Dry-and-wet neutral detergent fiber (NDF) macromolecular self-adhesive waterproof coiled material, as well as production process and equipment thereof

A self-adhesive waterproof membrane, wet and dry technology, applied in the direction of layered products, building insulation materials, asphalt layered products, etc. Wide range, smooth surface, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A wet and dry dual-purpose NDF polymer self-adhesive waterproof membrane, prepared from the following raw materials in parts by weight:

[0026] 20 parts of 10# asphalt, 50 parts of 100# asphalt, 6 parts of thermoplastic styrene-butadiene rubber, 6 parts of styrene-butadiene rubber, 5 parts of softener, 3 parts of curing agent, 4 parts of reactant, 3.5 parts of thickener, 2.5 parts of C9 resin .

[0027] Wherein, described 10# bitumen is the bitumen that penetration is at 10; Described 100# bitumen is the bitumen that penetration is at 100;

[0028] The thermoplastic styrene-butadiene rubber (SBS), also known as styrene-butadiene thermoplastic elastomer, is a new type of synthetic elastomer that has the properties of both plastic and rubber. Low temperature resistance, air permeability and wet skid resistance, easy to process and shape, simple process during processing, no need for vulcanization, low energy consumption, easy to color;

[0029] Styrene butadiene rubber...

Embodiment 2

[0033] A kind of production process of wet and dry dual-purpose NDF type macromolecule self-adhesive waterproof roll material described in embodiment 1, described process comprises the following steps:

[0034](1) Ingredients mixing: Melt 10# asphalt and 100# asphalt in various containers through a heat transfer oil boiler. The temperature of the heat transfer oil boiler is controlled at 250±5°C. The above mass ratio is transported to the oxidation tank, and SBS is added at the same time to continue stirring, and then styrene-butadiene rubber, softener, curing agent, reactant, and C9 resin are added in sequence, and the temperature is raised to 200±5°C for oxidation, and the colloid mill is started. Grind while stirring, grind 2-3 times and stir until uniform, add talcum powder (ie thickener), and then transport it to the tire loading device through the oil guide pump for tire loading, and the temperature during the oil guide pump delivery is controlled at 140±5°C;

[0035] (2...

Embodiment 3

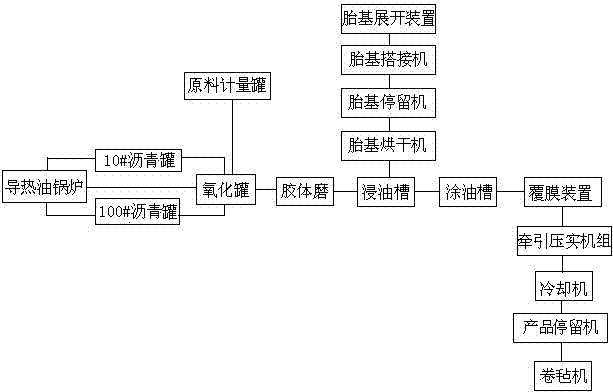

[0041] A kind of equipment that is used for the wet and dry dual-purpose NDF type polymer self-adhesive waterproof roll material production process described in embodiment 2, comprises 10# asphalt tank and 100# asphalt tank, described 10# asphalt tank and 100# asphalt tank All are connected with the oxidation tank, the 10# asphalt tank, the 100# asphalt tank and the oxidation tank are all connected with the heat conduction oil boiler, and the oxidation tank is also connected with the raw material metering tank, and the raw material metering tank is equipped with a plurality of There are C9 resin, talcum powder, styrene-butadiene rubber, softener, curing agent, reactant, thickener and other raw materials. The oxidation tank is connected with colloid mill, oil immersion tank and oil coating tank in sequence. The oil immersion tank is equipped with oil immersion The oiling groove is provided with an oiling roller, and the inlet end of the oiling roller is also provided with a tire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com