Patents

Literature

50 results about "D-gluconic acid" patented technology

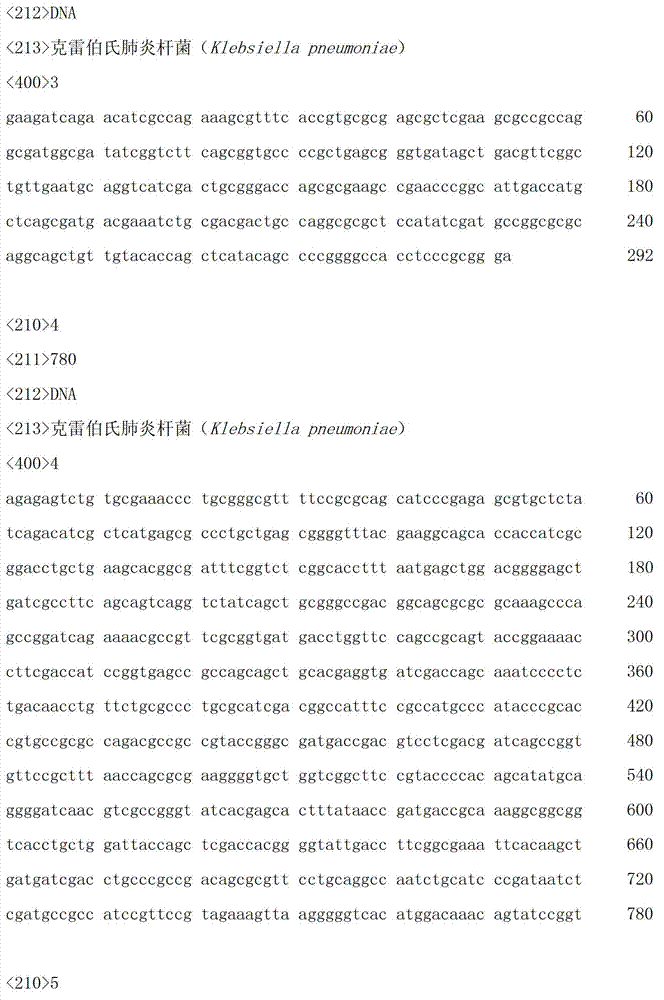

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

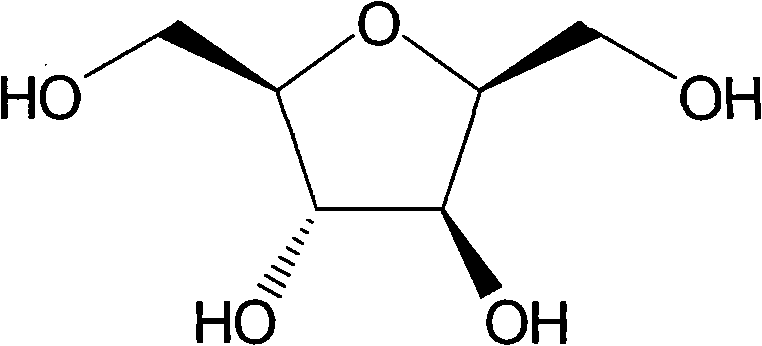

Gluconic acid is a polyhydroxycarboxylic acid with six carbon length. It is derived from glucose by oxidation of the aldehyde group on the C-1 to a carboxyl group. It is abundant in plants, fruits and other foodstuffs. Commercially the physiological d-form gluconic acid is prepared by fermentation process.

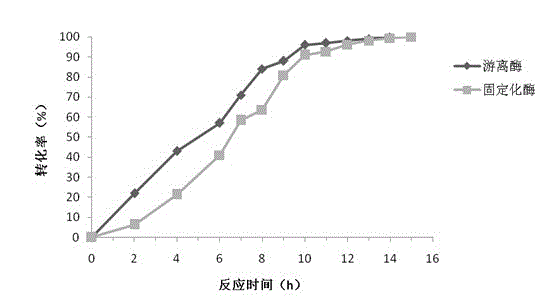

Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

InactiveCN102943069AFacilitates covalent attachmentExtended service lifeChemical industryOn/in organic carrierMicrosphereCatalytic oxidation

The invention discloses co-immobilization glucose oxidase / catalase microspheres and application thereof in preparation of gluconic acid (salt) for catalytic oxidation of glucose. The co-immobilization glucose oxidase / the catalase microspheres can effectively promote covalent linkage of carriers and enzyme molecules, immobilization efficiency is improved greatly, service life of immobilization glucose oxidase (GOD) / catalase (CAT) is prolonged remarkably, the co-immobilization glucose oxidase / the catalase microspheres can be used repeatedly, are low in production cost, and facilitate sustainable development. Gluconic acid (salt) prepared by the co-immobilization glucose oxidase / the catalase microspheres is high in yield, reaction condition is temperate, a device is simple and easy to obtain, and the production method is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

A serratia marcescens strain producing high-purity 2-keto-D-gluconic acid

The invention discloses a serratia marcescens strain producing high-purity 2-keto-D-gluconic acid, and belongs to the field of microorganisms. The strain is a serratia marcescens SDSPY-136 strain, is deposited in the China General Microbiological Culture Collection Center in February 9, 2015, and has an accession number of CGMCC No:10548. The strain can adopts glucose and trehalose as carbon sources, cannot ferment arabinos, is free of gas generation during glucose fermentation and is positive to catalase. The strain is used for production of the 2-keto-D-gluconic acid. Production of the 2-keto-D-gluconic acid by the strain is high in glucose conversion ratio and less in by-products, and the obtained 2-keto-D-gluconic acid is high in purity.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Preparation method of fruit and vegetable fermentation liquid

InactiveCN106261414AFresh fermentationTaste coordinationAcidic food ingredientsFlavorLactic acid bacterium

The invention discloses a preparation method of fruit and vegetable fermentation liquid. The method includes the main steps of taking fresh fruits and vegetables to be peeled and then juiced, conducting filtering to remove solid particles to obtain fruit and vegetable clear juice, adding white granulated sugar so that the content of solids in the juice can reach 10-15%, adding the juice into a fermentation tank to be subjected to pasteurization, inoculating lactic acid bacteria for fermentation at 35-45 DEG C when the temperature is cooled to be 45 DEG C or below, inputting the fermentation liquid into a reaction column through a pump during fermentation, making the fermentation liquid return to the fermentation tank after the liquid passes through the reaction column to form circulation, stopping fermentation when the pH is reduced to 3.3-4.3 through fermentation, discharging fermentation liquid to be filtered to be clear and subjected to pasteurization, and conducting canning to obtain the fruit and vegetable fermentation liquid. The fruit and vegetable fermentation liquid prepared through the method gives people a fresh fermentation feeling, is acidic but free of stale flavor, is coordinative in taste and free of alcohols, and can be directly drunk. The fermentation liquid further contains lots of glucuronic acid, D-gluconic acid-1,4-lactone and other functional components besides epigenetic components produced during metabolism of lactic acid bacteria. The method is simple in preparation process and simple in industrial enlargement.

Owner:陈爱梅

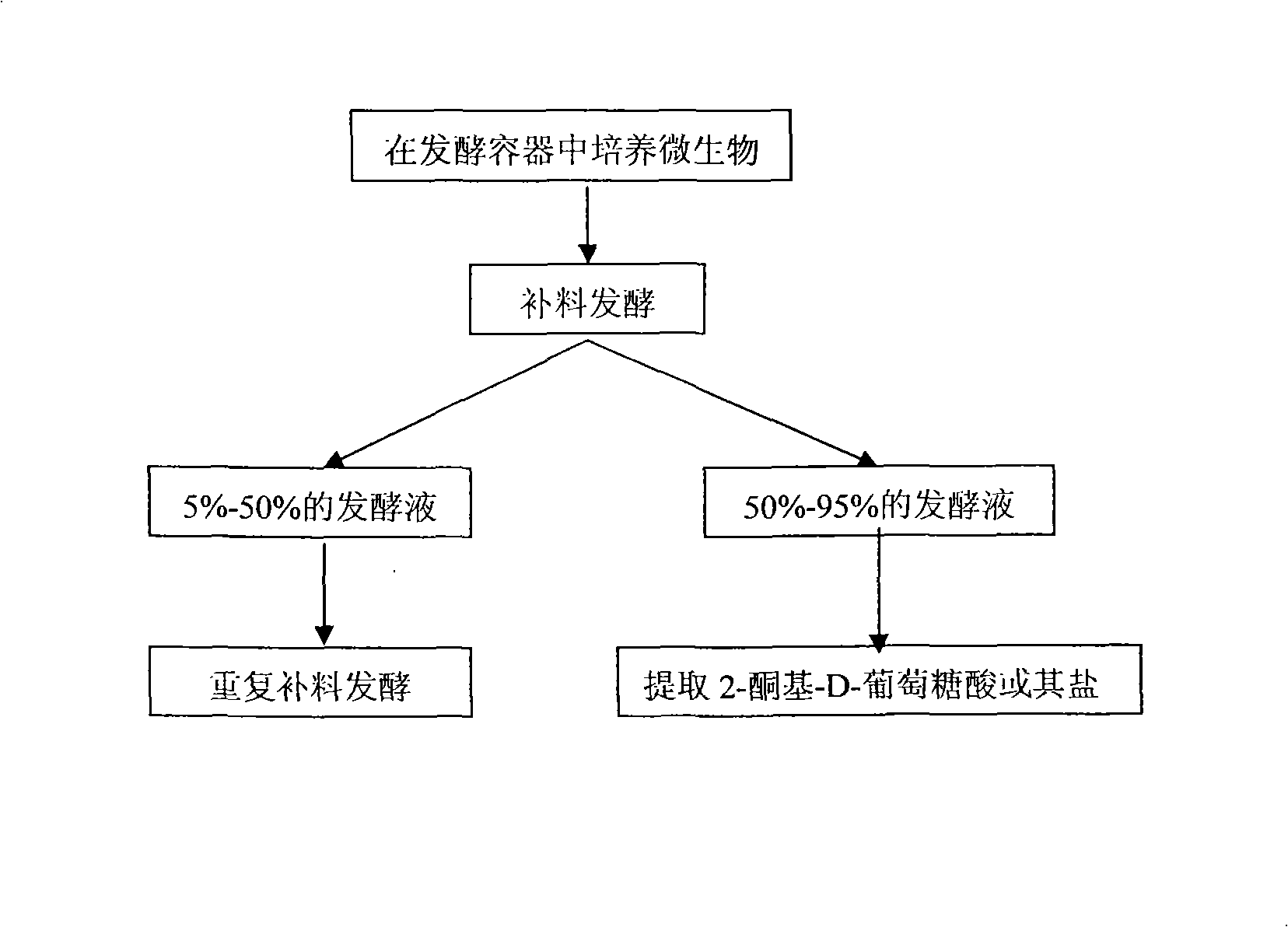

2-keto-d-gluconic acid semicontinuous fermentation process

The invention relates to a method for fermentation production of 2-ketone-D-gluconic acid and salt thereof in high yield from glucose or amylum hydrolysis sugar. The method is realized through semicontinuous fermentation, namely the repeated feeding and batch fermentation technology. The method comprises the following steps: a microorganism with the capacity of converting the glucose into the 2-ketone-D-gluconic acid is cultured in a fermentation vessel; a culture medium containing the glucose is fed into the fermentation vessel until the culture medium is 60 to 85 percent of the volume of the fermentation vessel; after feeding is completed, 50 to 95 percent of fermentation broth is released from the fermentation vessel so as to recover the 2-ketone-D-gluconic acid and the salt thereof (the concentration of the glucose in the fermentation broth is lower than 2 grams per liter at the time); and residual fermentation broth in the fermentation vessel is taken as a seed to perform repeated feeding and batch fermentation.

Owner:江西省德兴市百勤异VC钠有限公司 +2

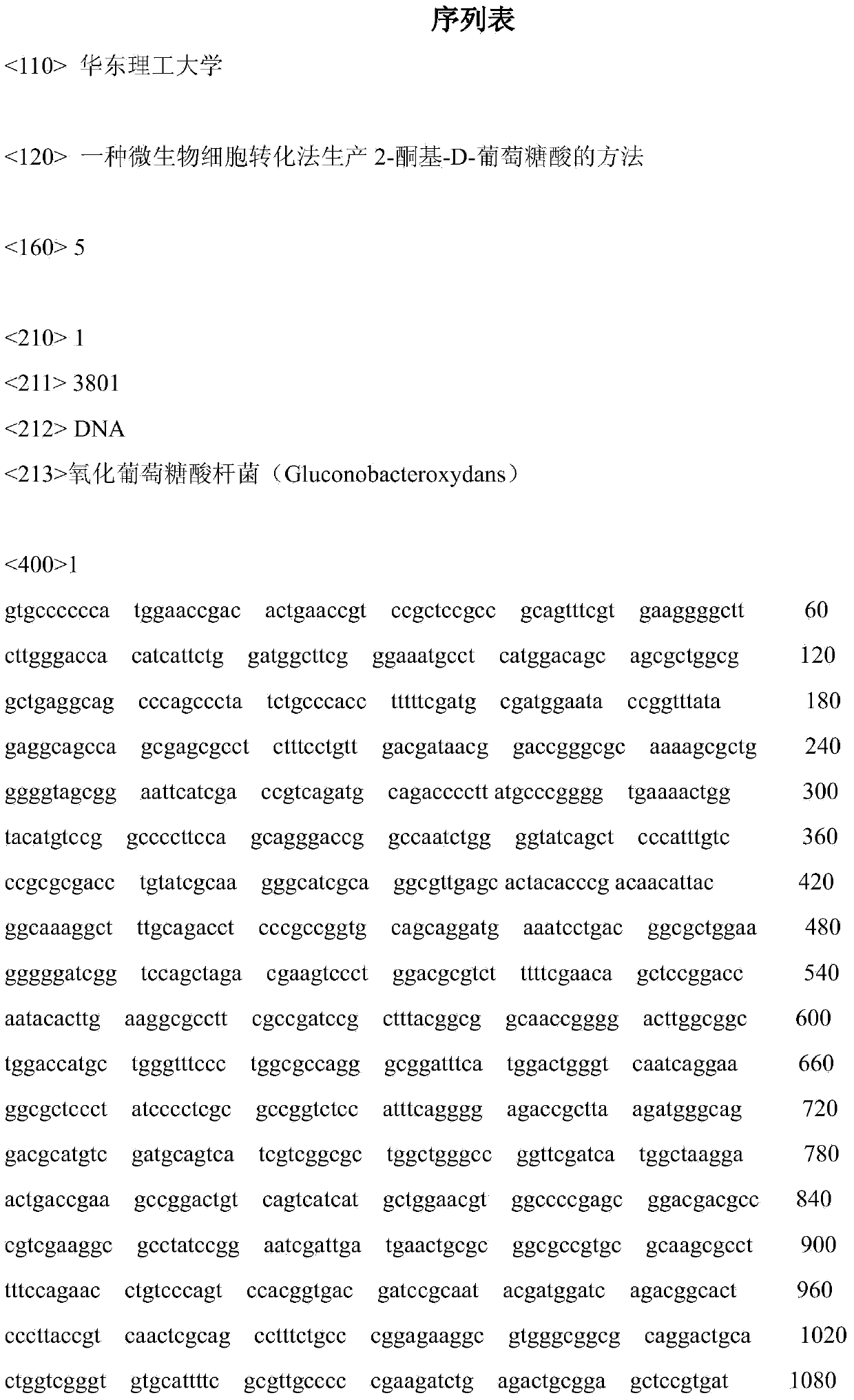

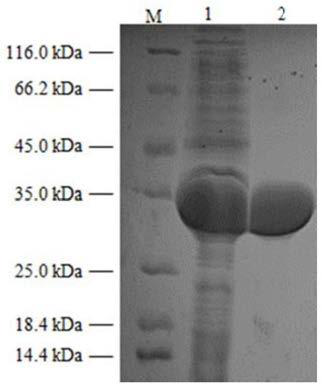

Microbial cell conversion method for producing 2-keto-D-gluconic acid

ActiveCN103627740AEasy to recycleEasy to separate and purifyBacteriaMicroorganism based processesMicroorganismNucleotide

The invention provides a microbial cell conversion method for producing 2-keto-D-gluconic acid. The method comprises the steps of A. preparing resting cells with a genetic engineering strain of gluconobater oxydans DSM2003 as a strain, wherein the genetic engineering strain is gluconobater oxydans of overexpressing gluconic acid dehydrogenase, and the gene of the gluconic acid dehydrogenase comes from the gluconobater oxydans and has a nucleotide sequence as shown by SEQ ID NO:1; B. preparing a conversion liquid containing glucose or gluconic acid, wherein the concentration of the glucose is 200-250g / L, and the concentration of the gluconic acid is 200-300g / L; and C. adding 30-60g / L of resting cells into the conversion liquid for converting so as to obtain the 2-keto-D-gluconic acid. The method has the advantages that the conversion rate is high, the product is single, the separation and purification are simple, the production cost is saved, the cells are easy to recycle and are reusable, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for indirectly preparing D-sodium erythorbate

ActiveCN105603018AIncrease productionImprove conversion rateMicroorganism based processesFermentationGluconic acidSodium erythorbate

The invention discloses a method for indirectly preparing D-sodium erythorbate, belonging to the technical field of biochemical separation synthesis. The method comprises the following steps: by using a Serratia marcescens SDSPY-136 strain fermentation liquid as a raw material, carrying out fermentation liquid pretreatment, methyl 2-keto-D-gluconate reaction and conversion reaction to obtain crude D-sodium erythorbate; and carrying out refinement and purification to obtain the D-sodium erythorbate product. The Serratia marcescens is used as a production strain to obtain the calcium 2-keto-D-gluconate, and multiple impurity removal modes are combined to convert the treatment liquid into the D-sodium erythorbate. The obtained fermentation liquid has the advantages of high 2-keto-D-gluconic acid yield and high conversion rate; the crude D-sodium erythorbate product has high purity and is easy to refine, so the total yield is enhanced; and the method has favorable popularization and application prospects.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Blueberry chew product and preparation method thereof

The invention discloses a blueberry chew and a preparation method thereof. The blueberry chew is prepared from blueberry freeze-dried powder, purple sweet potato powder, xylitol, dextrin, D-gluconic acid delta lactone (calcium carbonate) and magnesium stearate through processing. The preparation method comprises the following steps: performing freeze-drying on blueberries, and crushing into powder with a certain particle size; and adding the purple sweet potato powder, mixing according to a certain ratio, adding auxiliary materials according to the ratio, and performing compression molding to obtain the blueberry chew. Due to adoption of the technical scheme, compared with an existing product, the blueberry chew has the advantages that due to the addition of the purple sweet potato powder, the anthocyanin content is increased; in addition to the original various nutritional ingredients in the blueberries, various nutritional ingredients in the purple sweet potato are increased, so that various health-care effects of the purple sweet potato in the product are increased on the basis of the blueberries on the human nutritional health-care effect; the purple sweet potato powder is matched with the blueberries, stabilization of the anthocyanin in the product is promoted, and nutrition and health care and maintenance of consumers are promoted. The blueberry chew is bright in color.

Owner:大连卓尔高科技有限公司

Method for producing 2-keto-D-gluconic acid by using fermentation method

InactiveCN102925499AImprove conversion rateEasy to controlMicroorganism based processesRecombinant DNA-technology2,3-ButanediolGluconic acid

The invention discloses a method for producing 2-keto-D-gluconic acid by using a fermentation method, which is used for producing the 2-keto-D-gluconic acid by using Lebsiella pneumoniae with a lost 2,3-butanediol synthetic route as a production strain and glucose as the raw material through controlling a fermentation liquor to be acidic under an aerobic fermentation condition. The method has the following characteristics of relatively high transformation rate, easily-controlled fermentation process and relatively low temperature reducing energy consumption in a fermentation process.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

High concentration fermentation process of 2-keto-D-gluconic acid mixed salt

InactiveCN101575621APromote crystallizationQuality improvementMicroorganism based processesFermentationHigh concentrationConcentrations glucose

The invention discloses a high concentration fermentation process of 2-keto-D-gluconic acid mixed salt, comprising the following steps: adding the culture medium which contains glucose, corn steep liquor and light calcium carbonate to a fermentation vessel; introducing the bacteria seeding liquid; adding sodium carbonate solution or sodium hydroxide solution in a fed-batch way when the light calcium carbonate in the fermentation vessel runs out; starting to add the glucose solution with the concentration of 300g / L to 500g / L in batches or in fed-batch way when the concentration of the glucose solution in the fermentation culture medium drops to 20g / L to 100g / L; controlling the gross sugar concentration of the fermentation fluid terminal point to 150g / L to 300g / L until the remaining sugar concentration is below 2g / L and the fermentation finishes. The invention solves the problem that the 2-keto-D-calcium gluconate salt is easy to be crystallized, improves the quality of D-iso ascorbic acid and the salt finished products thereof, and puts the discharge of solid waste calcium sulphate waste residue to an end.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

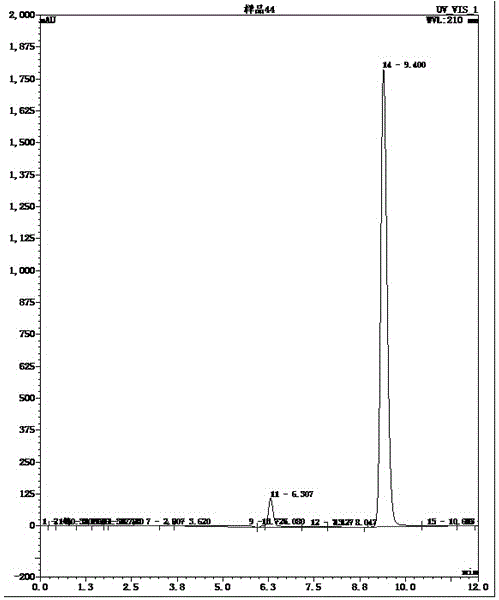

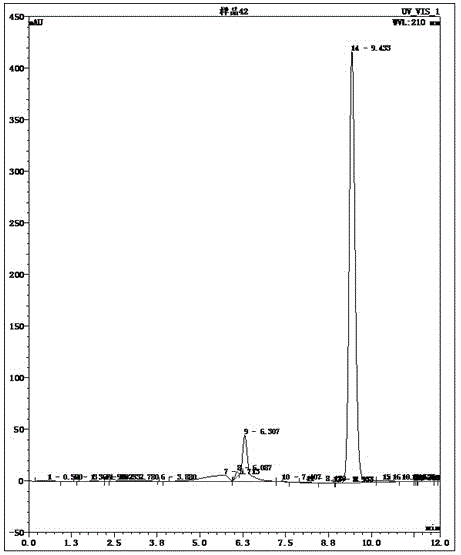

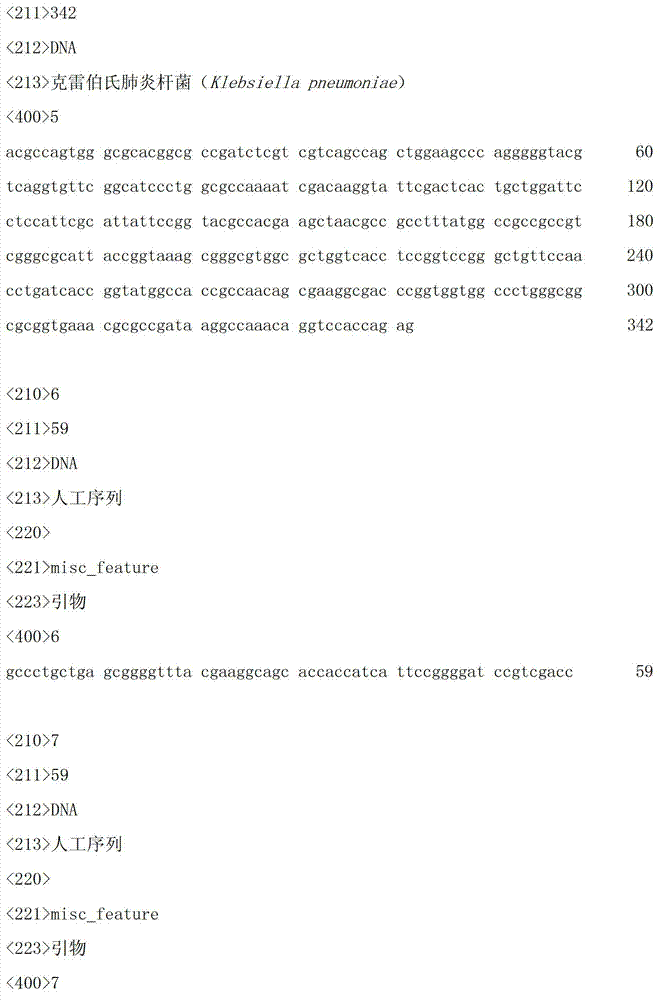

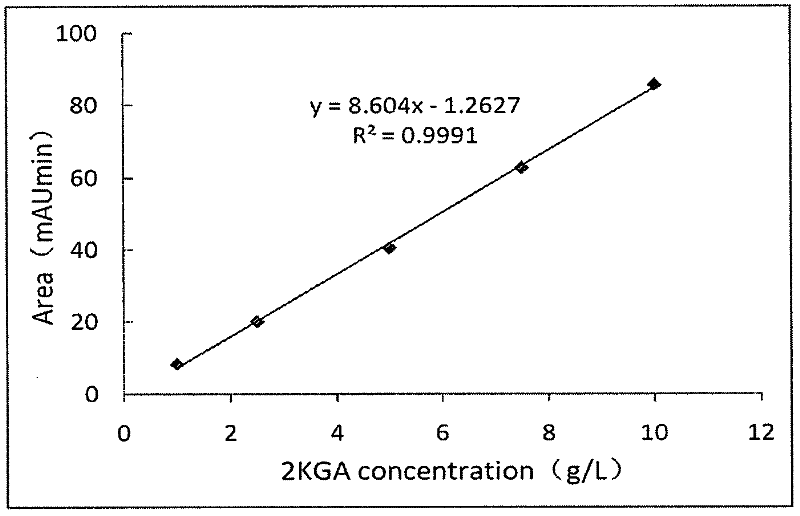

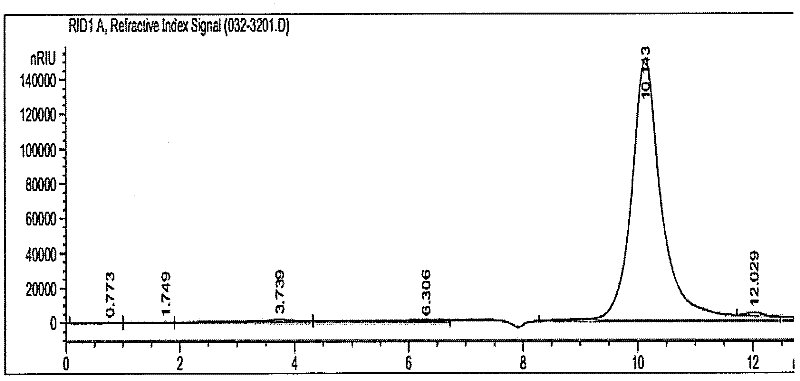

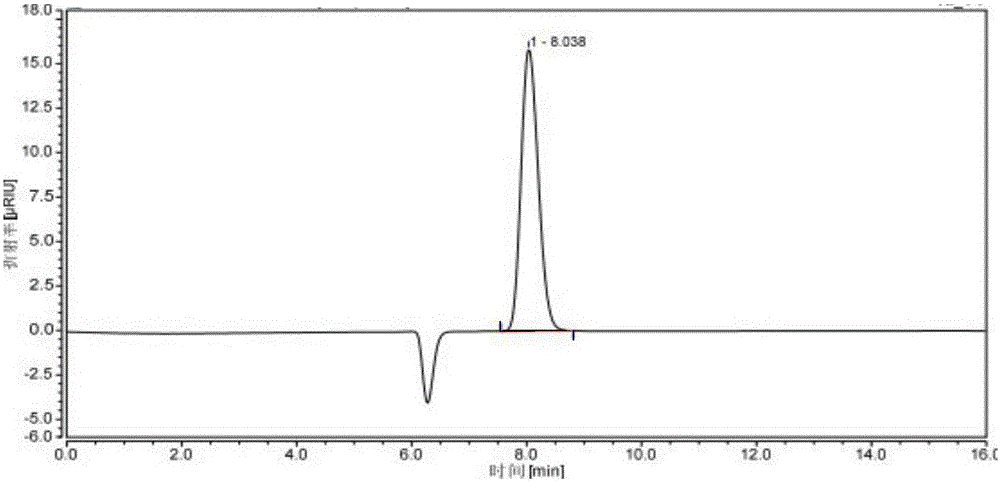

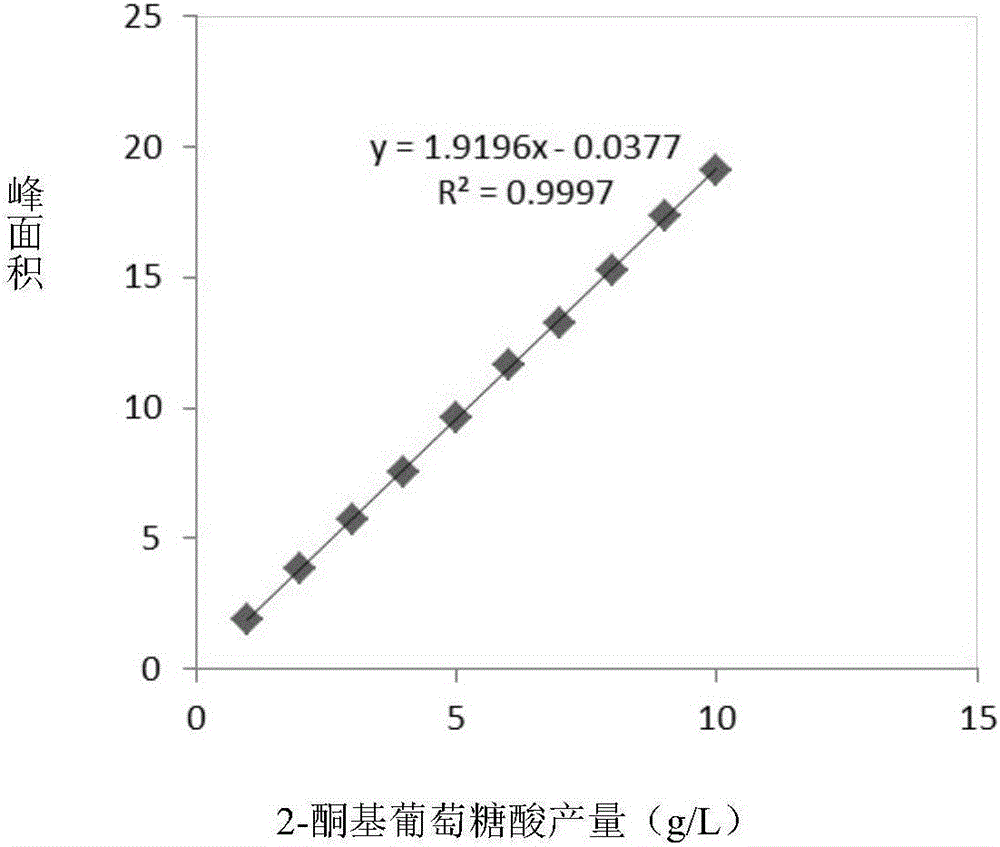

Screening method for 2-keto-D-gluconic acid high-yield bacterial strain, and fermentation method of such bacterial strain

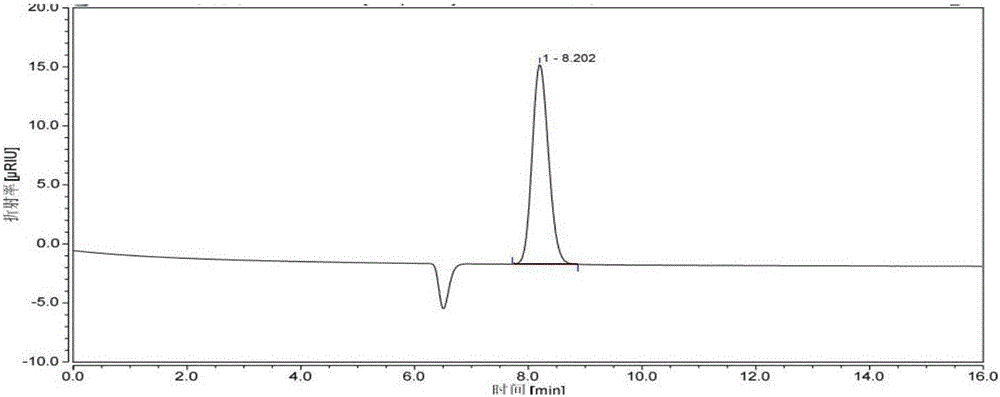

The invention discloses a screening method for a high-yield 2-keto-D-gluconic acid Serratieae bacterial strain, and the application of the bacterial strain for producing 2-keto-D-gluconic acid, belonging to the field of biological engineering. The screening method comprises the following steps of: weighing about 0.2 g of soil, adding the soil in 20 ml 0.85% of sterile normal saline, mixing uniformly via shaking, coating the bacterial suspension on a beef extract peptone culture medium with salt concentration of 5%, culturing for 36 hours at 30 DEG C, culturing the bacterial colony of the purplish red pigment in a fermentation medium, then, executing qualitative analysis via a high performance liquid chromatograph by an internal standard method, and identifying the screened bacterial strain on the aspects of morphology, physiology and biochemistry, and molecular biology, so as to get one high-yield 2-keto-D-gluconic acid Serratieae bacterial strain; the invention also discloses a method for producing the 2-keto-D-gluconic acid by the bacterial strain, and yield of the 2-keto-D-gluconic acid produced by fermentation according to the method is 181.2g / L.

Owner:JIANGNAN UNIV

Technique for producing 2-keto-D-gluconic acid by fermentation of gluconate

ActiveCN101555498ASimple recipeShort fermentation cycleMicroorganism based processesFermentationFood additiveGlucose polymers

The invention pertains to the field of preparing the salt synthetic precursor of a food additive, namely, 2-keto-D-gluconic acid, in particular to a technique for producing the 2-keto-D-gluconic acid by fermentation of gluconate; wherein the gluconate is used as the carbon source in a fermentation medium for fermentation culture. The invention has simple formulation of fermentation medium, short fermentation period, lower cost, no need of adding of buffer, and less impurity, and is convenient for extraction and purification.

Owner:郑州拓洋生物工程有限公司

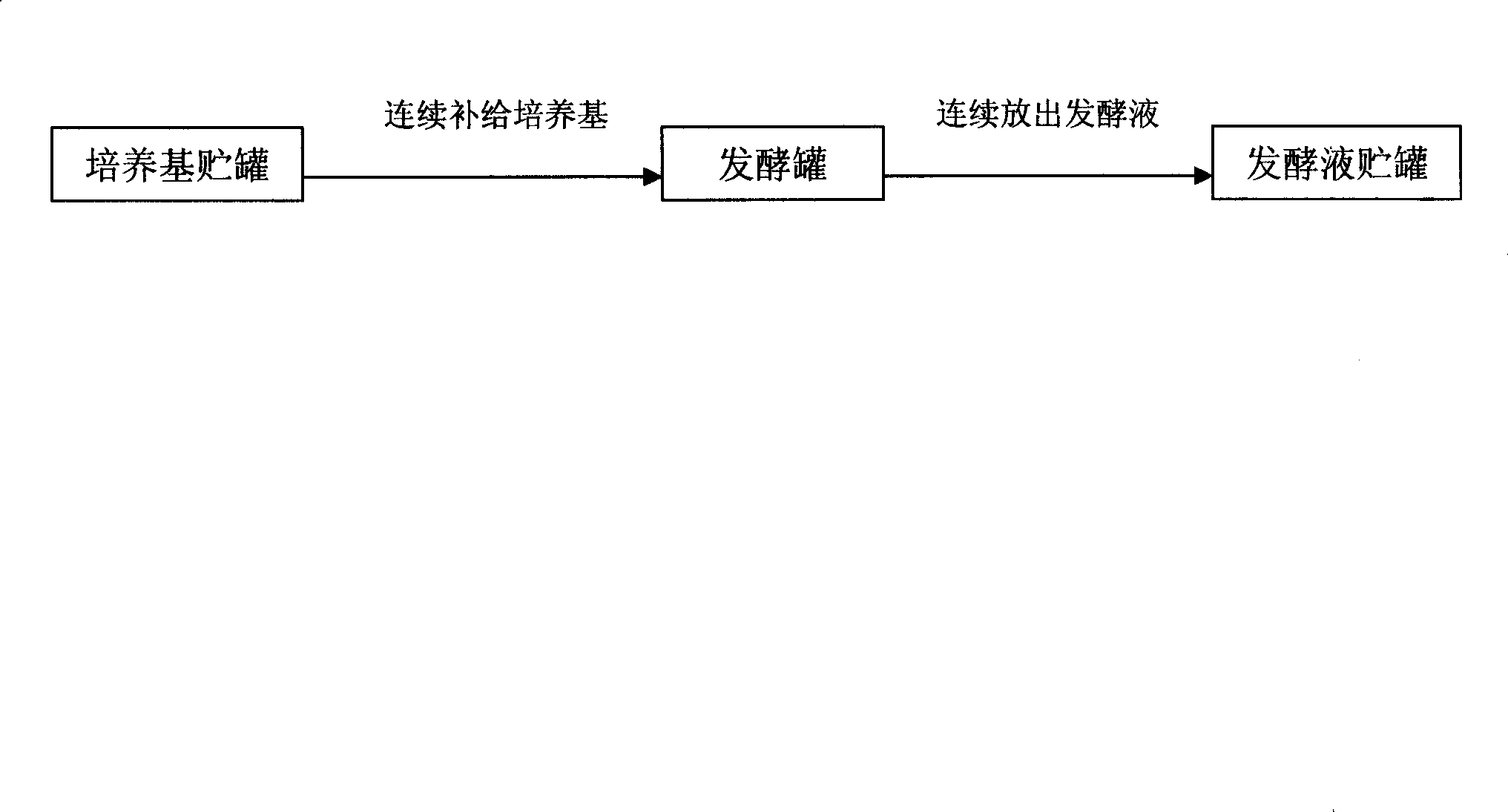

2-keto-d-gluconic acid continuous fermentation process

A method for fermenting and producing 2-ketone group-D-gluconic acid and salts thereof from glucose or starch hydrolysate sugar by continuous fermentation with high yield, comprises the steps that bacterium is transformed into the 2-ketone group-D-gluconic acid by using the glucose or the starch hydrolysate sugar is cultivated in a fermentation vessel; culture medium containing glucose is continuously supplied into the fermentation vessel; by being corresponding to the rate of dilution of zymotic fluid, zymotic fluid is continuously discharged out from the fermentation vessel; the 2-ketone group-D-gluconic acid or the salts thereof is recycled from the zymotic fluid which is continuously discharged out.

Owner:江西省德兴市百勤异VC钠有限公司 +2

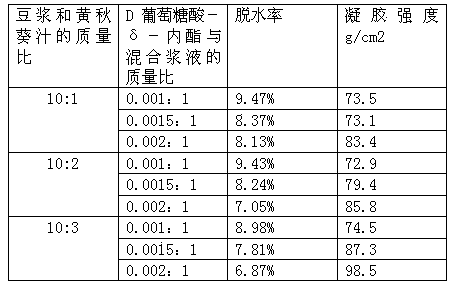

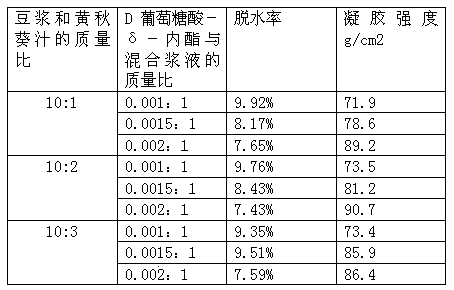

Okra bean curd and preparation method thereof

InactiveCN103621659AImprove nutrition and health valueWith beauty and beautyCheese manufactureFood scienceCholesterolSlurry

The invention discloses an okra bean curd and a preparation method thereof. The okra bean curd is prepared by taking soya-bean milk as a primary material, okra juice as an auxiliary material and D gluconic acid-sigma-lactone as a coagulator, mixing the cooked and filtered soya bean milk with the okra juice and using D gluconic acid-sigma-lactone to coagulate through flower-growing and forming, wherein the mass ratio of dry soybeans to water in the soy bean milk is 1:(5-6), the mass ratio of the soy bean milk to the okra juice is 10:(1-3), and the mass ratio of the D gluconic acid-sigma-lactone to mixed slurry is (0.001-0.002):1. The bean curd prepared by the preparation method disclosed by the invention is not only rich in nutrition, but also has health effects of maintaining beauty and keeping young, protecting gastric mucosa, delaying ageing, lowering cholesterol, improving the immunity, and the like, can be used for reducing the application of a halogen gas blowing agent, further shortening the production time and greatly improving the product gel strength and the dehydration rate, so that the product is smooth, fine and richer in nutrition; moreover, bad mouthfeel of the okra can be overcome, so that the okra bean curd is suitable for industrial production.

Owner:SICHUAN YANGCHUN HORTICULTURAL

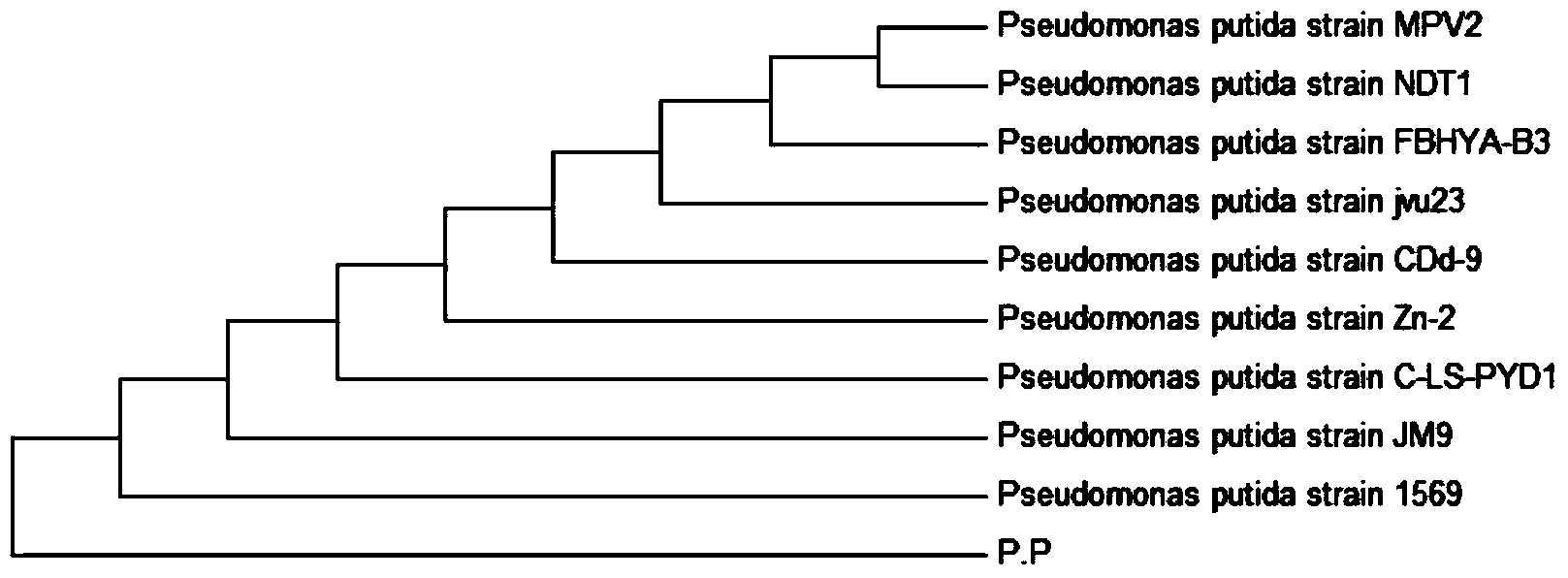

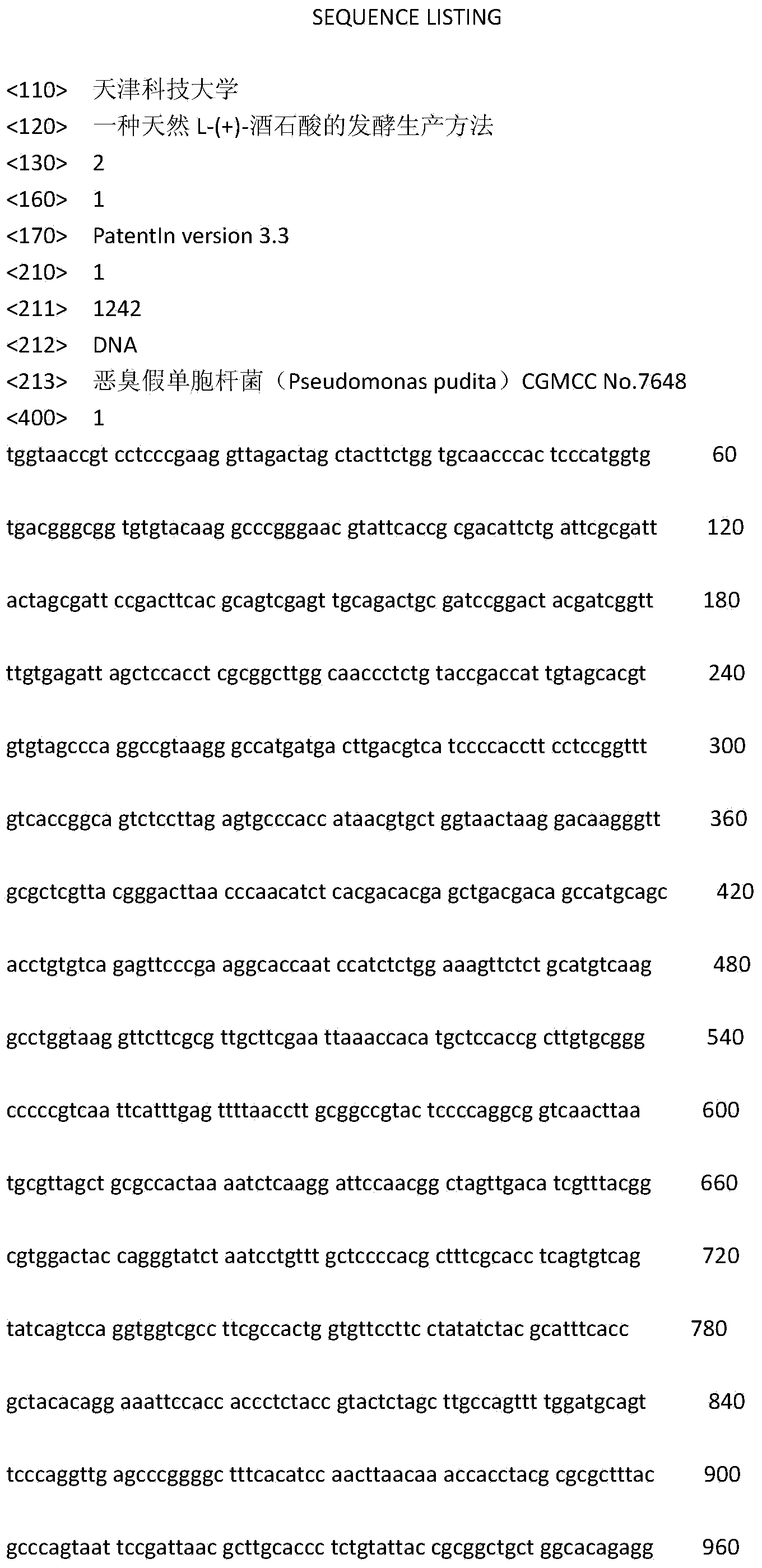

Fermentation production method for natural L-(+)-tartaric acid

InactiveCN103509746AMeet needsSimple processBacteriaMicroorganism based processesMicroorganismPseudomonas putida

The invention discloses pseudomonas putida for producing natural L-(+)-tartaric acid by using 5-keto-D-gluconic acid and salt thereof, and a production method of the pseudomonas putida. The pseudomonas putida mutant strain TUST is preserved in the Common Microorganism Center (CGMCC) of the China Microorganism Culture Preservation and Management Committee on May 28th, 2013, the preservation number is CGMCC No.7648. The natural L-(+)-tartaric acid can be produced from the strain by using 5-keto-D-gluconic acid and salt thereof, the fermentation yield of a shake flask is 1.6g / L, which is 12% of an theoretical value, the fermentation strength is 3% per day, the fermentation yield of a fermentation tank is 7.1g / L, which is 24% of the theoretical value, the fermentation strength is 4% per day, the fermentation product is natural L-(+)-tartaric acid, and moreover the production process is simple and less pollution is caused. Due to adoption of the strain and the production method, a novel process is provided for the production of natural L-(+)-tartaric acid in China, and the economic values of the natural L-(+)-tartaric acid are effectively improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for producing 2-keto-D-gluconic acid by high-concentration fermentation

ActiveCN102747113AImprove qualityLess impuritiesMicroorganism based processesFermentationOptimal growthSolvent

The invention discloses a process for producing 2-keto-D-gluconic acid by high-concentration fermentation. A microorganism for converting glucose into the 2-keto-D-gluconic acid or salt of the 2-keto-D-gluconic acid is cultured in a fermentation container, as a carbon source in a fermentation culture medium, the glucose is subjected to fermentation culture, and the pH (Potential Of Hydrogen) value before sterilization is 5.5-7.0; and the fermentation culture medium consists of the following substances by massvolume: 10-32% of glucose, 0.1-1% of maize pulp, 1-5% of calcium hydroxide, 0.02-0.08% of de-foaming agent and a solvent as water. The pH value is adjusted by calcium hydroxide in the beginning of fermentation so that the cost is lower, the pH value of a fermentation solution is more accurately adjusted and controlled by liquid ammonia or ammonia water in the mid- to late-period of fermentation so that the fermentation solution is kept in the environment for optimal growth and acid production of the microorganism, and a nitrogen source is supplied at the same time, so that the acid production rate and the acid production concentration of bacteria are increased, the fermentation conversion rate and the yield are increased, the fermentation cycle is shortened, the quality of the fermentation liquid is high, the amount of the impurity is small, the extracting and purifying processes are convenient, and the emission of calcium sulfate waste residues is reduced at the same time; and the formed byproduct is ammonium sulfate which can be used as a fertilizer.

Owner:郑州拓洋生物工程有限公司

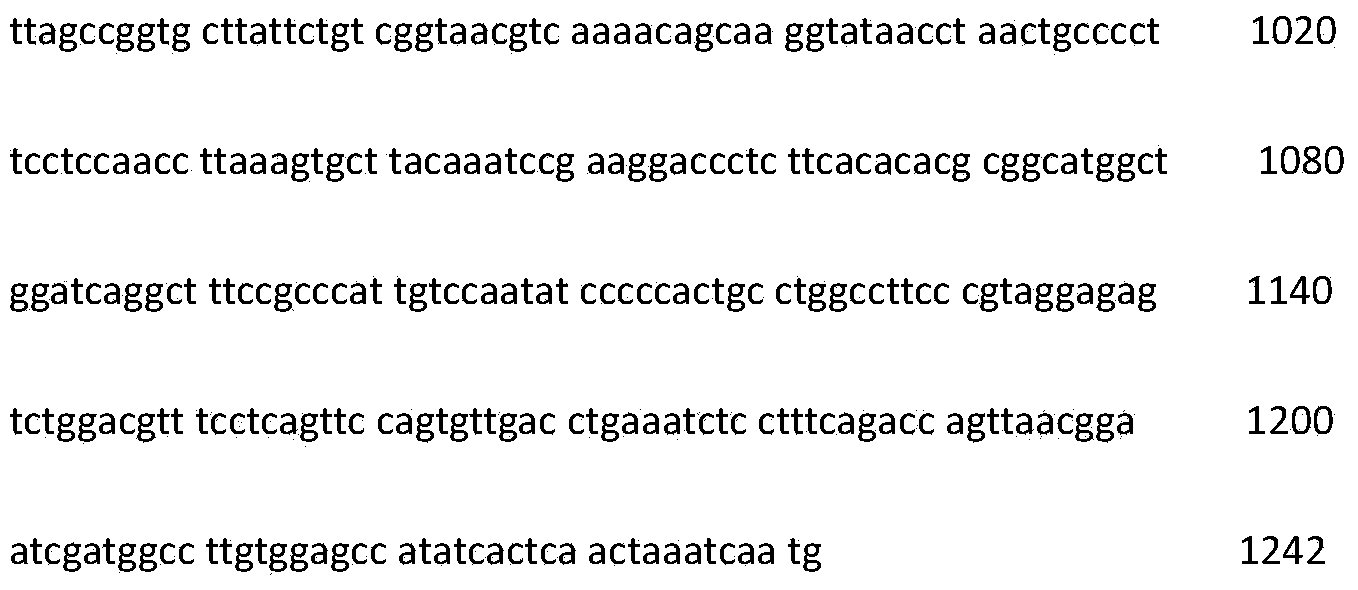

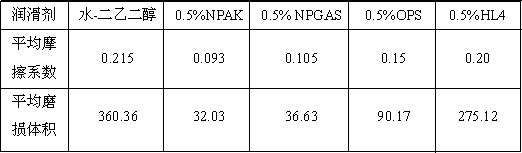

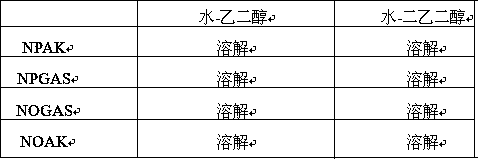

Small-molecule functionalized surfactant and preparation method and application thereof

ActiveCN107827926AReduce corrosionImprove the lubrication effectOrganic compound preparationGroup 5/15 element organic compoundsQuaternary ammonium cationSalicylic acid

The invention discloses a small-molecule functionalized surfactant. The surfactant is water-soluble functionalized quaternary ammonium ionic liquid, the cations of which are quaternary ammonium cations with different alkyl chain lengths and the anions of which are acetylsulfoacid radical, saccharinic acid radical, salicylic acid radical, glycine radical, D-gluconic acid radical, citric acid radical and dihydrobutanedioic acid radical. The invention further discloses a preparation method of the surfactant and application of the surfactant as a water-soluble lubricating additive.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

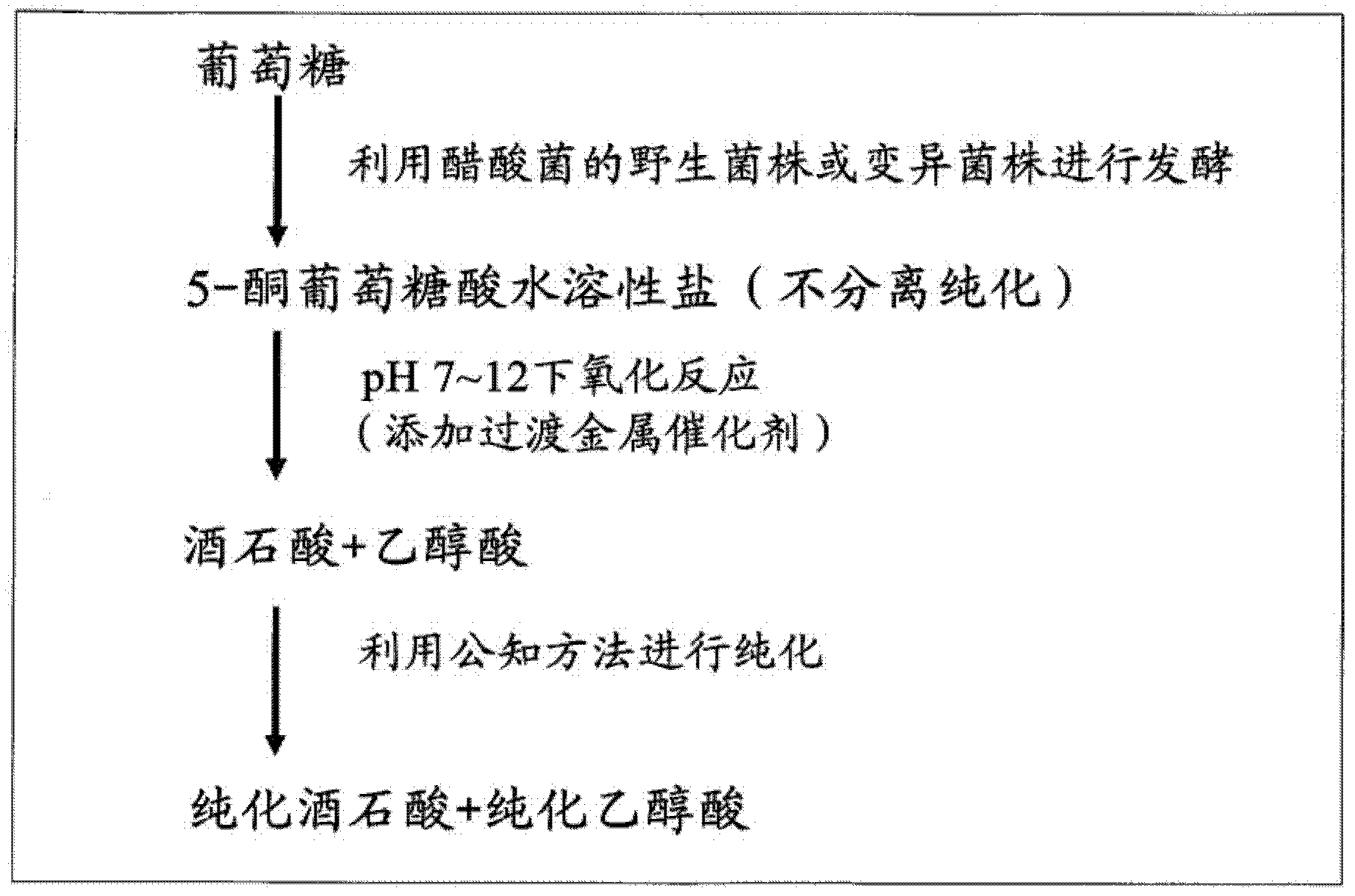

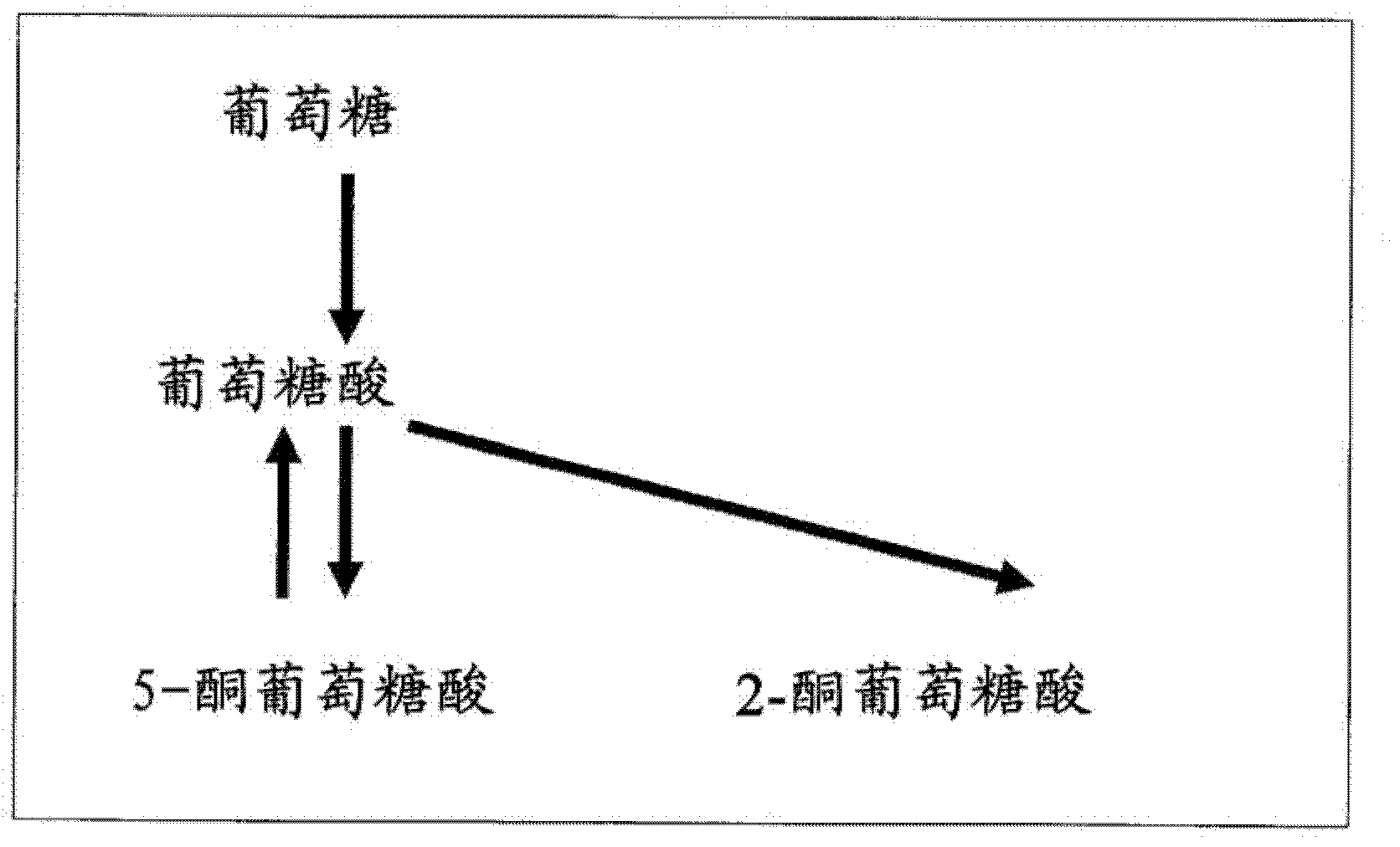

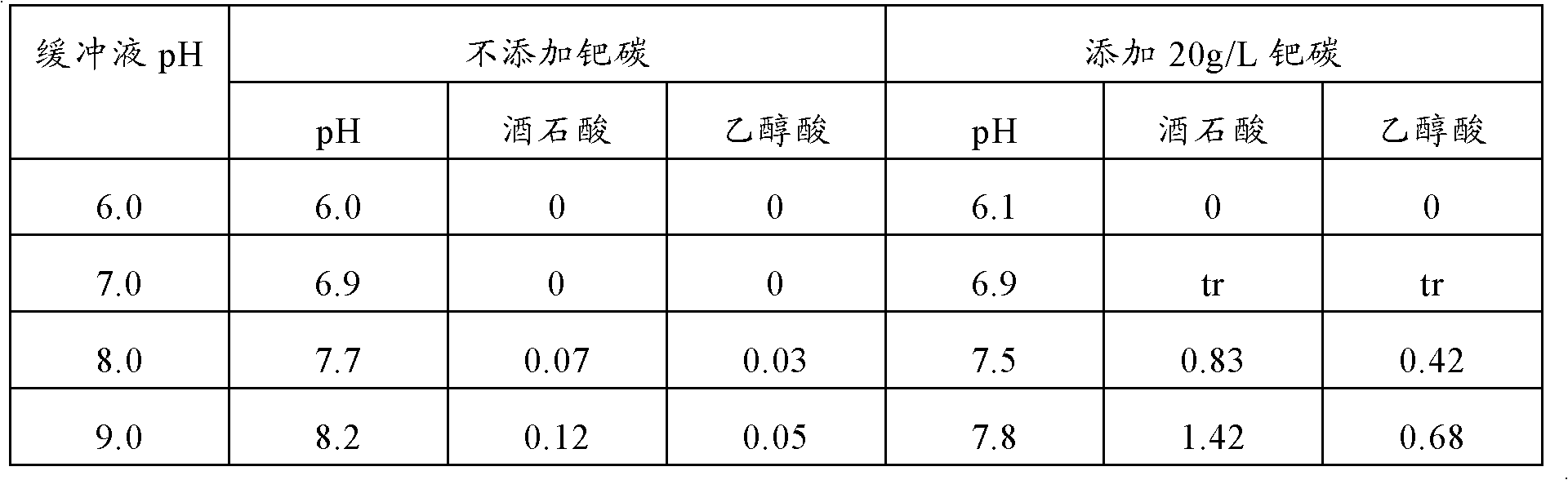

Process for production of organic acids

InactiveCN102471786AImprove practicalityOrganic-compounds/hydrides/coordination-complexes catalystsFermentationGluconic acidKetone

Disclosed is a process for producing L-tartaric acid or a salt thereof and / or glycolic acid or a salt thereof from glucose, which comprises the following steps (A) to (C): (A) culturing a microorganism capable of producing 5-keto-D-gluconic acid from glucose in a glucose-containing culture medium in the presence of an alkali capable of producing a water-soluble salt of 5-keto-D-gluconic acid, thereby producing a culture containing a water-soluble salt of 5-keto-D-gluconic acid; (B) adjusting the pH value of the culture containing the water-soluble salt of 5-keto-D-gluconic acid, which has been produced in step (A), to 7 to 12 and retaining the culture at that pH value, thereby producing a reaction solution in which the water-soluble salt of 5-keto-D-gluconic acid is converted into L-tartaric acid or a salt thereof and / or glycolic acid or a salt thereof; and (C) collecting L-tartaric acid or the salt thereof and / or glycolic acid or the salt thereof from the reaction solution which has been produced in step (B).

Owner:HYPHAGENESIS

Method of extracting tartaric acid by fermenting grape pips

InactiveCN103602709ASimple methodEasy to operateMicroorganism based processesFermentationAcetic acidGluconic acid

The invention discloses a method of extracting tartaric acid by fermenting grape pips, and relates to the technical field of extraction methods. The method comprises the following steps: adding residual grape pips after juicing into tartaric acid fermentation bacteria (dissociants of Gluconoba-cter suboxydans); fermenting for 5-6 days at 30 DEG C; forming tartaric acid by oxygenolysis of glucose by way of 2,5-diketo-D-gluconic acid while forming hydroxyacetic acid, wherein the melting point of tartaric acid is 171-174 DEG C, and the melting point of hydroxyacetic acid is 78-79 DEG C. The tartaric acid is separated and purified according to great disparity of the melting points of tartaric acid and hydroxyacetic acid. The method disclosed by the invention is simple, convenient for actual operation, high in extraction rate and good in product purity, and has good economical benefit.

Owner:界首市鸿丰生物助剂加工厂

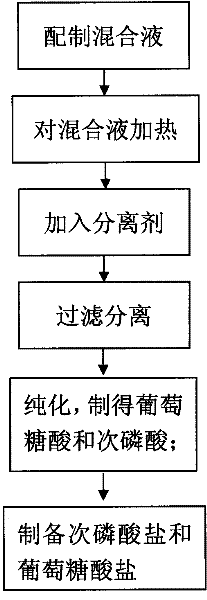

Method for preparing hypophosphorous acid (salt) and gluconic acid (salt) from glucose phosphate serving as raw material

InactiveCN102190578AEasy to getLow costCarboxylic acid salt preparationHypophosphorous acidPhosphateGluconic acid

The invention discloses a method for preparing hypophosphorous acid (salt) and gluconic acid (salt) from glucose phosphate serving as a raw material, which comprises the following steps of: (1) preparing raw materials: preparing subphosphate or acid phosphate and glucose, and taking water as a solvent; (2) heating: continuously heating mixed solution at the temperature of more than or equal to 100DEG C under the air pressure of more than or equal to 0.01MPa for more than 10 minutes; (3) separating: adding a separating agent, concentrating, and separating to obtain crude products of gluconic acid salt and hypophosphorous acid salt; (4) purifying: filtering to remove precipitates to obtain gluconic acid, adding a gas or a solvent capable of reacting with the hypophosphorous acid salt into aqueous solution of the separated hypophosphorous acid salt, and filtering to remove precipitates to obtain hypophosphorous acid; (5) preparing the hypophosphorous acid salt: reacting the hypophosphorous acid with basic oxide or hydroxide to obtain the hypophosphorous acid salt; and (6) preparing the gluconic acid salt: reacting the gluconic acid with basic oxide or hydroxide to obtain the gluconicacid salt. The production process is environment-friendly and harmless, raw materials are readily available, the cost is low, the yield is high, the period is short and the safety is achieved.

Owner:石允生

Method for preparing fructan and gluconic acid by using inulin

The invention discloses a method for preparing fructan and gluconic acid by using inulin and belongs to the technical field of separation and purification. The method comprises the following steps: by taking commercially available inulin as a raw material, preparing a sucrase hydrating solution; preparing glucose oxidase treating fluid; preparing an ultrafiltration separating solution; preparing a gluconic acid separating solution; preparing a gluconic acid concentrated solution; preparing a fructan separating solution; preparing fructo-oligosaccharide powder and polyfructose powder, thus obtaining two fructan powder and gluconic acid solution with the mass percent concentration of 10 to 15 percent. According to the technical scheme provided by the invention, a product with high added value is produced by the operations of enzymatic hydrolysis, separation and concentration; the product is high in purity and definite in application; the quality of the product meets the requirement of market; used production equipment is industrial equipment, namely separating devices such as a nanofiltration device, an ultrafiltration device, a reverse osmosis device and an electrodialysis device; the production equipment is mild in separation condition and high in separation efficiency; the adopted raw materials and solvent can be completely utilized, and no three wastes are discharged; the method is a classical green technology and facilitates popularization and application.

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

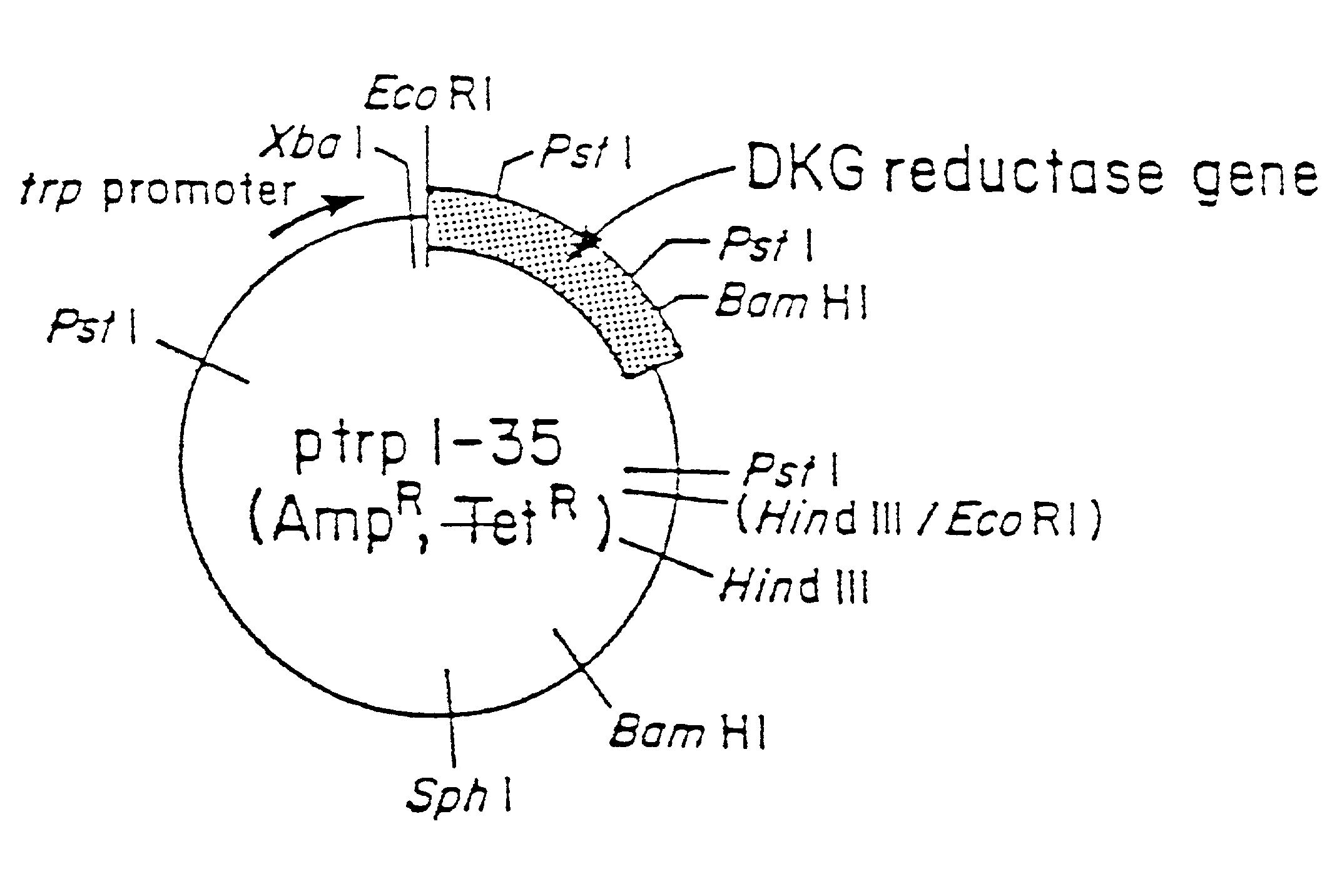

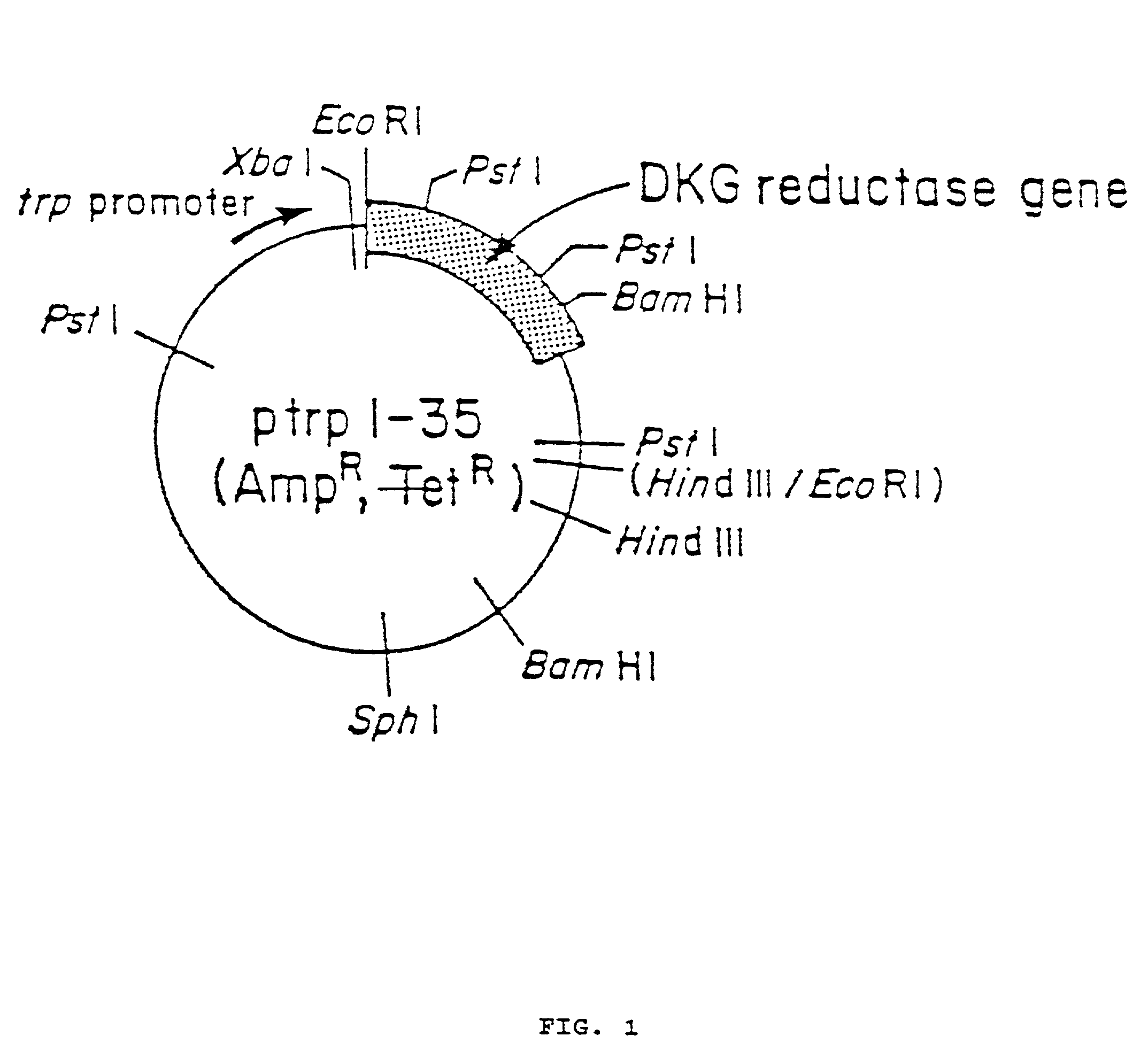

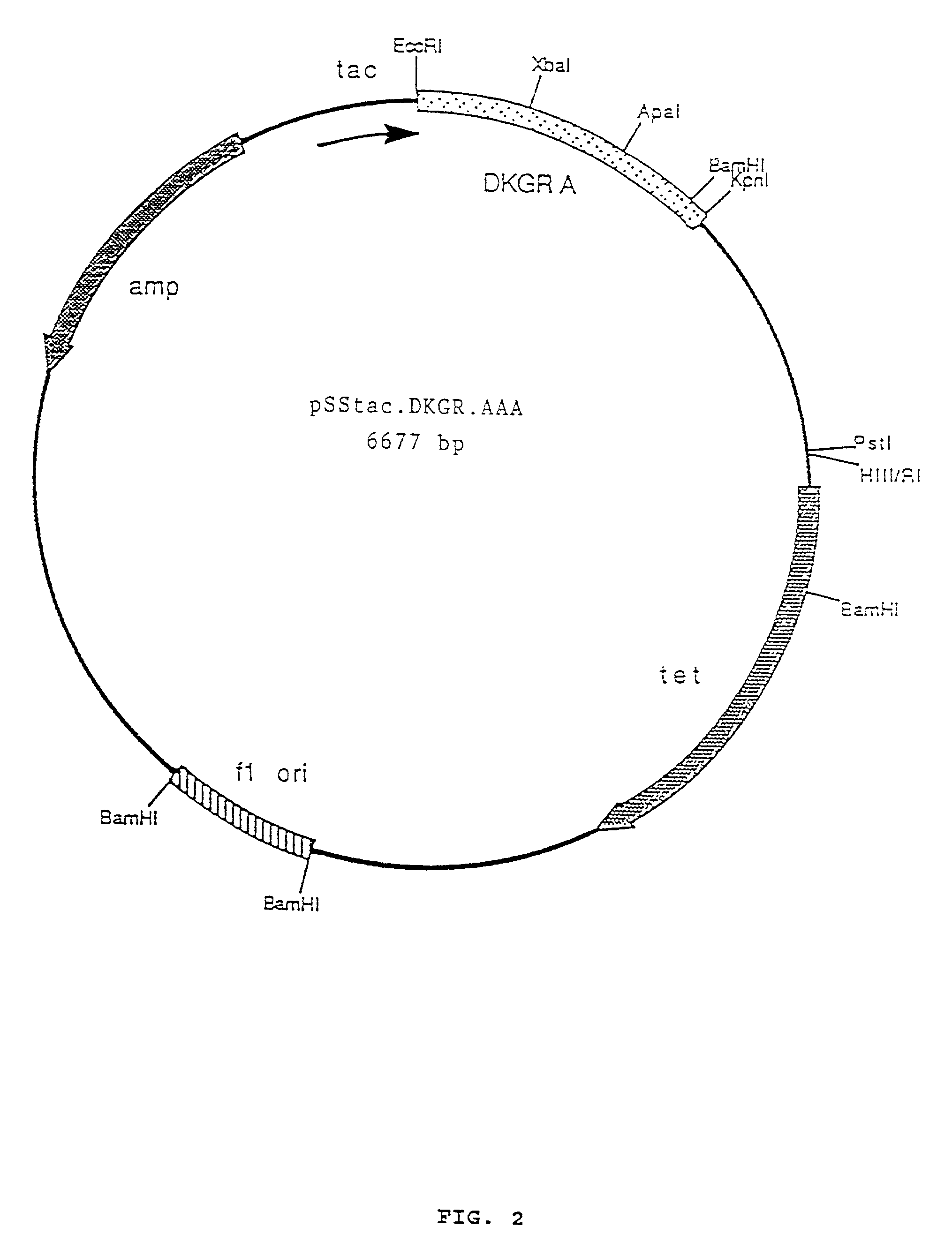

Enzymes for the production of 2-keto-L-gulonic acid

InactiveUS7256027B1High expressionImprove stabilitySugar derivativesBacteriaGluconic acidSite-directed mutagenesis

Mutants of 2,5-diketo-D-gluconic acid reductase A, an enzyme used to produce 2-keto-L-gulonic acid, a precursor of ascorbic acid (vitamin C) are prepared by site-directed mutagenesis. These mutants have increased catalytic activity, increased expression levels, and / or enhanced temperature stability.

Owner:RUTGERS THE STATE UNIV

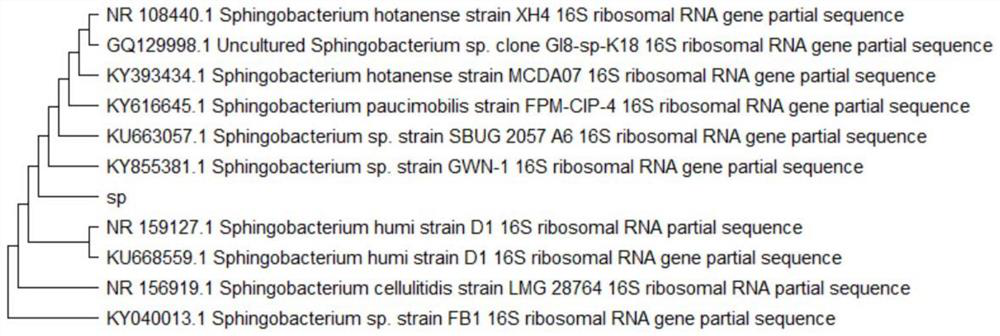

A kind of sphingobacterium and its application and method in catalytic synthesis of l(+)-tartaric acid or its salt

ActiveCN110591954BReduce usageBacteriaMicroorganism based processesMicroorganismSphingobacterium sp.

The invention discloses a sphingobacterium and its application and method in catalyzing the synthesis of L(+)-tartaric acid or its salt. The Sphingobacterium is preserved in the General Microorganism Center of China Microbiological Culture Collection Management Committee, the preservation number is CGMCC No. 18074, and it is named: Sphingobacterium BK99. Sphingobacterium sp. BK99 of the present invention can biosynthesize 5-keto-D-gluconic acid or its salt into L(+)-tartaric acid or its salt, avoiding the use of non-renewable fossil raw materials in the current process; On the other hand, the Sphingobacterium of the present invention replaces the reported method of using rare metals to catalyze 5-keto-D-gluconic acid to synthesize L(+)-tartaric acid, avoiding the use of rare metals.

Owner:HANGZHOU BIOKING BIOCHEM ENG

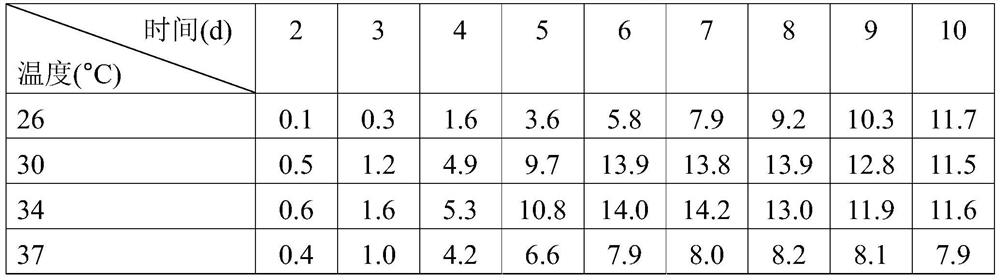

Fermentation process for increasing 2-keto-D-gluconic acid generation velocity of strain

ActiveCN109593796AIncrease productivityImprove conversion rateMicroorganism based processesFermentationGluconic acidMonopotassium phosphate

The invention discloses a fermentation process for increasing the 2-keto-D-gluconic acid generation velocity of a strain and belongs to the field of fermentation process. According to the fermentationprocess, a serratia marcescens SDSPY-623 strain is subjected to strain inclined surface activation, seed culture and fermentation culture in sequence to obtain a 2-KGA containing fermentation liquid,and a fermentation culture medium is prepared from glucose, corn steep liquor, monopotassium phosphate, anhydrous magnesium sulfate, ferrous sulfate, cobalt chloride, ammonium molybdate, boric acid,zinc sulfate, nicotinic acid, calcium carbonate and tap water of which the pH value is 6.5-7.2. By adjusting fermentation culture mediums, fermentation temperatures and pH values and setting sectionalfermentation modes in fermentation culture steps, the conversion rate can be increased, meanwhile, the fermentation cycle is remarkably shortened, the production cost can be reduced, the production efficiency of 2-KGA is improved by 32% or greater when being compared with that of a conventional fermentation process, and the fermentation process has great industrial production significances for abiological fermentation method of 2-KGA.

Owner:QILU UNIV OF TECH +1

Organic acid preparation method

InactiveCN106480113ALow costImprove practicalityOrganic compound preparationOrganic chemistry methodsOrganic acidGlycolic acid

The present invention relates to an organic acid preparation method, which comprises steps A-C, wherein L-tartaric acid or a salt thereof, and / or glycolic acid or a salt thereof is prepared from glucose. The method specifically comprises: (A) culturing microorganisms capable of producing 5-keto-D-gluconic acid through glucose by using a glucose-containing culture liquid in the presence of an alkali capable of making the 5-keto-D-gluconic acid form a water-soluble salt to obtain a culture liquid containing the 5-keto-D-gluconic acid water-soluble salt; (B) adjusting and maintaining the pH value of the culture liquid containing the 5-keto-D-gluconic acid water-soluble salt at 7-12 to obtain a reaction liquid capable of converting the 5-keto-D-gluconic acid water-soluble salt into L-tartaric acid or a salt thereof, and / or glycolic acid or a salt thereof; and (C) extracting the L-tartaric acid or the salt thereof, and / or the glycolic acid or the salt thereof through the reaction liquid obtained in the step (B). According to the present invention, the method is effect, has the low cost, can be used in the industrial preparation, and has the extremely high practicability.

Owner:HENGYANG YISHUN CHEM CO LTD

Biological preservative for preserving shrimps and application thereof

InactiveCN106665798AAntioxidantPrevent oxidative rancidityMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsLoss rateVitamin C

The invention provides a biological preservative for preserving shrimps. The biological preservative is prepared from the following components in parts by weight: 0.02 to 0.6 part of phytic acid, 0.1 to 0.2 part of glucose oxidase, 0.01 to 0.03 part of lysozyme, 0.15 to 0.55 part of succinic acid, 0.5 to 0.9 part of fructus mume powder, 0.3 to 0.8 part of ground cloves powder, 15 to 25 parts of water, 0.0001 to 0.0003 part of nanometer ferric oxide, 0.2 to 0.3 part of antioxidant, and 0.02 to 0.05 part of water retaining agent, wherein the antioxidant contains 0.12 to 0.18 part of vitamin C, 0.05 to 0.07 part of propylgallate and 0.03 to 0.05 part of ethyl acetoacetate; the water retaining agent contains 0.008 to 0.018 part of sorbitol, 0.009 to 0.022 part of glycerin, and 0.003 to 0.01 part of D-gluconic acid. The biological preservative has the beneficial effects that the anti-oxidizing function is realized, the oxidative rancidity of fat and self-degrading function of protein are inhibited, and the loss rate of shrimp nutrition is decreased; the bacteria-inhibiting function is realized, and the increase of total number of bacteria and volatile basic nitrogen is effectively relieved; the water retaining function is good, the water loss rate of the shrimps in the transportation or preservation process is decreased, and the fresh-keeping time of the shrimps is greatly prolonged at the premises of ensuring the flavor and mouth feel of the shrimps.

Owner:ZHEJIANG OCEAN UNIV

Uses of 2,5-dewatering-D-glucitol and the like in preparing cancer treatment medicament

The invention discloses novel application of 2, 5-dehydrated-D-glucitol and an analogue thereof in the preparation of medicaments for treating cancer. The 2, 5-dehydrated-D-glucitol, 2, 5-dehydrated-1-deoxy-D-glucitol and 2, 5-dehydrated-D-gluconic acid can significantly inhibit and kill tumor cells.

Owner:CHINA PHARM UNIV

Method for increasing yield of 2-keto-D-gluconic acid produced by fermentation process

ActiveCN105695520AIncrease productionGood effectMicroorganism based processesFermentationGluconic acidSugar

The invention discloses a method for increasing yield of 2-keto-D-gluconic acid produced by a fermentation process and belongs to the field of fermentation engineering. Serratia sp. ATCC 39006 producing 2-keto-D-gluconic acid is used as a producing strain, dissolved oxygen is controlled to 40%, 64 g, 80 g and 96 g of ammonium sulfate are added respectively at moments of 16 h, 22 h and 28 h of fermentation, 890 g of glucose is added totally five times when residual sugar concentration drops to 15-25 g / L, and optimal fermentation is provided. Upon 44 h of fermentation, the yield of 2-KGA reaches to 265.8 g / L, and the yield is up to 1.03 g / g. The yield of 2-keto-D-gluconic acid is increased from 180.1 g / L to 265.8 g / L by 47.6%, and the effect is significant.

Owner:JIANGNAN UNIV

Gluconic acid montmorillonitenanoribbon and preparation method thereof

The invention relates to a gluconic acid montmorillonitenanoribbon and a preparation method thereof. The gluconic acid montmorillonitenanoribbon is characterized in that bentonite, calcium hydroxide or calcium oxide and gluconic acid are taken as raw materials, sulfuric acid or hydrochloric acid and glycerin are taken as auxiliaries, and the bentonite is subjected to acid activation, base support and gluconic acid modification. The specific technology comprises steps as follows: the bentonite is dispersed in water and is purified through sedimentation, purified montmorillonite is subjected to mineral acid activation and calcium hydroxide support, then a gluconic acid aqueous solution is added and stirred for reaction; and a filter cake is obtained through filtering after the reaction and is washed by an aqueous ethyl alcohol solution and an absolute ethyl alcohol respectively, and room-temperature vacuum drying is performed to obtain the gluconic acid montmorillonitenanoribbon. According to the prepared gluconic acid montmorillonitenanoribbon, the thickness is smaller than 100 nm, the width ranges from 600 nm to2,000 nm, the length ranges from 30 mu m to70 mu m, and the organic ignition loss is 30%-40%.

Owner:GUANGXI UNIV

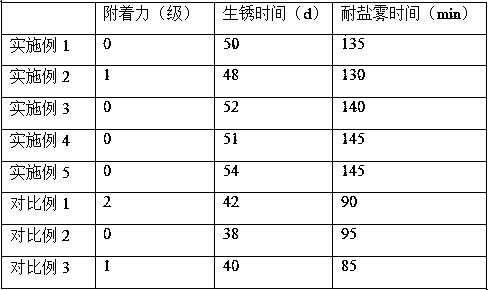

Preparation method of green high-adhesion waterborne anti-rust agent

InactiveCN108505029AGood corrosion inhibition effectReduce corrosionMetallic material coating processesEpoxyGluconic acid

The invention provides a preparation method of a green high-adhesion waterborne anti-rust agent. The preparation method comprises the following steps: S1, preparing modified waterborne epoxy resin; S2, preparing a folium eucalypti extract; S3, weighing components in parts by weight; S4, dissolving inositol hexaphosphate into ethanediol, thus obtaining a mixed solution; then continuously adding deionized water, the modified waterborne epoxy resin, sodium carboxymethyl cellulose, polyaspartic acid, a-D-gluconic acid, lauryl sodium sulfate, dimetyl-(4-(7-acetoxyl-coumarin))-methyl-(2-acryloyloxy)-ethyl-ammonium bromide, the folium eucalypti extract and octyl phenol polyoxyethylene ether, carrying out ultrasonic oscillation, and then regulating pH (Potential of Hydrogen). The green high-adhesion waterborne anti-rust agent prepared by the invention is economic and environment-friendly, is low in cost and safe and harmless in use and has a better anti-corrosion effect, the green high-adhesion waterborne anti-rust agent not only can be used for preventing rusting during manufacturing, but also can be used for preventing rusting during sealing storage, and a very good application prospectis obtained.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Method for co-production of 5-keto-D-gluconic acid and ethyl (S)-4-chloro-3-hydroxybutyrate

The invention discloses a method for co-production of 5-keto-D-gluconic acid and ethyl (S)-4-chloro-3-hydroxybutyrate. Gluconic acid and 4-chloro-3-ethyl acetoacetate are adopted as raw materials, through a double-enzyme coupling system composed of gluconic acid dehydrogenases and carbonyl reductases, the gluconic acid is oxidized to generate the 5-keto-D-gluconic acid, and at the moment, 4-chloro-3-ethyl acetoacetate is reduced to generate the ethyl (S)-4-chloro-3-hydroxybutyrate. By establishing the double-enzyme coupling system, high-yield, low-cost and fast co-production of the 5-keto-D-gluconic acid and the ethyl (S)-4-chloro-3-hydroxybutyrate is achieved; and the system is further suitable for other alcohol dehydrogenase and the carbonyl reductases and is an economical, convenient and effective biocatalysis system with wide applicability.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com