Formation method of semiconductor structure

A semiconductor and gate structure technology, applied in the field of semiconductor structure formation, can solve the problems of increasing the contact area between the gate structure and the fin, complex formation process, poor performance, etc., to suppress the short channel effect, increase the contact area, Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

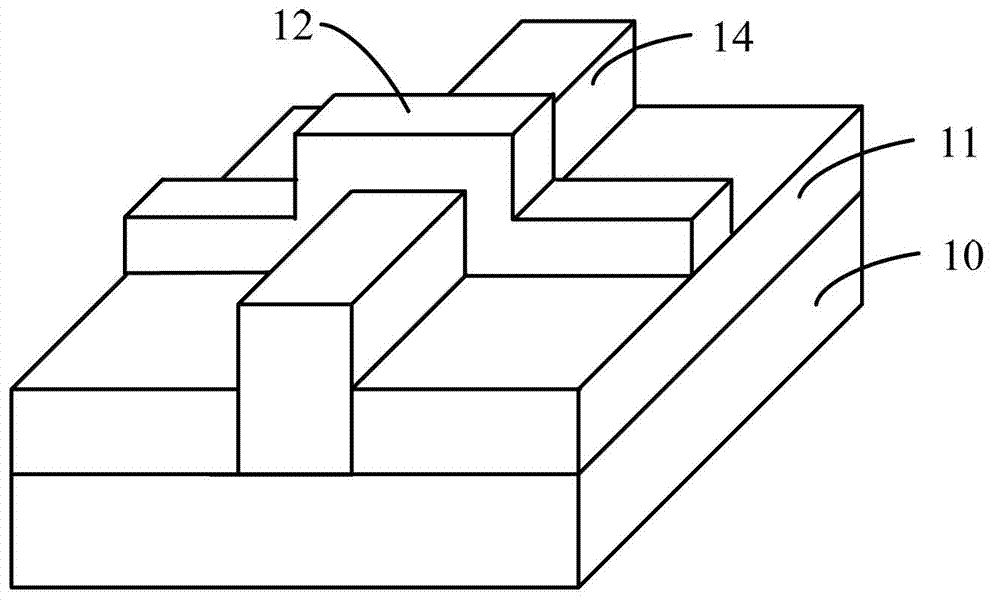

[0033] As mentioned in the background art, the formation process of the “Ω”-shaped fin field effect transistor in the prior art is complicated, which is not conducive to popularization.

[0034] specifically, Figure 2 to Figure 6 It is a schematic cross-sectional structure diagram of the formation process of an "Ω"-shaped fin field effect transistor in the prior art.

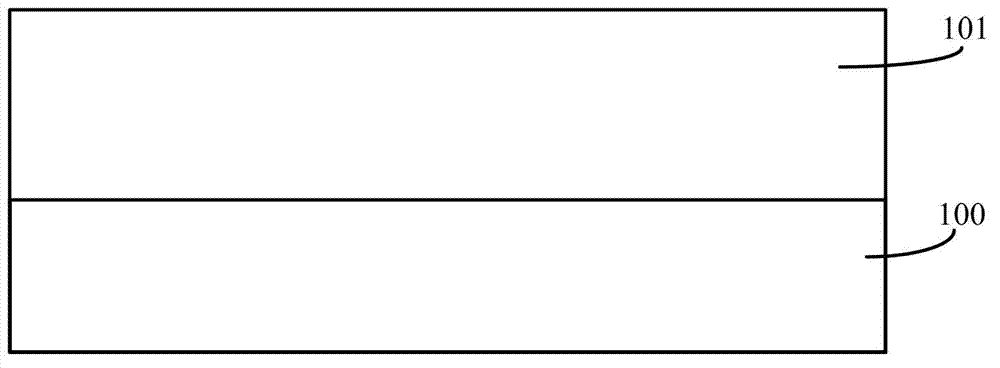

[0035] Please refer to figure 2 , providing a semiconductor substrate 100 with a fin layer 101 on the surface of the semiconductor substrate 100 .

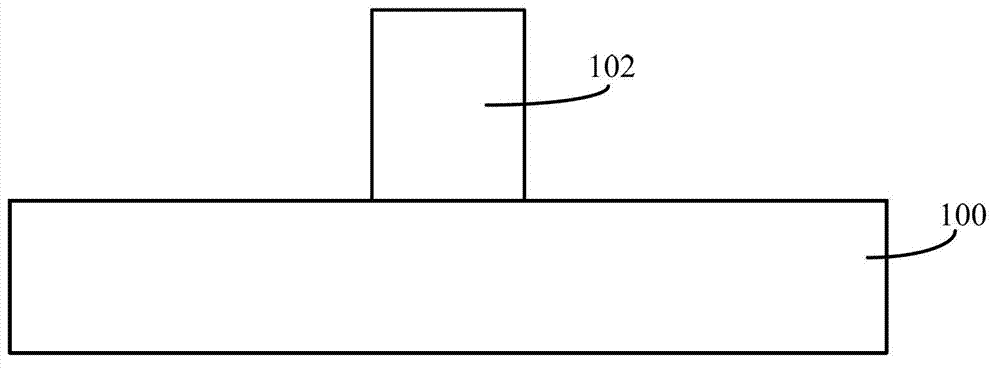

[0036] Please refer to image 3 , etch the fin layer 101 to form the fin 102 .

[0037] Please refer to Figure 4 , forming an insulating layer 103 covering part of sidewalls of the fins 102 on the surface of the semiconductor substrate 100 .

[0038] Please refer to Figure 5 A mask layer 104 is formed on the surface of the insulating layer 103 and the sidewall and top surface of the fin 102 .

[0039] Please refer to Figure 6 , remove the insulating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com