Preparation method of catalyst containing imidazole and derivatives thereof

A derivative and catalyst technology, applied in the field of catalyst preparation, can solve the problems of poor catalyst performance and less research, and achieve the effects of uniform distribution, good conductivity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

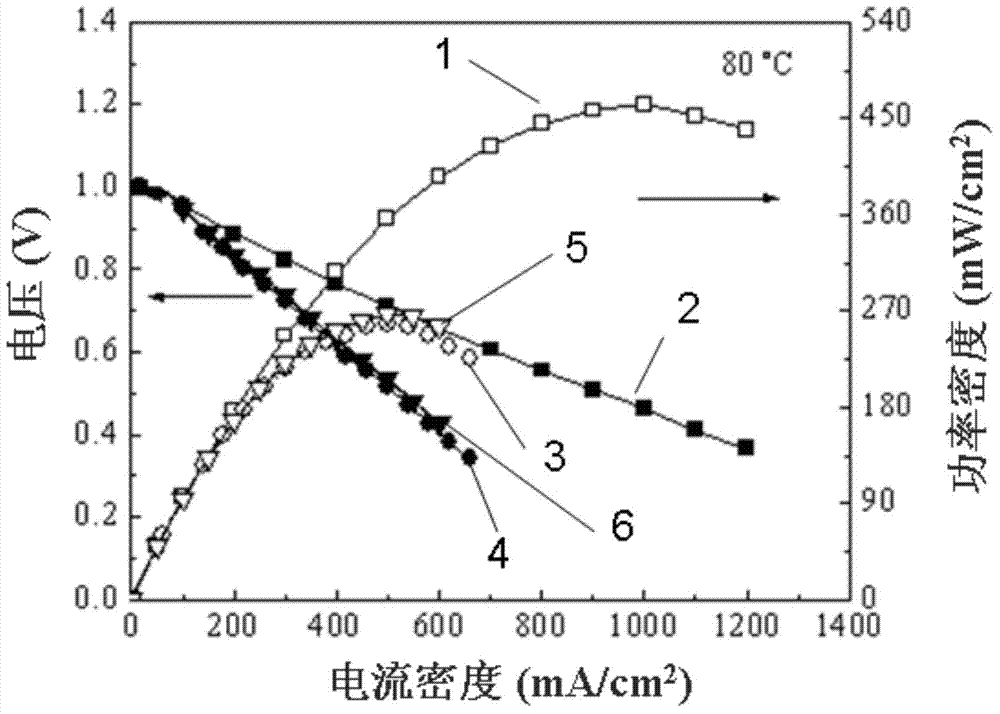

Image

Examples

preparation example Construction

[0027] The preparation method of the catalyst containing imidazole and its derivatives is used to prepare imidazole and its derivatives modified nitrogen-containing macroporous carbon-loaded transition metal catalyst, comprising the following steps:

[0028] Step A: Take hydrophilic nano-CaCO with a particle size of 15-40nm 3 , urea, and glucose were added to deionized water, and the hydrophilic nano-CaCO 3 , The mass ratio of urea, glucose and deionized water is 8:8:8:100, and then ultrasonically vibrate and mix for 30 minutes to dissolve urea and glucose and mix with nano-CaCO 3 Uniformly dispersed, cured at 106°C for 6 hours to form a cured product, the cured product was heated to 500°C under the protection of a nitrogen atmosphere, carbonized at a constant temperature for 2 hours, and then carbonized at a constant temperature of 900°C for 2 hours to form a carbonized product, and the cured product was formed at 80°C The carbonized product was washed successively with 5wt%...

Embodiment 1

[0032] Example 1: Preparation of macroporous carbon

[0033] Hydrophilic nano-CaCO with a particle size of 15-40nm 3 Add 8g each of urea and glucose to 100mL deionized water, and mix with ultrasonic vibration for 30 minutes to dissolve urea and glucose and mix with nano-CaCO 3 Disperse evenly; then cure at 106°C for 6 hours; heat the cured product to 500°C under the protection of a nitrogen atmosphere, and carbonize at a constant temperature for 2 hours; then carbonize at a constant temperature for 2 hours at 900°C; concentration of hydrochloric acid, 30wt% concentration of sodium hydroxide solution, deionized water washing, constant temperature drying at 120 ° C for 4 hours, to obtain nitrogen-containing macroporous carbon materials.

Embodiment 2

[0034] Example 2: Preparation of imidazole-modified macroporous carbon-supported noble metal catalyst

[0035] Hydrophilic nano-CaCO with a particle size of 15-40nm 3 Add 8g each of urea and glucose to 100mL deionized water, and mix with ultrasonic vibration for 30 minutes to dissolve urea and glucose and mix with nano-CaCO 3 Disperse evenly; then cure at 106°C for 6 hours; heat the cured product to 500°C under the protection of a nitrogen atmosphere, and carbonize at a constant temperature for 2 hours; then carbonize at a constant temperature for 2 hours at 900°C; Hydrochloric acid, 30wt% sodium hydroxide solution, deionized water washing, constant temperature drying at 120 ° C for 4 hours, to obtain nitrogen-containing macroporous carbon materials.

[0036] Crush the nitrogen-containing macroporous carbon material to a particle size of 100-400 mesh, take 2g of nitrogen-containing macroporous carbon and place it in a hydrothermal reaction kettle with a volume of 150mL, add 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com