Light emitting diode flip chip packaging method based on through hole technology

A light-emitting diode and chip packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor contact, falling off, and thermal expansion and fracture of gold wire solder joints, and achieve compact structure, improved reliability, and size structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

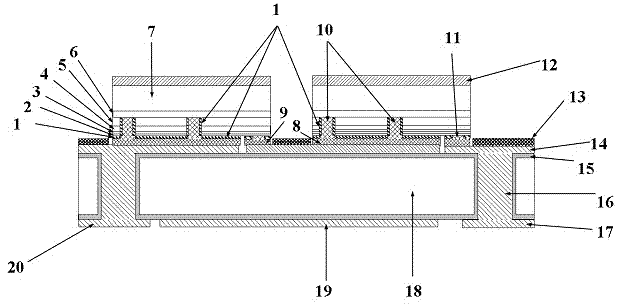

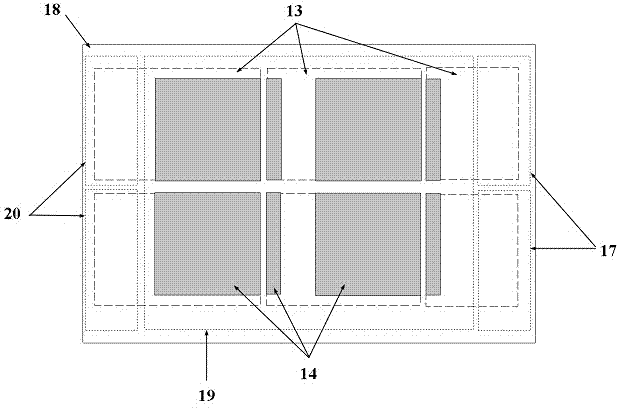

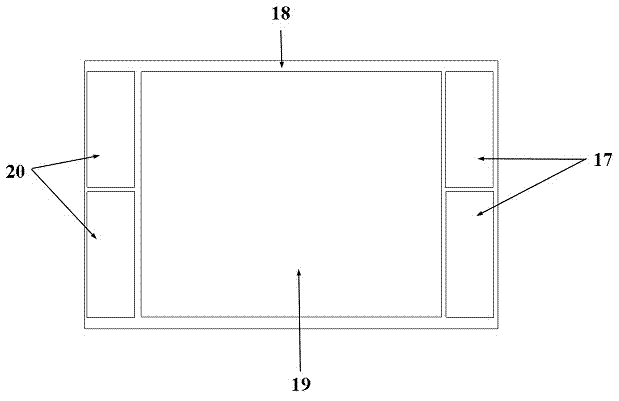

[0030] see figure 1 , figure 2 , image 3 , a flip-chip light-emitting diode chip packaging method based on through-hole technology, the process steps are as follows:

[0031] 1) On the sapphire substrate 7, n-type GaN6, light-emitting layer 5, p-type GaN4, ITO current spreading layer 3, and reflective layer 2 are sequentially grown to complete the fabrication of the light-emitting diode chip;

[0032] 2) Make blind holes on the light-emitting diode chip by etching technology or laser technology, and make through holes on the silicon substrate 18; then make the chip insulating layer 1 on the surrounding walls of the blind holes of the chip by physical chemical vapor deposition, Fabricate the substrate insulating layer 15 on the through hole peripheral wall of the silicon substrate 18, etch the chip insulating layer 1 on the bottom surface of the blind hole of the chip by plasma etching to expose the n-type GaN 6 , and then place it on the blind hole of the chip by evaporati...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, the difference is that the silicon substrate 18 is replaced with a ceramic base substrate, such as an alumina substrate, an AlN substrate, and in Embodiment 1, the substrate insulating layer 15 before the metallization of the silicon substrate 18 is made The process is no longer needed, and everything else is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com