High thermal conductivity and high voltage resistance power cable sleeve

A power cable and high-voltage-resistant technology, which is applied in the field of high-thermal-conduction and high-voltage-resistant power cable casings, can solve problems that affect the service life of power cables, reduce the current carrying capacity of power cables, and increase the temperature of power cables, and overcome the strength difference. , avoid the effect of temperature rise, toughness and heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The parts by weight are polyethylene: 85-95 parts, nano-scale copper powder: 3-15 parts, zinc oxide: 3-5 parts, polypropylene grafted maleic anhydride: 3-5 parts;

[0031] 2. Process the above mixed materials by extrusion, molding or injection;

[0032] 3. Cooling and molding the pipe obtained by the extrusion, molding or injection method to obtain a high thermal conductivity and high voltage resistant power cable sleeve.

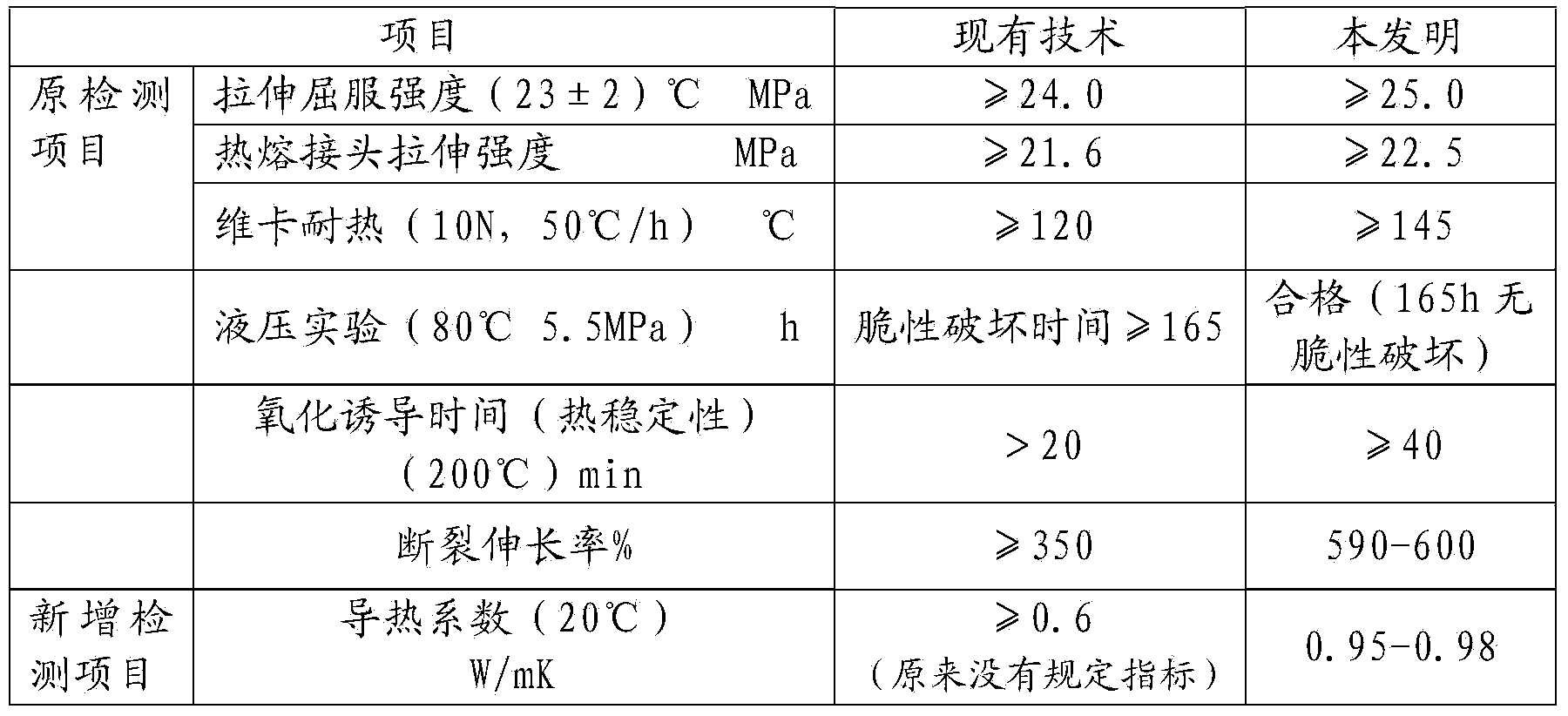

[0033] The main performance index of this embodiment is compared with existing standard as follows:

[0034]

Embodiment 2

[0036] 1. The parts by weight are polyethylene: 85-95 parts, nanoscale copper-aluminum mixed powder: 3-15 parts, mixture of barium carbonate, chromium carbonate and silicon dioxide: 3-5 parts, polypropylene grafted with Malay Anhydride: 3 to 5 parts mixed;

[0037] 2. Process the above mixed materials by extrusion, molding or injection;

[0038] 3. Cooling and molding the pipe obtained by the extrusion, molding or injection method to obtain a high thermal conductivity and high voltage resistant power cable sleeve.

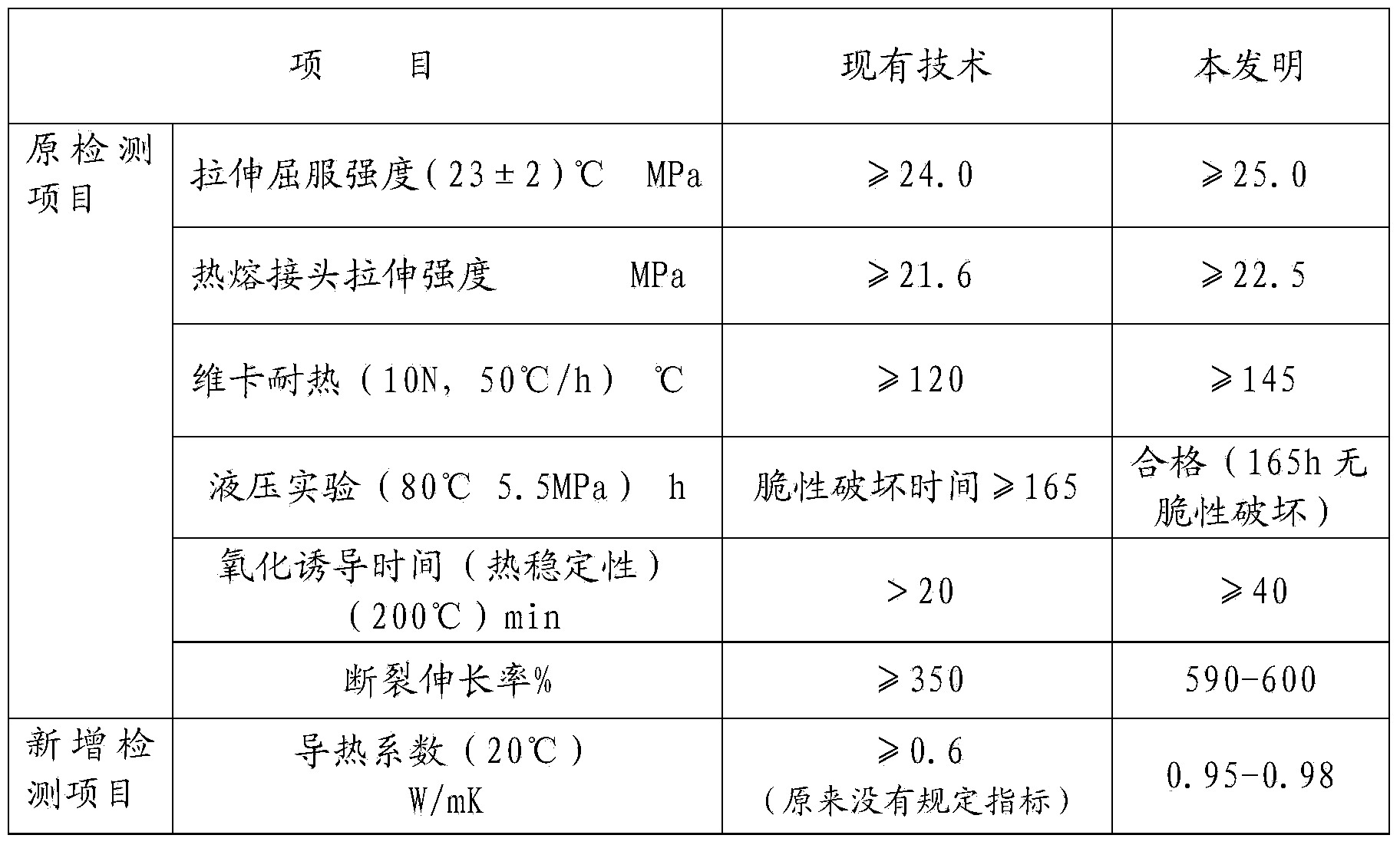

[0039] The main performance index of this embodiment is compared with existing standard as follows:

[0040]

Embodiment 3

[0042] 1. The parts by weight are polypropylene: 85-95 parts, nano-scale copper-iron mixed powder: 3-15 parts, montmorillonite: 3-5 parts, polypropylene grafted maleic anhydride: 3-5 parts;

[0043] 2. Process the above mixed materials by extrusion, molding or injection;

[0044] 3. Cooling and molding the pipe obtained by the extrusion, molding or injection method to obtain a high thermal conductivity and high voltage resistant power cable sleeve.

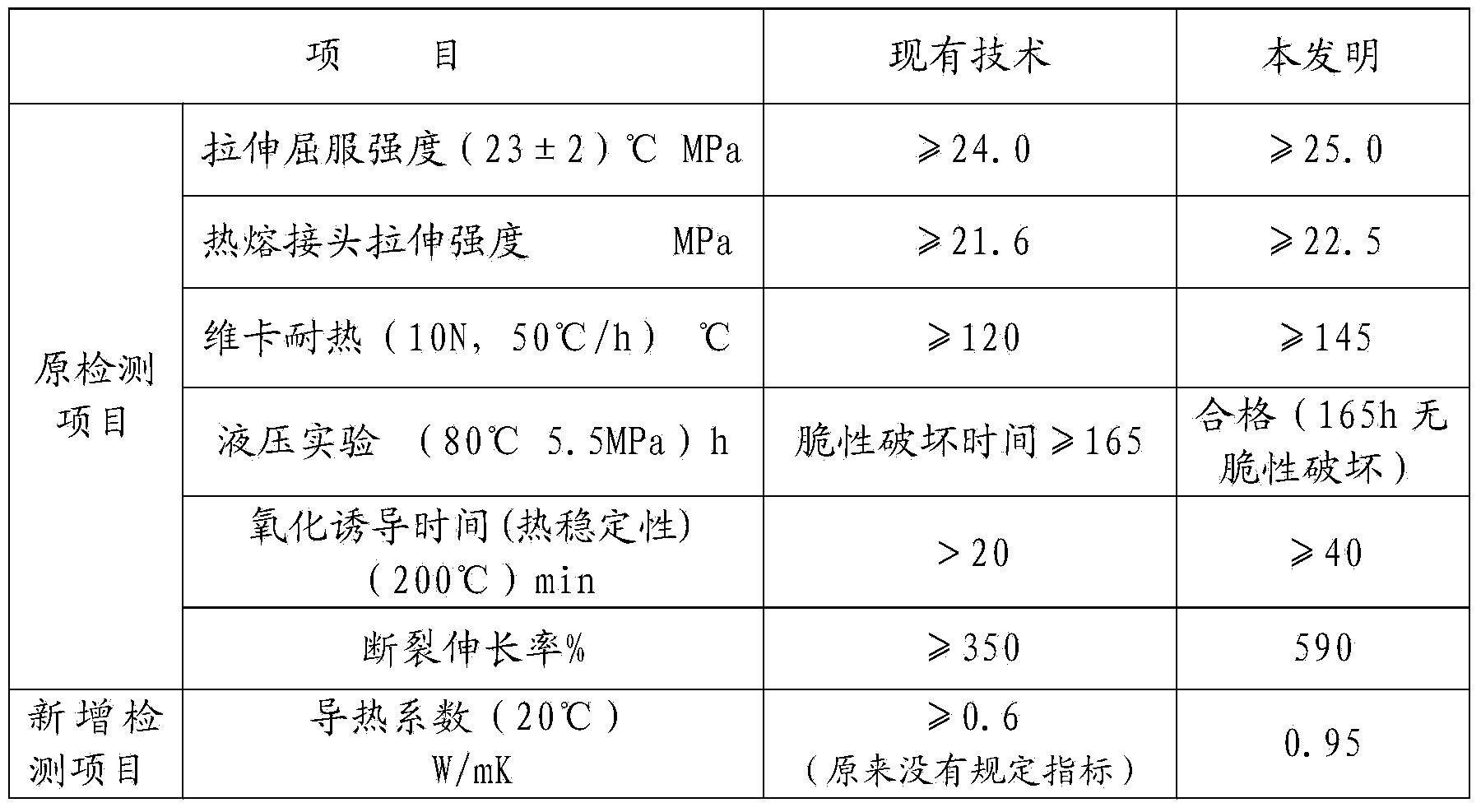

[0045] The main performance index of this embodiment is compared with existing standard as follows:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com