Method for constructing directly-buried heat-preservation pipeline passing by marshland section

A technology for thermal insulation pipelines and construction methods, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as long pipeline construction period, reduce leakage risk points, reduce maintenance costs, and reduce land use The effect of occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0053] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

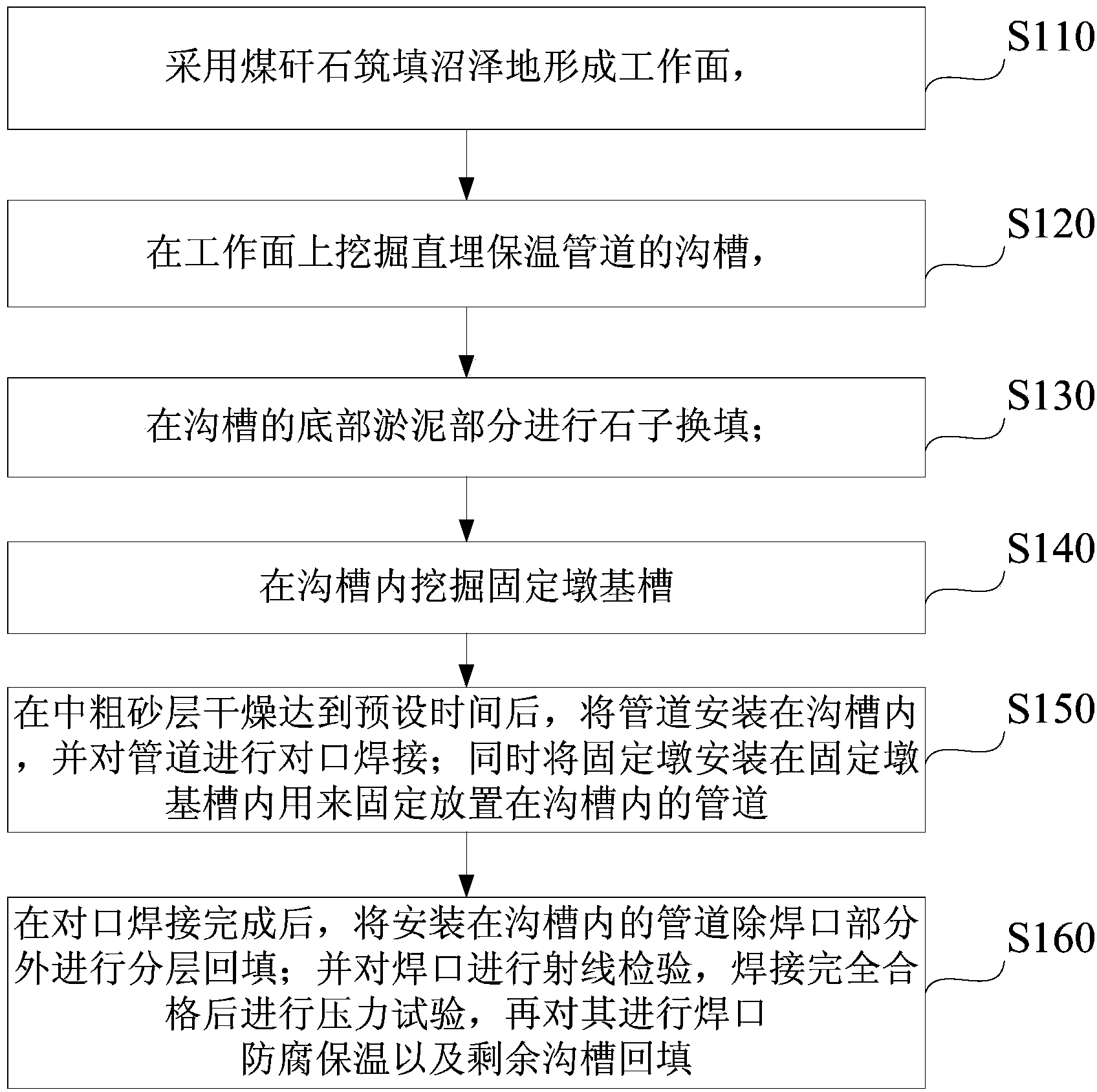

[0054] figure 1 It shows the construction method process of the directly buried thermal insulation pipeline passing through the swamp section according to the embodiment of the present invention; as figure 1 As shown, the construction method of the directly buried thermal insulation pipeline provided by the present invention passing through the swamp section includes: S110: Use coal gangue to build and fill the swamp to form a working face; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com