Preparation method of magnetic temperature-sensitive surface strontium ion blotting adsorbent

An imprinted adsorption and temperature-sensitive technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low adsorption capacity, poor rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

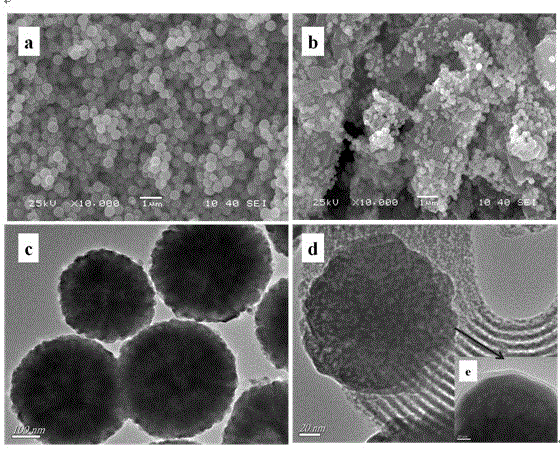

Image

Examples

Embodiment 1

[0041] (1) Magnetic core Fe 3 o 4 preparation of

[0042] Weigh 0.675 g FeCl 3 ·6H 2 O was dissolved in 40 mL of ethylene glycol and stirred until a yellow homogeneous solution formed. Add 3.6 g of anhydrous sodium acetate (NaOAc) and 1.0 g of polyethylene glycol (PEG10000) to the above solution in turn, continue to stir for 30 min, then quickly transfer it to a 50 mL polytetrafluoroethylene autoclave, 200 o C for 8 h, cooled to room temperature, washed with ethanol, 60 o C dried overnight.

[0043] (2) Synthesis of PEI-SBA-15

[0044] Weigh 5.00 g of SBA-15 and 7 mL of γ-chloropropyltrimethoxysilane (CP) in 40 mL of xylene solution, slowly drop into 1.4 mL of deionized water, 80 o The reaction was carried out under the condition of C for 6 h, and the excess CP was washed with toluene to obtain the surface chloropropylated SBA-15 (CP-SBA-15). The prepared CP-SBA-15 (5.00 g) was added to 25 mL of 20% polyethyleneimine (PEI) aqueous solution, 90 o The reaction w...

Embodiment 2

[0055] (1) Magnetic core Fe 3 o 4 preparation of

[0056] Weigh 1.35 g FeCl 3 ·6H 2 O was dissolved in 40 mL of ethylene glycol and stirred until a yellow homogeneous solution formed. Add 3.6 g of anhydrous sodium acetate (NaOAc) and 1.0 g of polyethylene glycol (PEG10000) to the above solution in turn, continue to stir for 30 min, then quickly transfer it to a 50 mL polytetrafluoroethylene autoclave, 200 o C for 10 h, cooled to room temperature, washed with ethanol, 60 o C dried overnight.

[0057] (2) Synthesis of PEI-SBA-15

[0058] Weigh 5.00 g of SBA-15 and 14 mL of γ-chloropropyltrimethoxysilane (CP) in 40 mL of xylene solution, slowly drop into 2.0 mL of deionized water, 80 o The reaction was carried out under the condition of C for 6 h, and the excess CP was washed with toluene to obtain the surface chloropropylated SBA-15 (CP-SBA-15). The prepared CP-SBA-15 (5.00 g) was added to 50 mL of 20% polyethyleneimine (PEI) aqueous solution, 90 o The reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com