Building block produced by using phosphogypsum, carbide slag and coal ash through carbonization and steam curing

A technology of building blocks and calcium carbide slag, which is applied in the field of building materials, can solve problems such as high alkali content, pollute the environment, block sewers, etc., and achieve the effect of high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

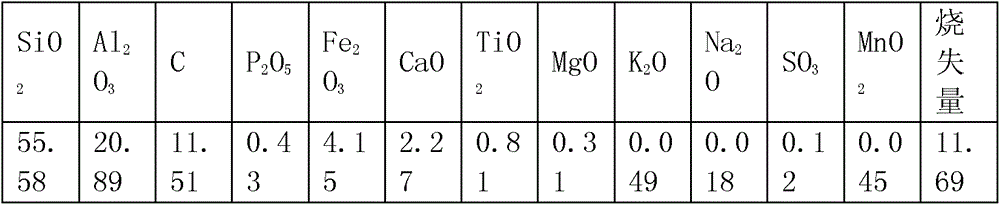

Method used

Image

Examples

Embodiment 1

[0055] Phosphogypsum, carbide slag, and fly ash are used to produce building blocks by carbonization and steam curing. Its formula and production steps are as follows:

[0056] Raw material formula

[0057] Phosphogypsum 30% Carbide slag 30% Fly ash 30%

[0058] Coarse sand 10% Pigment 0.1% Water Appropriate amount

[0059] steps:

[0060] 1. Preparation of materials: Grind phosphogypsum and fully mix it with 2-5% calcium carbide slag; at the same time, add water to adjust it to a wet state, and accumulate it for 10-48 hours, during which the pH value is maintained at 7-9.5;

[0061] 2. Mixed material Take 1 of the prepared material and mix it with other materials in proportion, add water during stirring to adjust to easy processing and molding to obtain the mixed material;

[0062] 3. Molding Put the 2 compound into the molding machine and mold it under the pressure of 15-50MPa to form the product blank;

[0063] 4. Carbonization The product blank is heated in the carboni...

Embodiment 2

[0068] Phosphogypsum, carbide slag, and fly ash are used to produce building blocks by carbonization and steam curing. Its formula and production steps are as follows:

[0069] Raw material formula

[0070] Phosphogypsum 30% Carbide slag 30% Fly ash 30%

[0071] Coarse sand 10% Additive 0 Water Proper amount

[0072] steps

[0073] 1. Preparation of materials: Grind phosphogypsum and fully mix it with 2-5% calcium carbide slag; at the same time, add water to adjust it to a wet state, and accumulate it for 10-48 hours, during which the pH value is maintained at 7-9.5;

[0074] 2. Mixed material Take 1 of the prepared material and mix it with other materials in proportion, add water during stirring to adjust to easy processing and molding to obtain the mixed material;

[0075] 3. Molding Put the 2 compound into the molding machine and mold it under the pressure of 15-50MPa to form the product blank;

[0076] 4. Carbonization The product blank is heated in the carbonization k...

Embodiment 3

[0081] Phosphogypsum, carbide slag, and fly ash are used to produce building blocks by carbonization and steam curing. Its formula and production steps are as follows:

[0082] Raw material formula

[0083] Phosphogypsum 40% Carbide slag 30% Fly ash 20%

[0084] Coarse sand 10% Additive 0 Water Proper amount

[0085] steps:

[0086] 1. Preparation of materials: Grind phosphogypsum and fully mix it with 2-5% calcium carbide slag; at the same time, add water to adjust it to a wet state, and accumulate it for 10-48 hours, during which the pH value is maintained at 7-9.5;

[0087] 2. Mixed material Take 1 of the prepared material and mix it with other materials in proportion, add water during stirring to adjust to easy processing and molding to obtain the mixed material;

[0088] 3. Molding Put the 2 compound into the molding machine and mold it under the pressure of 15-50MPa to form the product blank;

[0089] 4. Carbonization The product blank is heated in the carbonization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com