Okra bean curd and preparation method thereof

A technology for okra and okra juice, which is applied in the field of okra tofu preparation, can solve the problems of slippery, sticky, bad taste, etc., and achieves the effects of smooth taste, protection of gastric mucosa, and improvement of structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of okra tofu, comprising the following steps:

[0026] 1) Prepare soy milk and okra juice separately;

[0027] The preparation process of the soymilk is as follows: the soybeans are made into raw soymilk after material selection, cleaning, soaking and grinding, and then the raw soymilk is boiled and filtered, wherein the water during grinding is 5% of the dry bean quality. times;

[0028] The preparation process of the okra juice is as follows: cleaning the harvested fresh and tender okra, selecting and removing impurities, cutting into sections, beating, and filtering, to prepare okra juice, and sterilizing the okra juice at high temperature instantaneously;

[0029] 2) Mixing: Mix the soy milk and okra juice in a mass ratio of 10:1 to form a mixed slurry;

[0030] 3) Sizing: adding D-gluconic acid-delta-lactone to the mixed slurry for spotting, and the mass ratio of the D-gluconic acid-delta-lactone to the mixed slurry is 0.001:1.

[0031] 4)...

Embodiment 2

[0035] Embodiment 2: readjust the mass ratio of soybean milk and okra juice, the mass ratio of D-gluconic acid-delta-lactone and mixed slurry, and correspondingly modify the corresponding mass ratio parameters in the preparation method of okra tofu, and the rest are the same as in Example 1 .

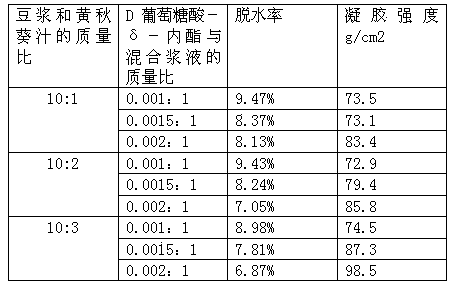

[0036] Among them, the newly adjusted mass ratio of soybean milk and okra juice, and the mass ratio of D-glucono-delta-lactone to mixed slurry are as follows:

[0037] (1) the mass ratio of described soybean milk and okra juice is 10:1, and the mass ratio of described D-glucono-delta-lactone and mixed slurry is 0.0015:1;

[0038] (2) the mass ratio of the soybean milk to the okra juice is 10:1, and the mass ratio of the D-glucono-δ-lactone to the mixed slurry is 0.002:1;

[0039] (3) the mass ratio of the soybean milk to the okra juice is 10:2, and the mass ratio of the D-glucono-δ-lactone to the mixed slurry is 0.001:1;

[0040] (4) the mass ratio of described soybean milk and okra j...

Embodiment 3

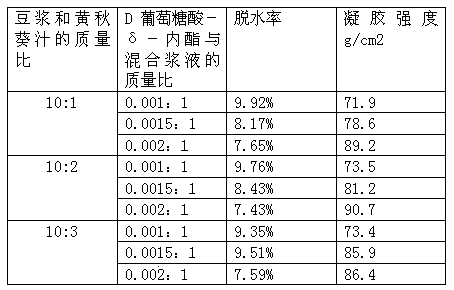

[0050]Adjust the mass ratio of dry beans to water to 1:6, and then re-adjust the mass ratio of soy milk and okra juice, and the mass ratio of D-glucono-δ-lactone to mixed slurry when ordering. The specific parameters are shown in Table 2 below:

[0051] Table 2: Dehydration rate and gel strength of okra tofu when the mass ratio of dry beans to water is 1:6

[0052]

[0053] In this embodiment, the mass ratio of dry beans and water is fixed at 1:6, the mass ratios of soy milk and okra juice are 10:1, 10:2 and 10:3 respectively, and the D-glucono-delta-lactone and mixed slurry The mass ratios are 0.001:1, 0.0015:1, and 0.002:1, respectively, and are combined into nine ratios, respectively, to obtain experimental data. The experimental procedure refers to "a preparation method of okra tofu" in Example 1, and each mass ratio parameter is adjusted accordingly.

[0054] In the same way, we ensure that the mass ratio of dry beans to water is 1:6 during grinding, and no okra juice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com