Preparation method of beta-cyclodextrin/mesoporous attapulgite composite adsorbent

An attapulgite, composite adsorption technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of lack of adsorption force, limited adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

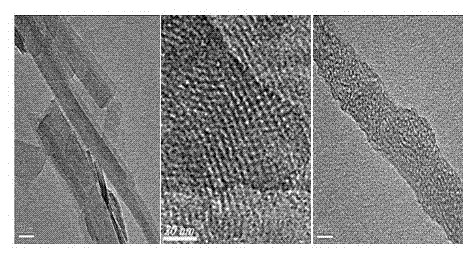

Image

Examples

Embodiment 1

[0033] 1. A preparation method of β-cyclodextrin / mesoporous attapulgite composite adsorbent, carried out according to the following steps:

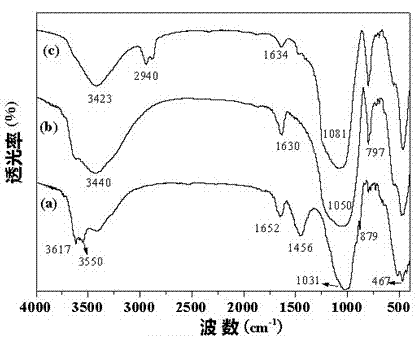

[0034] (1) Synthesis of mesoporous attapulgite

[0035] After the attapulgite material is ground, react 0.95g of ATP with 8mol / L HCl solution at 90°C for 2.0h, then cool to room temperature, filter the product, and wash it thoroughly with distilled water until it is neutral, then place it at 80°C Dried and ground into powder for later use. Dissolve 0.25g of CTAB in 10mL of deionized water, then add 0.25g of acidified ATP to form a complex, then add 0.5mol / L NaOH dropwise to adjust the pH of the complex to 12.0, and then put the complex in oil at 60°C After reacting in the bath for 2.0 h, the mixture was transferred to a reaction kettle, reacted at 100 ° C for 24 h, then cooled to room temperature, filtered, washed with distilled water and absolute ethanol until the pH was 7, dried at 80 ° C for 12 h, and then Put the obtained compound i...

Embodiment 2

[0050] 1. A preparation method of β-cyclodextrin / mesoporous attapulgite composite adsorbent, carried out according to the following steps:

[0051] (1) Synthesis of mesoporous attapulgite

[0052] After the attapulgite material is ground, react 0.98g of ATP with 7.9mol / L HCl solution at 80°C for 1.9h, then cool to room temperature, filter the product, and wash it thoroughly with distilled water until it is neutral, and then heat it at 90°C Dried and ground into powder for later use. Dissolve 0.2g of CTAB in 10mL of deionized water, then add 0.2g of acidified ATP to form a complex, then add 0.5mol / L NaOH dropwise to adjust the pH of the complex to 12.0, and then put the complex in oil at 65°C After reacting in the bath for 1.9h, the mixture was transferred to the reaction kettle, reacted at 105°C for 23h, then cooled to room temperature, filtered, washed with distilled water and absolute ethanol until neutral, then dried at 80°C for 12h, and then The obtained composite was pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com