Lead-acid battery and manufacturing method of negative plate thereof

A technology of lead-acid battery and negative plate, which is applied in the direction of lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., and can solve problems such as inability to perform high-current rapid charge and discharge, negative electrode capacity decline, and large impact on battery plates and negative plates. , to achieve the effect of promoting development and application, delaying the process of accumulation, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

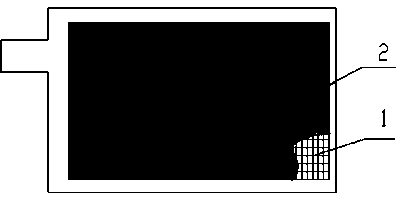

[0040] Embodiment 1 is a basic embodiment of a lead-acid storage battery of the present invention. A lead-acid battery, comprising a negative plate, the negative plate is composed of a negative grid 1 and an active material layer 2 solidified on the negative grid; the active material layer 2 is prepared by uniformly mixing carbon paste and lead paste together to form a negative wet paste, and then apply the negative electrode wet paste on the negative electrode grid 1, and finally solidify and dry; the composition of the carbon paste includes modified activated carbon, conductive agent, and SBR; the composition of the lead paste is The material includes lead powder and additives; lead paste or / and carbon paste are also mixed with a binder for improving the bonding performance between the components; the negative electrode wet paste is mixed with a certain amount of carbon paste and lead paste Add dilute sulfuric acid solution and lead-acid battery water to mix to form a slurry...

Embodiment 2

[0041] Embodiment 2, different from Example 1, the weight ratio of its charcoal paste and lead plaster of described negative electrode wet paste is 1: 10~200; The dilute sulfuric acid solution concentration that adds when charcoal paste mixes with lead plaster is 1~2g / ml; the adjusted viscosity of negative electrode wet paste is 3.5~5.5g / cm 3 .

Embodiment 3

[0042] Embodiment 3, different from Embodiment 1, the weight ratio of the carbon paste to the lead paste of the negative electrode wet paste is 1:200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com