Device and method for purifying, deoxidizing and decarbonizing internal generator cooling water

A technology of cooling water and oxygen decarbonization, applied in the fields of chemistry, environmental technology and energy, which can solve problems such as difficult regeneration operations and lack of adjustable functions, and achieve effective reuse, avoid improper disposal, and reduce content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The specific steps of a method for purifying cooling water in a generator and removing oxygen and decarburization are as follows:

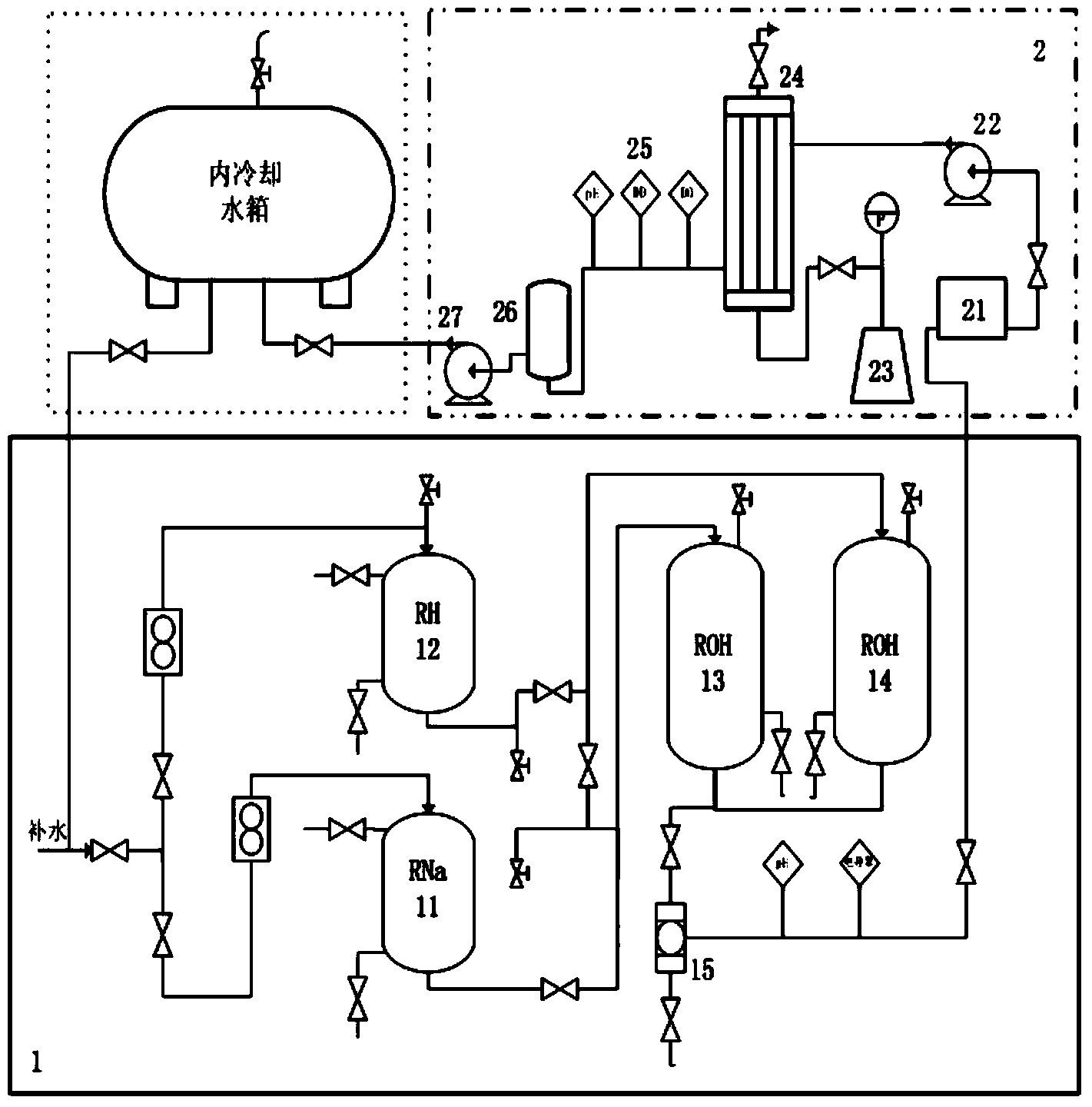

[0052] The inner cooling water first enters the independent RNa type cation exchange tower and RH type cation exchange tower to exchange copper ions in the inner cooling water. After the internal cooling water treated by the RNa type cation exchange tower is adjusted by the flow monitoring and adjusting device, it enters the first ROH type anion exchange tower; after the internal cooling water treated by the RH type cation exchange tower is adjusted by the flow monitoring and adjusting device, it enters The second ROH type anion exchange tower; the effluents of the two sets of ROH type anion exchange towers are confluenced so that the copper ion content in the inner cooling water is ≤20μg / L and the conductivity is 0.4~2.0μS / cm (25°C); The final internal cooling water uses PVDF hollow fiber separation membrane module to deoxygenate and decar...

Embodiment 2

[0054] The specific steps of a method for purifying cooling water in a generator and removing oxygen and decarburization are as follows:

[0055] The inner cooling water first enters the independent RNa type cation exchange tower and RH type cation exchange tower to exchange copper ions in the inner cooling water. After the internal cooling water treated by the RNa type cation exchange tower is adjusted by the flow monitoring and adjusting device, it enters the first ROH type anion exchange tower; after the internal cooling water treated by the RH type cation exchange tower is adjusted by the flow monitoring and adjusting device, it enters The second ROH type anion exchange tower; the effluents of the two sets of ROH type anion exchange towers are confluenced so that the copper ion content in the inner cooling water is ≤15μg / L, and the conductivity is ≤0.8μS / cm (25°C); and then the adjusted The inner cooling water adopts inorganic ceramic separation membrane module to deoxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com