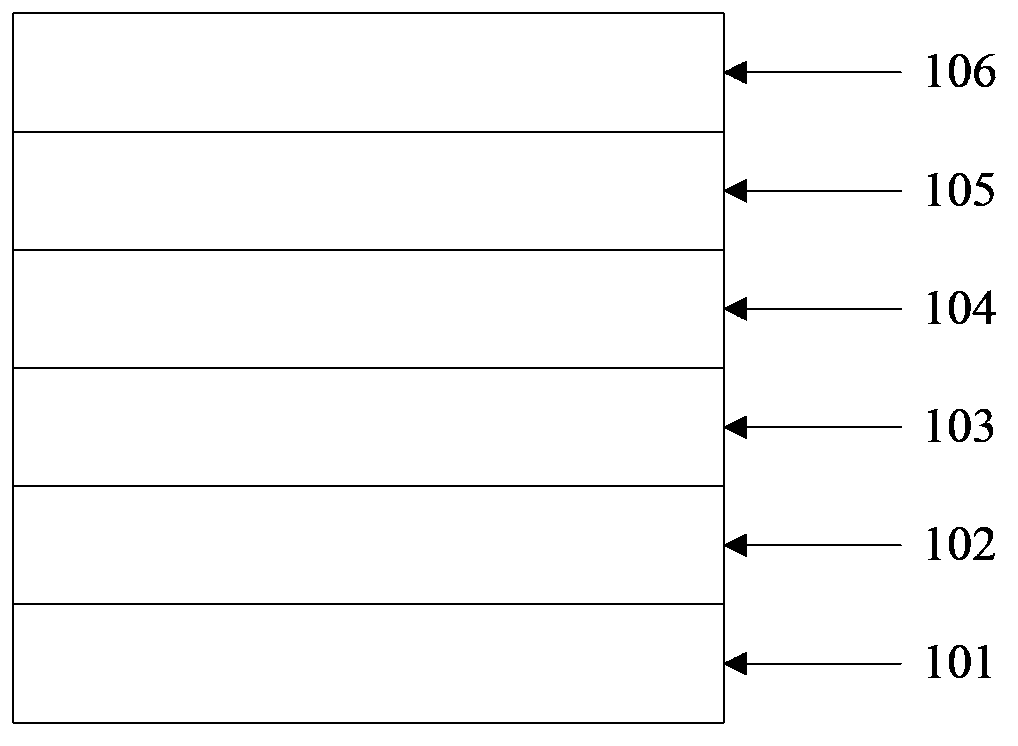

Inverted top-emitting organic electroluminescence device and manufacturing method thereof

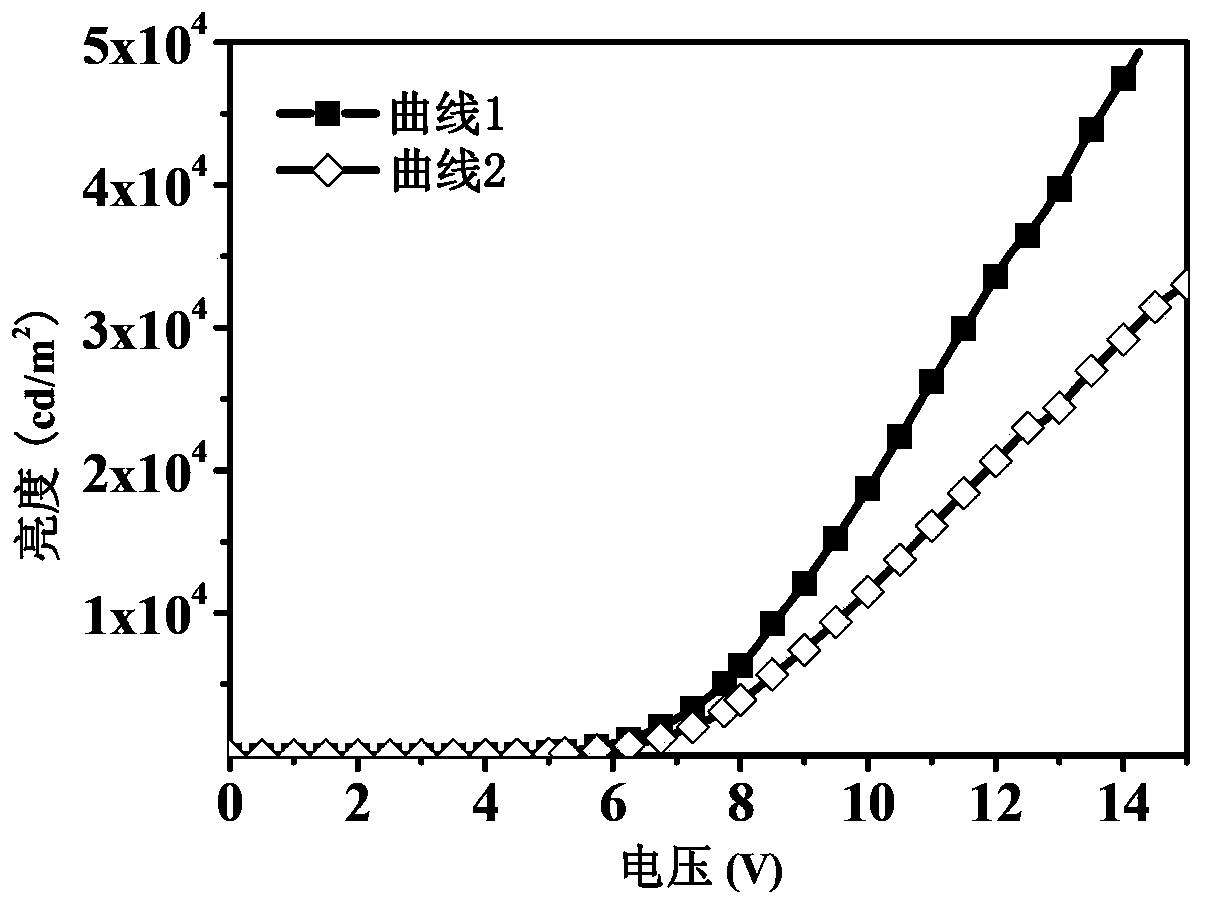

A luminescence and top-emission technology, which is applied in the manufacture of organic semiconductor devices, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of difficult evaporation temperature, inconsistent evaporation temperature, low luminous efficiency of devices, etc., and achieve enhanced transmission rate, Enhance the front luminous intensity and improve the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned inverted top-emitting organic electroluminescent device, comprising the following steps:

[0035] S1. First, the cathode substrate is subjected to photolithography treatment, and then ultrasonically cleaned with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic pollutants on the surface of the cathode substrate;

[0036] S2, preparation of electron transport layer:

[0037] First, the carbon aerogel and the electron transport material are mixed according to the mass ratio of 0.1:1-2 to form a doped mixed material;

[0038] Second, add the doped mixed material into the solvent to form a mixed solution with a concentration of 5-20%;

[0039] Finally, the mixed solution is spin-coated on the surface of the conductive cathode layer of the cathode substrate, and the thickness is controlled to be 40-200nm, and after drying, the electron transport layer ...

Embodiment 1

[0049] 1. First, photolithographically process the ITO glass, cut it into the required size, and then use detergent, deionized water, acetone, ethanol, and isopropanol to ultrasonically clean it for 15 minutes to remove organic pollutants on the surface of the ITO glass;

[0050] 2. Preparation of electron transport layer:

[0051] First, the carbon airgel with a particle size of 20nm and TPBi are mixed according to the mass ratio of 0.5:2 to form a doped mixed material;

[0052] Secondly, the doping mixed material is added to chlorobenzene to form a mixed solution with a concentration of 10%;

[0053] Finally, the mixed solution is spin-coated on the ITO layer surface of the ITO glass, and the thickness is controlled to be 150nm; after drying, the electron transport layer is obtained, which is expressed as carbon airgel: TPBi;

[0054] 3. On the surface of the electron transport layer, the vapor-deposited light-emitting layer is sequentially stacked, and the material is Alq ...

Embodiment 2

[0057] 1. First, photolithographically process the IZO glass, cut it into the required size, and then use detergent, deionized water, acetone, ethanol, and isopropanol to ultrasonically clean it for 15 minutes to remove organic pollutants on the surface of the IZO glass;

[0058] 2. Preparation of electron transport layer:

[0059] First, carbon aerogel with a particle size of 2nm and TAZ are mixed according to the mass ratio of 0.1:2 to form a doped mixed material;

[0060] Secondly, adding the doped mixed material into dichloromethane to configure a mixed solution with a concentration of 20%;

[0061] Finally, the mixed solution is spin-coated on the surface of the IZO layer of the IZO glass, and the thickness is controlled to be 40nm; after drying, the electron transport layer is obtained, which is expressed as: carbon airgel TAZ;

[0062] 3. On the surface of the electron transport layer, the vapor-deposited light-emitting layer is sequentially stacked, the material is DC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com