Method for preparing slow/controlled release fertilizer by using urea coated with diatomite

A technology for coating urea and diatomaceous earth, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as low utilization rate of urea, pollution, etc., and achieve the effects of low decomposition rate, improved soil fertility, and long fertilizer effect period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First put diatomaceous earth into drying box and dry 15h at 100 DEG C, after sieving through 200~500 mesh standard sample sieves, seal for subsequent use;

[0032] Weigh different amounts of PVA, heat it to dissolve in water, then add a certain amount of PVAc, and after cooling, set the volume to form a mixed binder. The mass percentage of PVA in the mixed binder solution is 1%, and the mass percentage of PVAc 0.04%, sealed for standby;

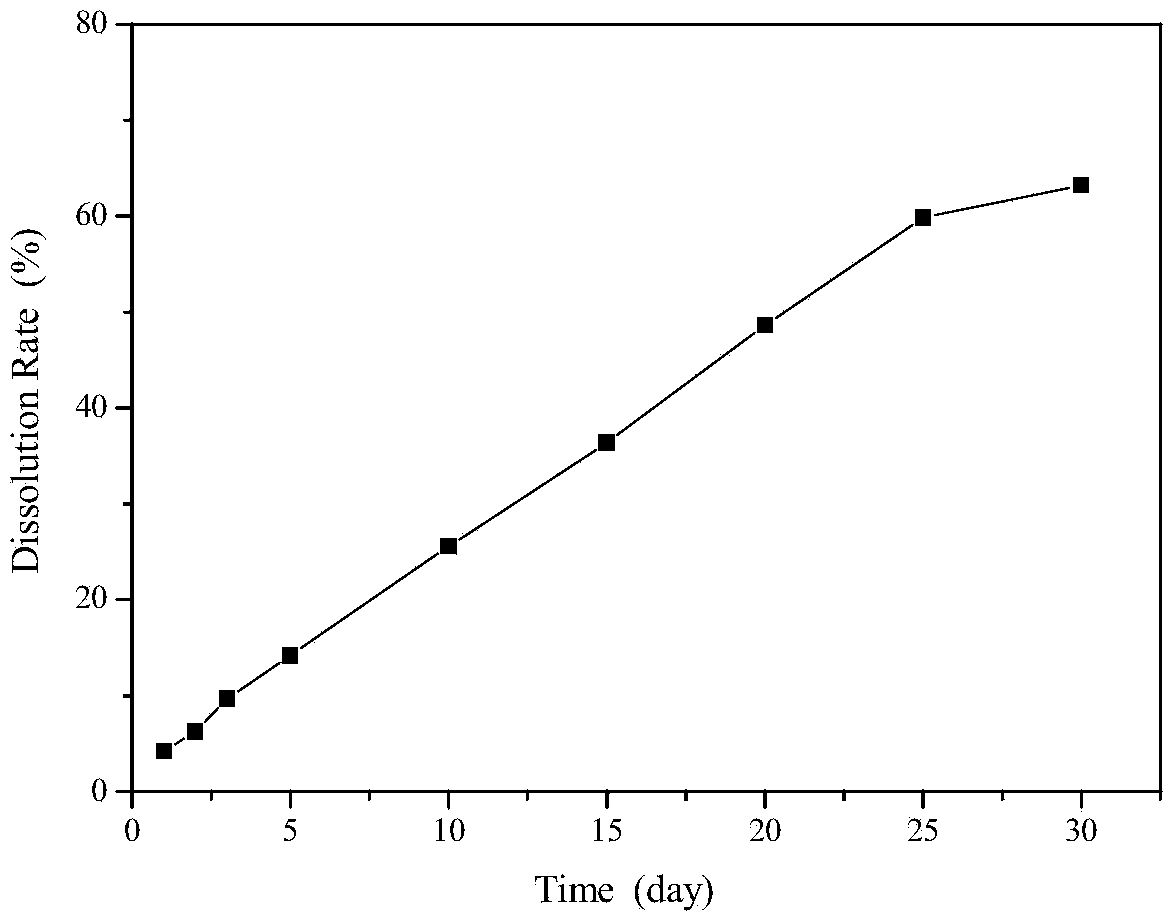

[0033] Put 90g of urea with uniform particle size into the sugar coating machine. After preheating for 5 minutes, start rolling granulation, and spray 3mL of atomized 1% PVA / 0.4PVAc binder in it, until the surface of urea granules forms a uniform layer. After adding 3.3g of diatomite powder, roll and granulate for about 4 minutes until the surface of the fertilizer granules forms a coating layer. Repeat the above process 3 times to finish adding 10g of diatomaceous earth, roll and granulate until the granules are completely dry, and ...

Embodiment 2

[0036]First put diatomaceous earth into drying oven and dry 10h at 200°C, after sieving through a 200-500 mesh standard sampling sieve, seal it for subsequent use;

[0037] Weigh different amounts of PVA, heat it to dissolve in water, then add a certain amount of PVAc, and after cooling, constant volume is configured to form a mixed binder. The mass percentage of PVA in the mixed binder solution is 3%, and the mass percentage of PVAc 0.8%, sealed for standby;

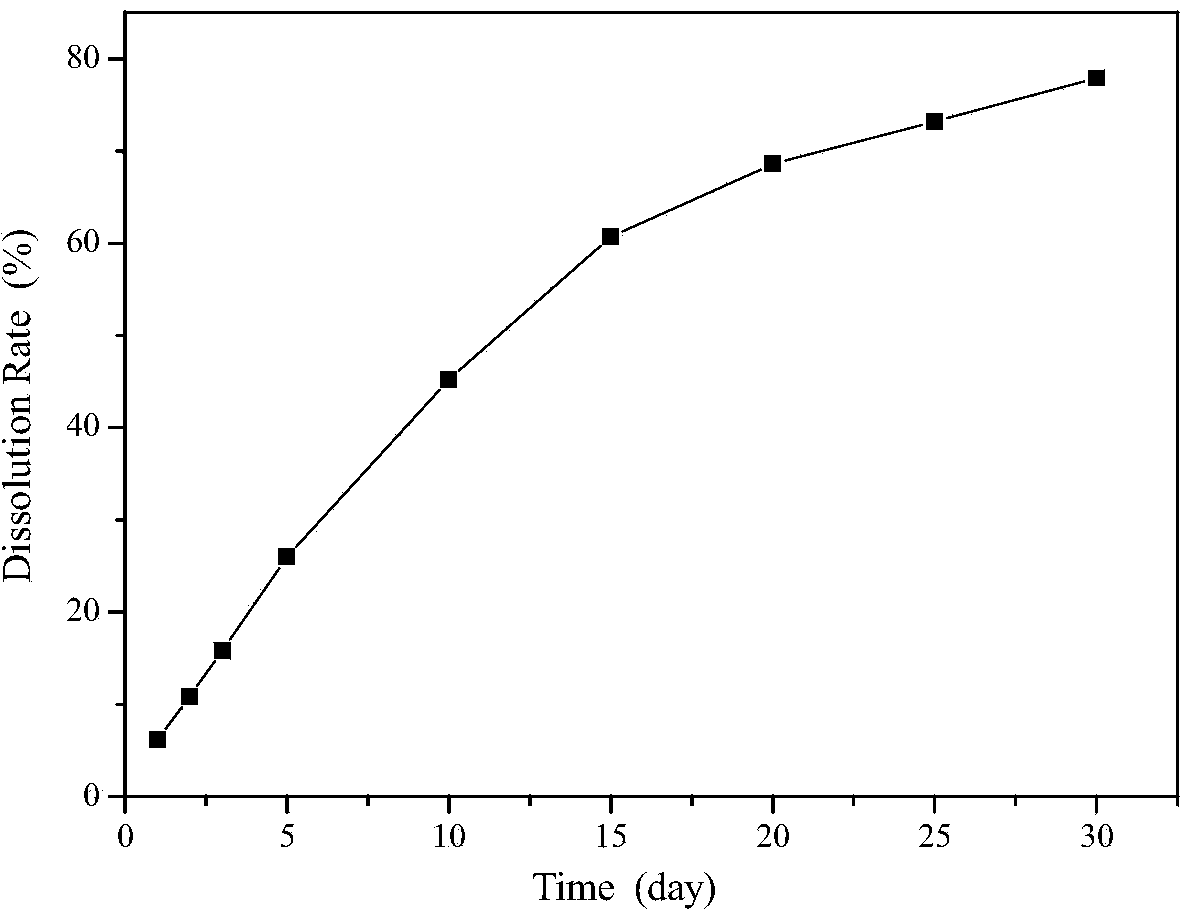

[0038] Put 90g of urea with uniform particle size into the sugar coating machine. After preheating for 5 minutes, start rolling granulation, spray 2mL of atomized 3% PVA / 0.8PVAc binder into it, and wait until the surface of urea granules forms a uniform layer. After adding 3.3g of diatomite powder, roll and granulate for about 5 minutes until the surface of the fertilizer granules forms a coating layer. Repeat the above process 3 times to finish adding 10g of diatomaceous earth, roll and granulate until the granules ar...

Embodiment 3

[0041] First put diatomaceous earth into drying oven and dry 12h at 150°C, after sieving through a 200-500 mesh standard sampling sieve, seal it for subsequent use;

[0042] Weigh different amounts of PVA, heat it to dissolve in water, then add a certain amount of PVAc, and after cooling, constant volume is configured to form a mixed binder. The mass percentage of PVA in the mixed binder solution is 4%, and the mass percentage of PVAc 1%, sealed for later use;

[0043] Put 90g of urea with uniform particle size into the sugar coating machine. After preheating for 5 minutes, start rolling granulation, spray 1.5mL of atomized 4%PVA / 1.0%PVAc binder into it, and wait until the surface of the urea granules forms a After layering a uniform binder, add 2.5g of diatomaceous earth powder, roll and granulate for about 6 minutes until the surface of the fertilizer granules forms a coating layer. Repeat the above process 4 times to finish adding 10g of diatomaceous earth, roll and granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com