Preparation method of green high-adhesion waterborne anti-rust agent

A water-based anti-rust agent, green technology, applied in the coating process of metal materials, etc., can solve problems such as large environmental pollution, achieve the effects of enhancing adhesion, slowing down corrosion, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

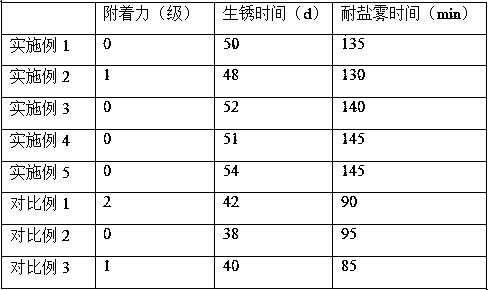

Examples

Embodiment 1

[0014] A preparation method of a green high-adherence water-based antirust agent is characterized in that it comprises the following steps:

[0015] S1. Add ethylene glycol monobutyl ether and absolute ethanol to bisphenol A epoxy resin E-51, heat up to 80°C, stir to disperse the epoxy resin evenly, and then add alanine and phenylalanine Sodium hydroxide aqueous solution of acid composite modifier, control the reaction temperature to 90°C, and the reaction time to 60min to obtain a modified water-based epoxy resin, wherein the molar ratio of alanine:phenylalanine:epoxy resin is 1: 1.5:2;

[0016] S2. Take eucalyptus leaves and add them to 90wt% ethanol to dissolve them, soak them at room temperature for 2 hours, then bathe them in a constant temperature water bath at 75°C for 2 hours, use 90wt% ethanol solution to ultrasonically filter the residue for 0.5 hours, combine the two filtrates, rotary evaporate, add petroleum ether to degrease and decolorize, and concentrate Vacuum...

Embodiment 2

[0020] A preparation method of a green high-adherence water-based antirust agent is characterized in that it comprises the following steps:

[0021] S1. Add ethylene glycol monobutyl ether and absolute ethanol to bisphenol A epoxy resin E-51, heat up to 90°C, stir to disperse the epoxy resin evenly, then add alanine and phenylalanine Sodium hydroxide aqueous solution of acid composite modifier, control the reaction temperature to 90°C, and the reaction time to 120min to obtain a modified water-based epoxy resin, wherein the molar ratio of alanine:phenylalanine:epoxy resin is 2: 1:2;

[0022] S2. Take eucalyptus leaves and add them to 85wt% ethanol to dissolve them, soak them at room temperature for 4 hours, then soak them in a constant temperature water bath at 65°C for 2 hours, use 85wt% ethanol solution to ultrasonically filter the residue for 2 hours, combine the two filtrates, rotary evaporate, add petroleum ether to degrease and remove color, concentrate in a vacuum drie...

Embodiment 3

[0026] A preparation method of a green high-adherence water-based antirust agent is characterized in that it comprises the following steps:

[0027] S1. Add ethylene glycol monobutyl ether and absolute ethanol to bisphenol A epoxy resin E-51, heat up to 85°C, stir to disperse the epoxy resin evenly, and then add alanine and phenylalanine Sodium hydroxide aqueous solution of acid compound modifier, control reaction temperature to 90°C, reaction time to 90min, obtain modified water-based epoxy resin, wherein the molar ratio of alanine:phenylalanine:epoxy resin is 2: 1.5:2;

[0028] S2. Take eucalyptus leaves and add them to 85wt% ethanol to dissolve them, soak them at room temperature for 3 hours, then soak them in a constant temperature water bath at 65°C for 3 hours, use 85wt% ethanol solution to ultrasonically filter the residue for 2 hours, combine the two filtrates, rotary evaporate, add petroleum ether to degrease and remove color, concentrate in a vacuum dried into eucal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com