TiC-reinforced cobalt-based metal ceramic composite coating on titanium alloy surface and preparation process thereof

A technology of ceramic compounding and preparation technology, which is applied in the direction of metal material coating technology and coating, and can solve the problem of less cobalt-based alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

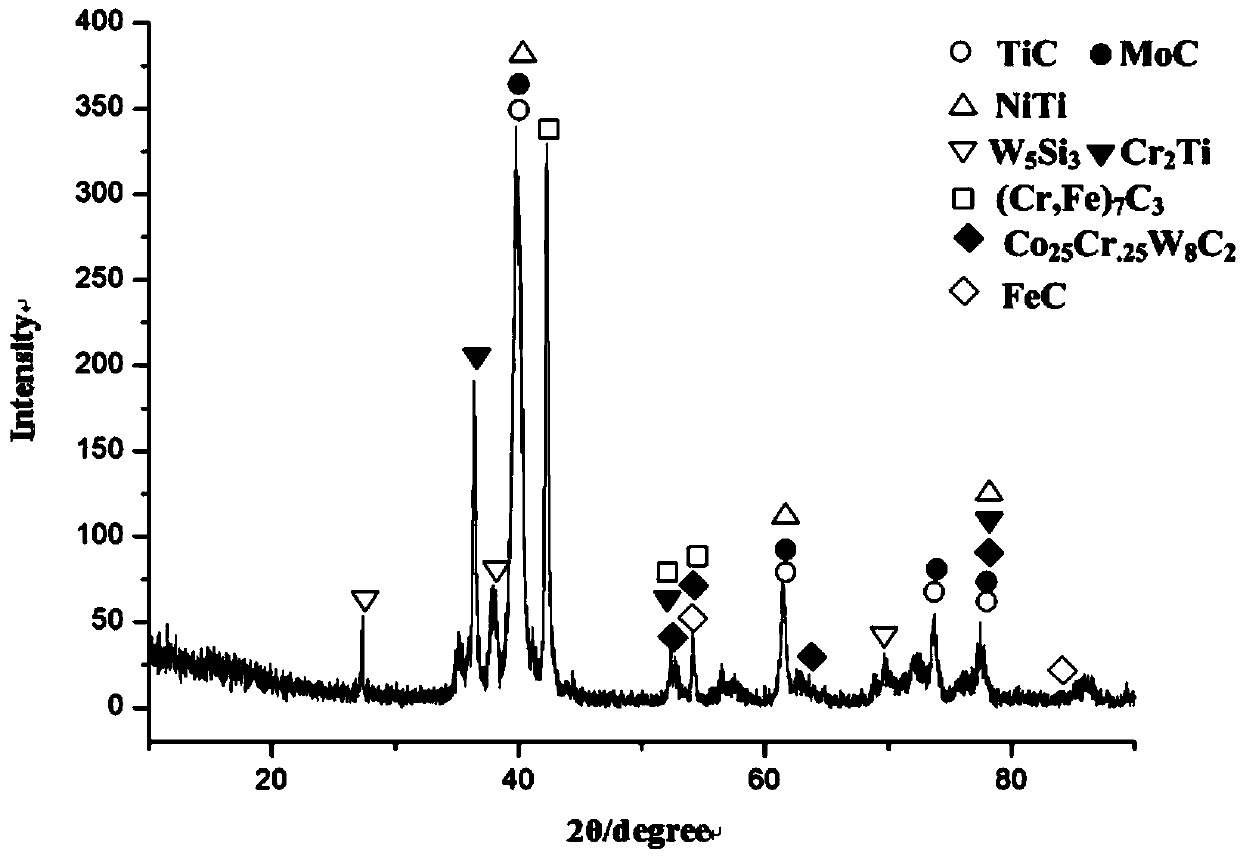

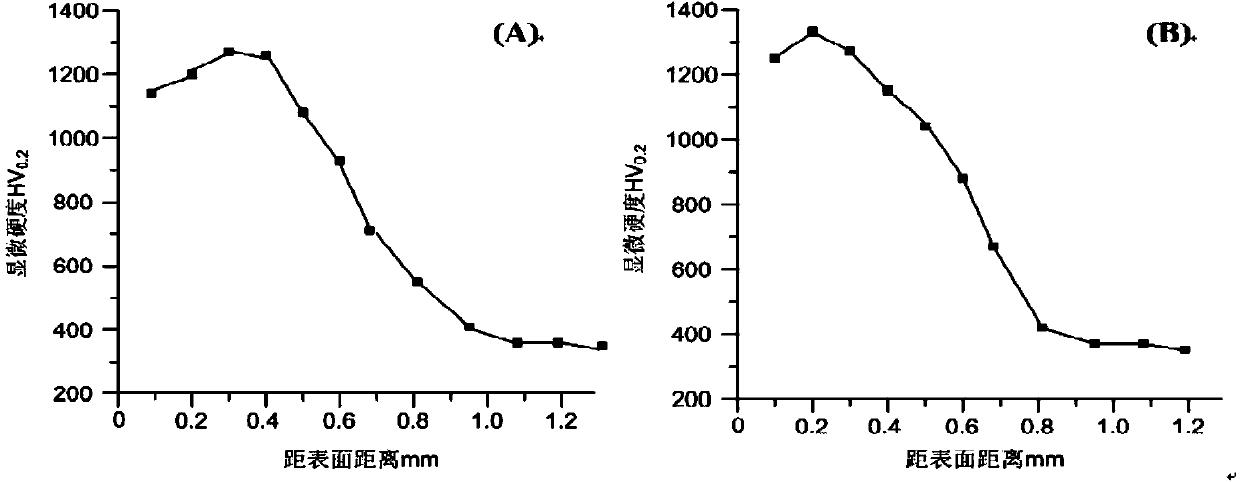

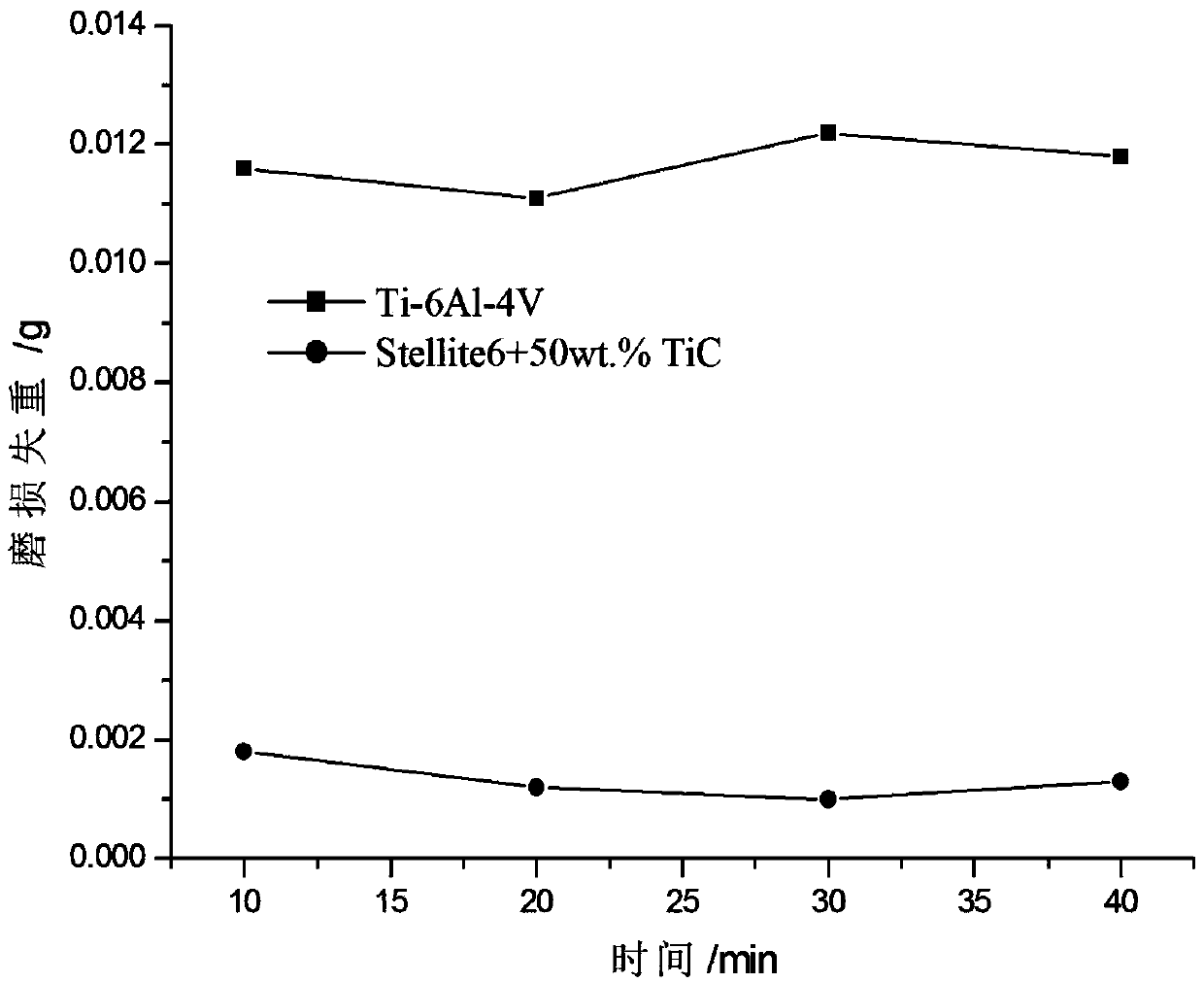

[0039] A TiC-enhanced cobalt-based cermet composite coating on the surface of a titanium alloy is prepared by using a mixture of cobalt-based alloy and TiC as a cladding material and using laser cladding technology. The specific steps are as follows:

[0040] (1) Clean the surface of the titanium alloy sample, clean it after wire electric discharge cutting, and dry it for later use;

[0041] (2) Weigh the cladding material powder according to a certain mass ratio, and mix the powder evenly;

[0042] (3) Adjust the mixed powder of the cladding material into a paste with a binder, and then evenly coat the surface of the titanium alloy substrate, the thickness is controlled at 0.7mm, and the thickness is kept uniform, and it is naturally air-dried;

[0043] (4) Laser cladding is carried out on the above-mentioned dried samples, the laser power is selected as 900W, the laser scanning speed is 2.5mm / s, the argon gas is blown for protection, the protection pressure is 0.2MPa, and th...

Embodiment 2

[0046] A TiC-enhanced cobalt-based cermet composite coating on the surface of a titanium alloy is prepared by using a mixture of cobalt-based alloy and TiC as a cladding material and using laser cladding technology. The specific steps are as follows:

[0047] (1) Clean the surface of the titanium alloy sample, clean it after wire electric discharge cutting, and dry it for later use;

[0048] (2) Weigh the cladding material powder according to a certain mass ratio, and mix the powder evenly;

[0049] (3) Adjust the mixed powder of the cladding material into a paste with a binder, and then evenly coat the surface of the titanium alloy substrate, the thickness is controlled at 0.7mm, and the thickness is kept uniform, and it is naturally air-dried;

[0050] (4) Laser cladding is carried out on the above-mentioned dried samples, the laser power is selected as 850W, the scanning speed of the laser is 2.5mm / s, the argon gas is blown for protection, the protection pressure is 0.2MPa,...

Embodiment 3

[0055] A TiC-enhanced cobalt-based cermet composite coating on the surface of a titanium alloy is prepared by using a mixture of cobalt-based alloy and TiC as a cladding material and using laser cladding technology. The specific steps are as follows:

[0056] (1) Clean the surface of the titanium alloy sample, clean it after wire electric discharge cutting, and dry it for later use;

[0057] (2) Weigh the cladding material powder according to a certain mass ratio, and mix the powder evenly;

[0058] (3) Adjust the mixed powder of the cladding material into a paste with a binder, and then evenly coat the surface of the titanium alloy substrate, the thickness is controlled at 0.7mm, and the thickness is kept uniform, and it is naturally air-dried;

[0059] (4) Laser cladding is carried out on the above-mentioned dried samples, the laser power is selected as 1000W, the scanning speed of the laser is 5mm / s, the argon gas is blown for protection, the protection pressure is 0.3MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com