Surgical robot passive joint based on motor drive locking

A surgical, motor-driven technology, applied in the fields of surgery, manipulators, medical science, etc., can solve the problems of complex design of hydraulically driven locking joints, difficult for medical robots, and easy leakage of hydraulic oil, which is conducive to robot system integration and easy maintenance. , to avoid the effect of easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

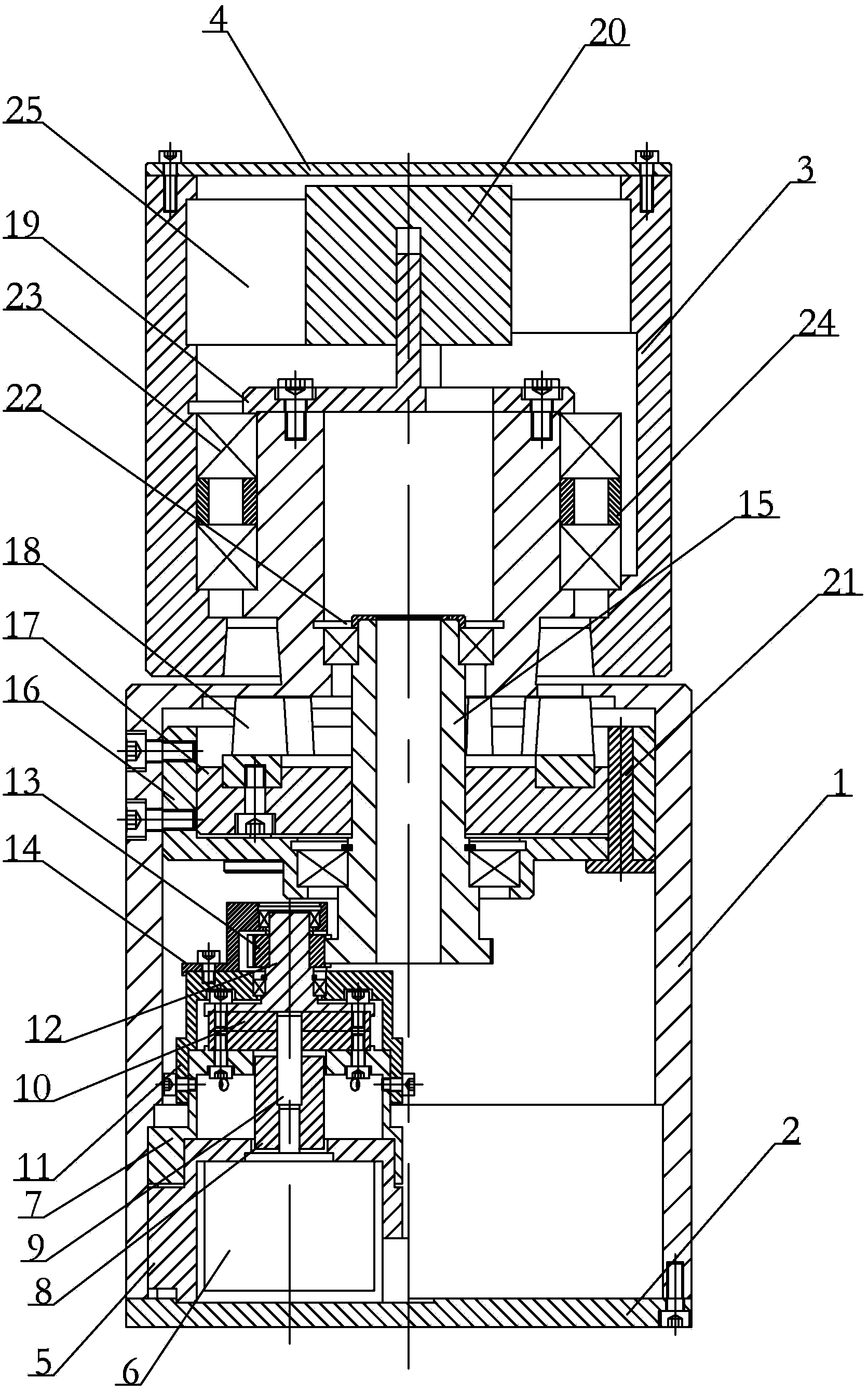

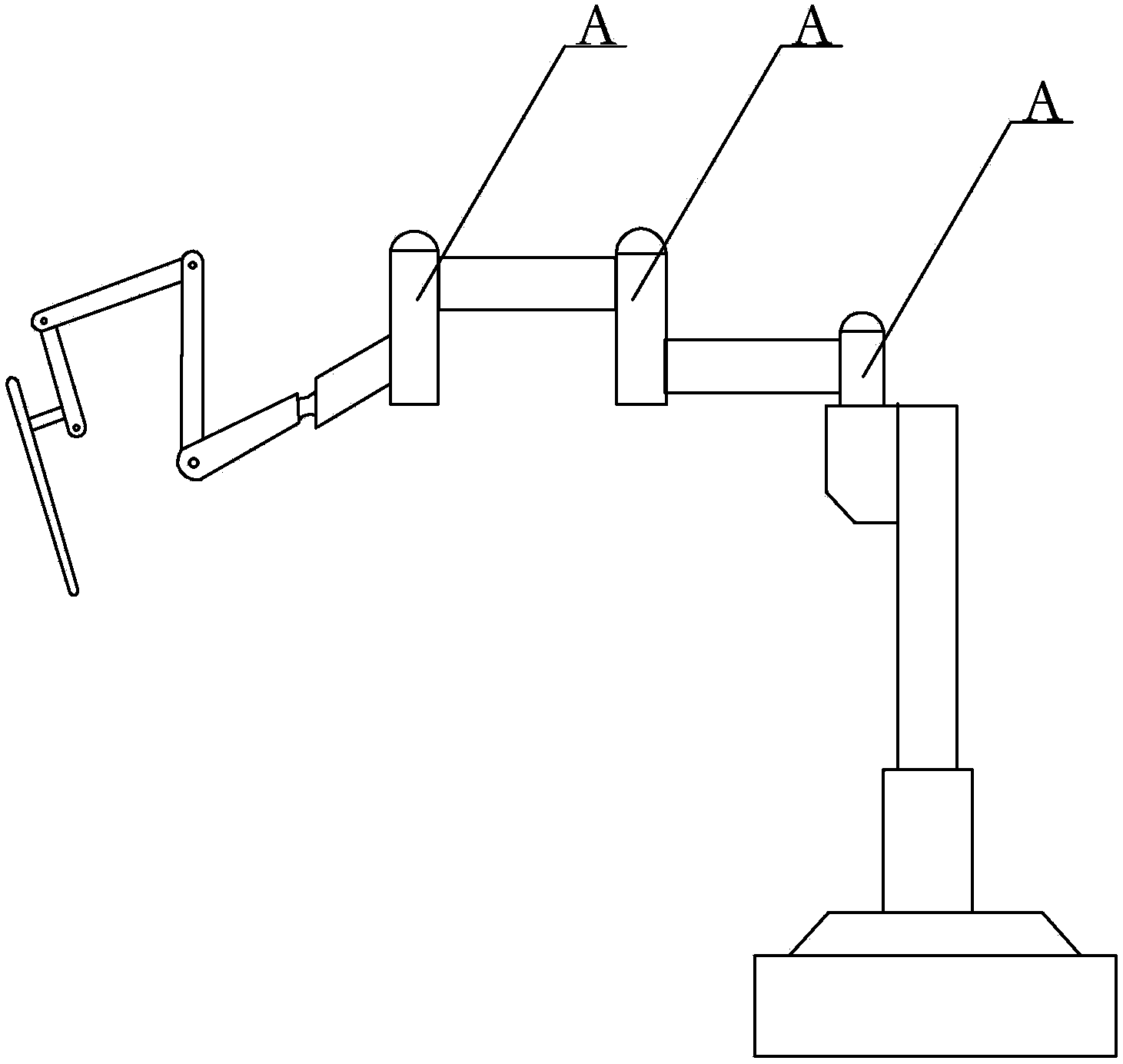

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a lower casing 1, a bottom plate 2, an upper casing 3, a top cover 4, a motor base 5, a stepping motor 6, a casing connector 7, an elastic coupling 8, and an input shaft 9 , Harmonic reducer 10, lower bearing housing 11, output shaft 12, gear 13, upper bearing housing 14, gear screw shaft 15, guide 16, support 17, wedge-shaped friction member 18, encoder shaft 19, The encoder 20 and the encoder connector 25, the bottom plate 2 is fixedly installed on the lower end of the lower case 1, the upper end of the lower case 1 is rotatably embedded in the lower part of the upper case 3, and the top cover 4 is fixedly installed on the upper case 3 The upper end of the motor seat 5 is fixedly installed in the lower housing 1, the stepping motor 6 is arranged in the motor seat 5, and the output end of the stepping motor 6 connects with the input shaft 9, the harmonic reducer 10 and...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 The present embodiment will be described. The gear screw shaft 15 of the present embodiment is a hollow gear screw shaft. Such setting realizes the internal wiring of the joint, which is beneficial to the integration of the robot system. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the passive joint of the surgical robot in this embodiment further includes a guide pin 21 , and the guide pin 21 is vertically arranged on the guide member 16 and the support member 17 . Such setting is convenient to provide guidance for the movement of the passive joint. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com