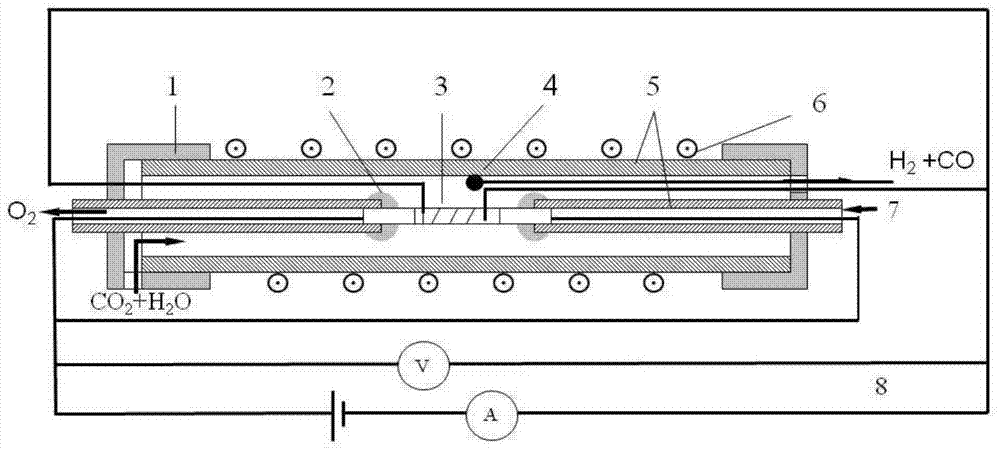

Technique for preparing synthetic gas from wet carbon dioxide by electrocatalysis

A technology of carbon dioxide and electrocatalysis, applied in the chemical industry, sustainable manufacturing/processing, hydrogen production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

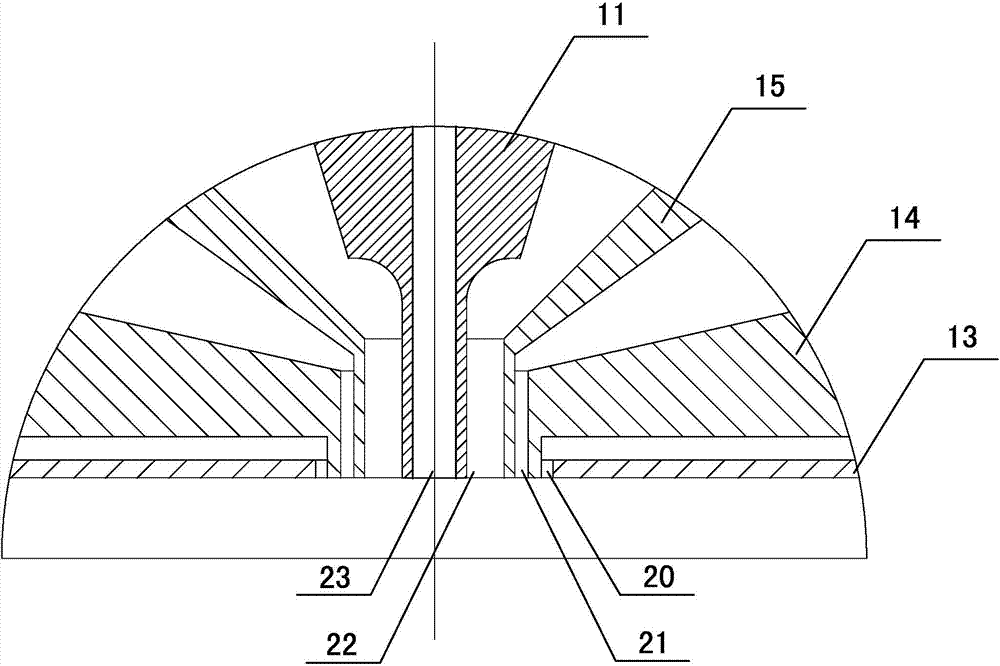

[0057] The four-ring hole spinning die adopted in Example 1 has a four-ring hole structure. From the inside to the outside, the diameter of the inner gel bath channel is 2mm, the diameter of the inner layer channel is 3mm, the diameter of the middle layer channel is 4mm, and the diameter of the outer layer channel 5mm;

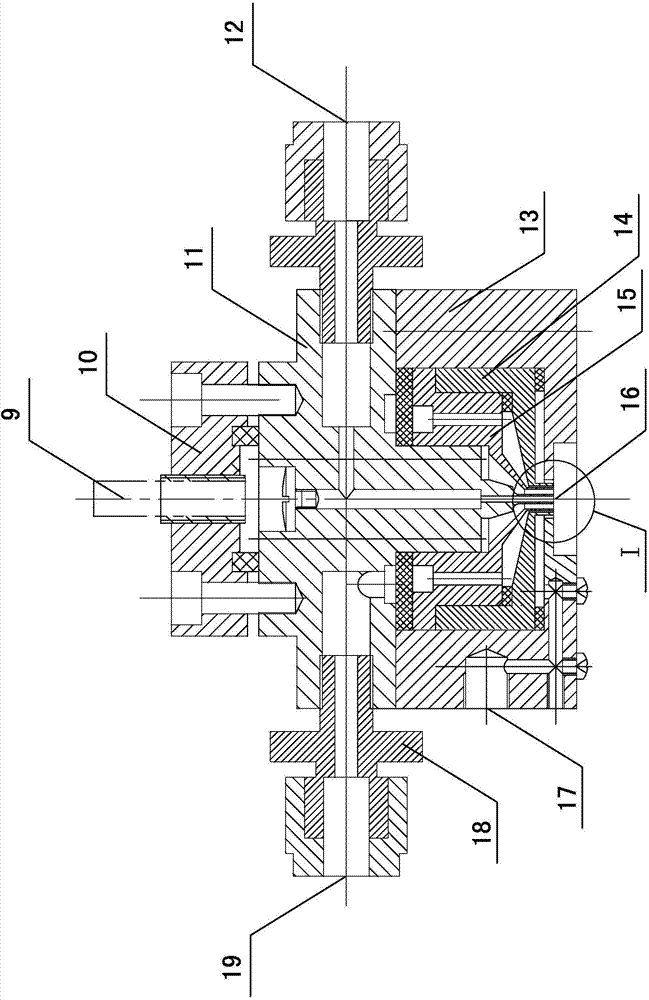

[0058] like Figure 2-3 As shown, the four-ring hole spinning die for co-spinning includes a bottom cover 13, an upper spacer 11, a middle spacer 15, and a lower spacer 14, wherein an outlet 16 is provided at the bottom of the bottom cover 13, and the bottom cover The inside of 13 is successively the lower spacer 14, the middle spacer 15, and the upper spacer 11; the upper part of the upper spacer 11 is provided with a spacer cover 10, and the spacer cover 10 is provided with an inner material hole 9 connected with the upper spacer 11, The middle layer material hole 19 and the inner gel bath material hole 12 are respectively set on the two side walls of the u...

Embodiment 2

[0081] The structure of the four-ring hole spinning die adopted in embodiment 2 is as in embodiment 1, and the difference is that, from the inside to the outside, the diameter of the inner gel bath channel is 2mm, the diameter of the inner layer channel is 2.8mm, and the diameter of the middle layer channel is 2mm. 3.5mm, the outer channel diameter is 4.2mm;

[0082] The preparation method of the microtubular electrocatalytic membrane reactor of embodiment 2 comprises the following steps:

[0083] (1) Metal-ceramic collector layer ceramic materials, cathode functional layer ceramic materials and dense electrolyte layer ceramic materials:

[0084] Dense electrolyte layer ceramic material: Electrolyte powder is used, which is composed of nano-powder GDC (20-30nm) and micro-powder GDC (1-50μm), and the mass ratio of nano-powder to micro-powder is 8 / 2;

[0085] Cermet current-collecting layer ceramic material: nickel oxide and electrolyte (micron powder GDC1-50μm) are mixed and b...

Embodiment 3

[0099] The structure of the four-ring hole spinning die adopted in Example 3 is as in Example 1.

[0100] The preparation method of the microtubular electrocatalytic membrane reactor of embodiment 3 comprises the following steps:

[0101] (1) Metal-ceramic collector layer ceramic materials, cathode functional layer ceramic materials and dense electrolyte layer ceramic materials:

[0102] Dense electrolyte layer ceramic material: Electrolyte powder is used, which is composed of nano-powder YSZ (20-30nm) and micro-powder YSZ (1-50μm), the mass ratio of nano-powder to micro-powder is 8 / 2;

[0103] Cermet current-collecting layer ceramic material: nickel oxide and electrolyte (micron powder YSZ1-50μm) are mixed and ball milled, and the mass ratio of nickel oxide and electrolyte is 8 / 2;

[0104] Cathode functional layer ceramic material: Nickel oxide and electrolyte (micron powder YSZ1-50μm) are mixed and ball milled, and the mass ratio of nickel oxide and electrolyte is 5 / 5.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com