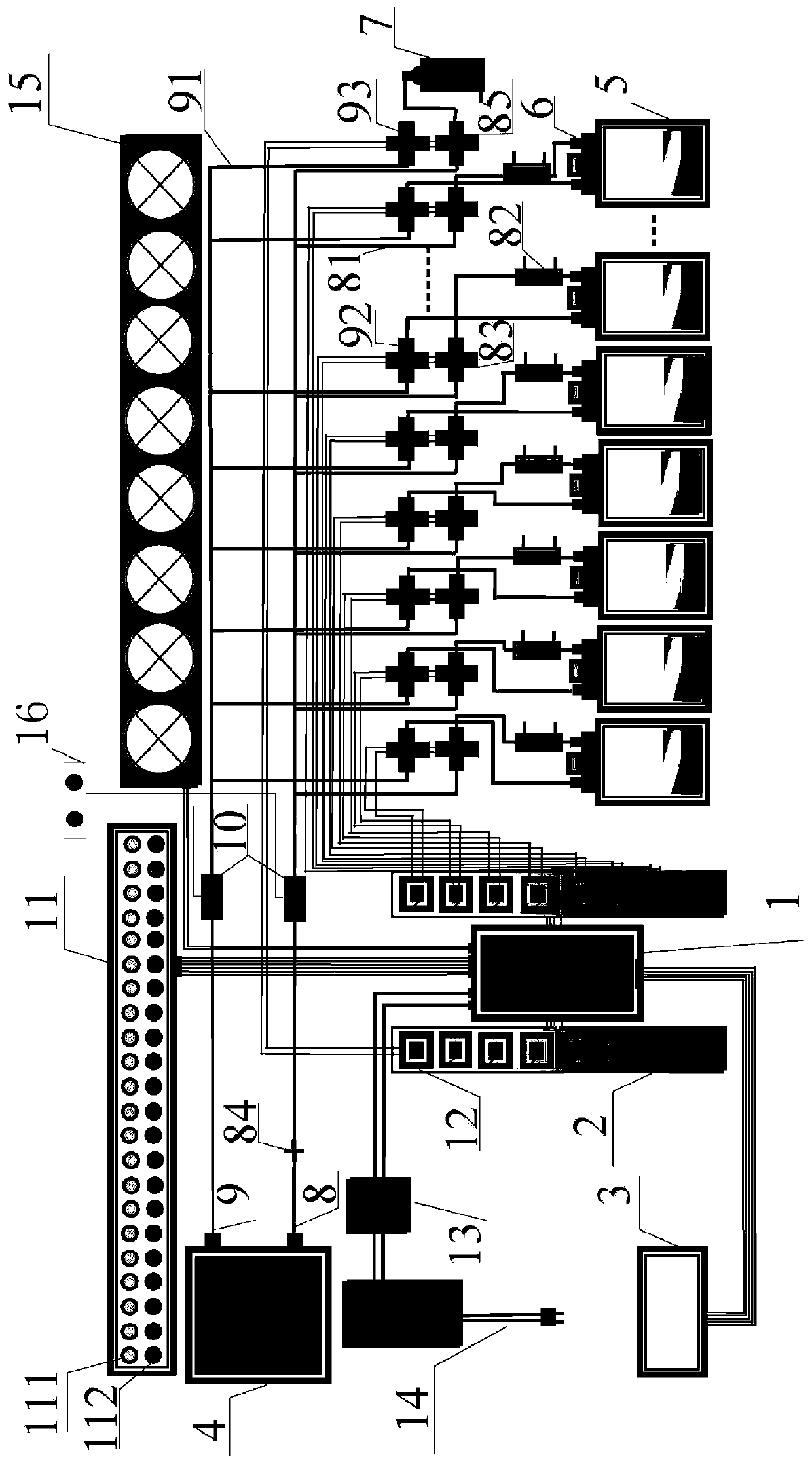

[0038] Such as figure 1 The greenhouse gas sampling system shown includes a control device 1, a relay 2, an input device 3, a solenoid valve, a gas sampling device, a gas scrubber, a quick-connect port 6, multiple groups of cultivation devices 5 and a power supply 13; the control device 1 is a single-chip microcomputer, and the input device 3 is a touch-type digital display screen.

[0039] The relay 2 is connected to the control device 1 and the solenoid valve to control the opening and closing of the solenoid valve.

[0040] The input device 3 is connected to the control device 1, and is used for inputting user-defined parameters, including the sampling order of multiple sets of culture devices, detection duration, sampling cycle and gas washing time.

[0041] The gas sampling device includes an external detector 4, an air inlet pipeline 81, an air outlet pipeline 91, a first air...

Embodiment 2

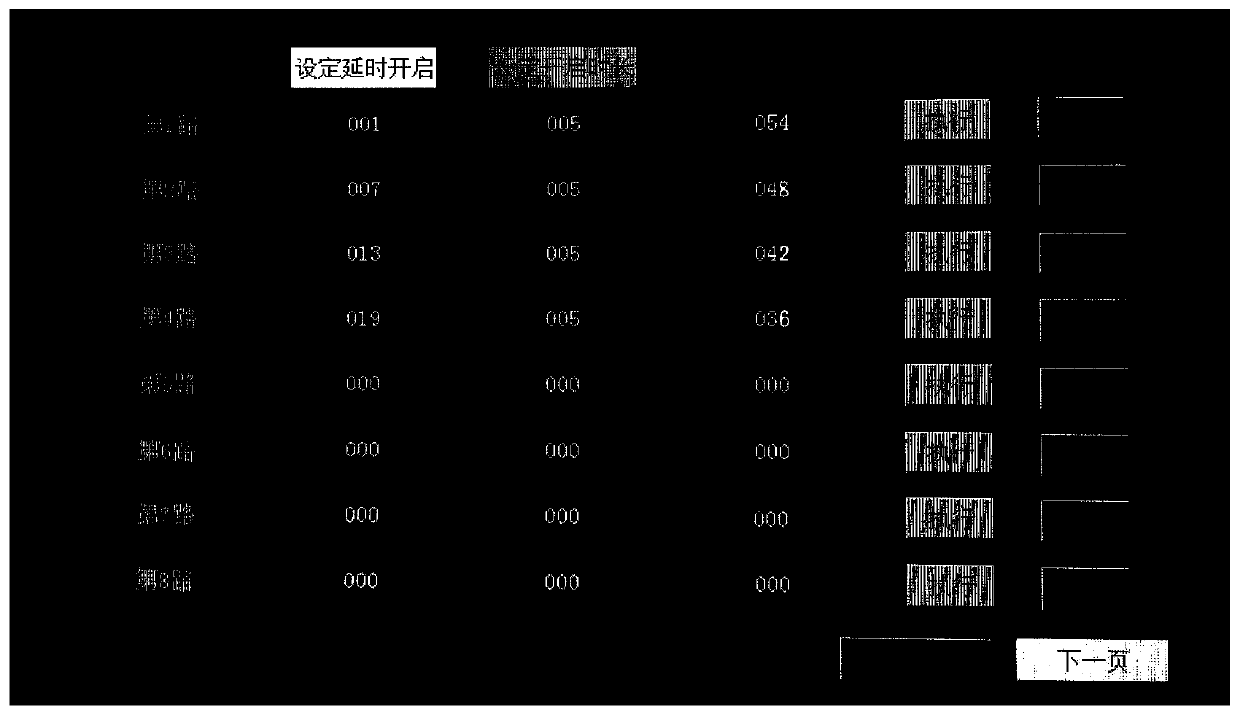

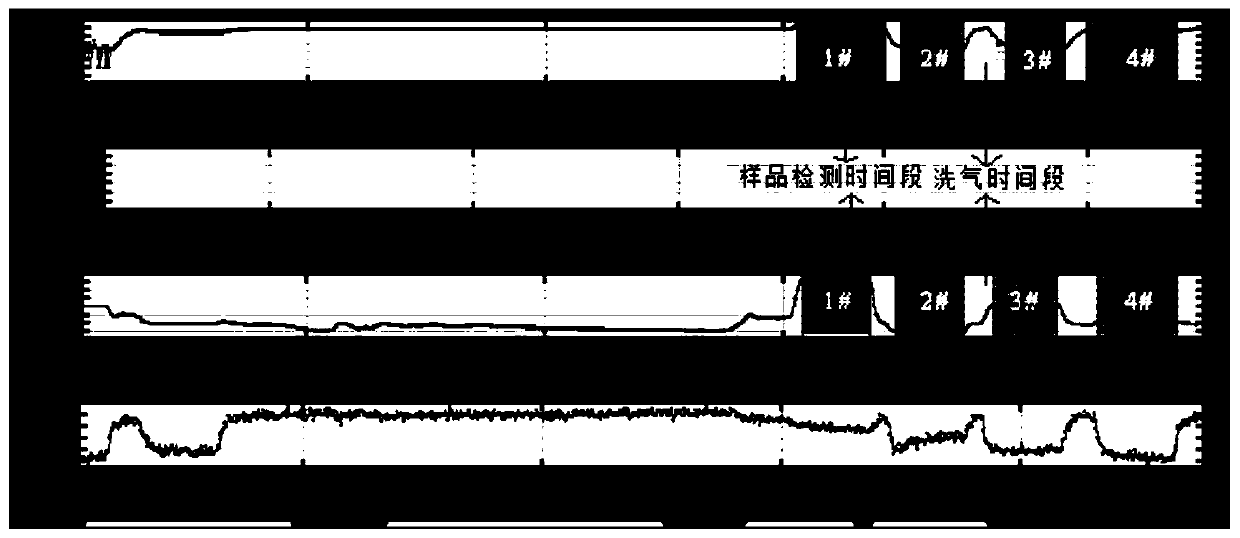

[0056] In this embodiment, the mineralization of cyanobacteria is taken as an example to illustrate the method of using the device in Embodiment 1 to carry out an automatic sampling experiment. There are 4 groups of culture bottles in this experiment, set the injection order of 1#, 2#, 3#, 4# culture bottles on the input device (touch digital display screen) as 1, 2, 3, 4, and the injection interval ( Washing time) was 1 min, the sampling detection time was 5 min, and the sampling frequency was 1 h / time. The specific parameters are set as figure 2 shown;

[0057] The i-th way: refers to the sample injection sequence, opening time, sample injection detection time, and closing time parameter settings for the i-th intake line;

[0058] Setting delay start: refers to the time setting for the start of sample injection in the i-th intake line;

[0059] Set the opening time: refers to the detection time of the i-th air intake pipeline;

[0060] Set closing time: refers to the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com