Production method of fish cartilage extract for preventing and treating osteoarthritis

A technology for osteoarthritis and production methods, applied in bone diseases, food science, drug combination, etc., can solve the problems of excessive molecular weight and low clinical bioavailability of chondroitin sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

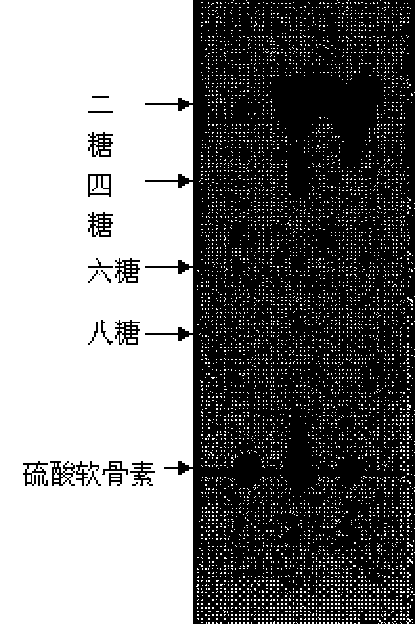

[0032] Wash the salmon cartilage, soak it in water for 2 hours, put it in a cooking pot and cook it at 100°C for 30 minutes, remove the fish meat and oil, wash it with water, chop it into pieces with a size of 1cm×1cm, and set aside; choose the processed Cartilage 500g, add water according to the ratio of material to liquid 1:2, adjust pH=7.0 with sodium hydroxide or hydrochloric acid, add papain 5g / kg, neutral protease 5g / kg and chondroitinase 5g / kg. Control the temperature at 45°C for enzymatic hydrolysis for 5 hours, raise the temperature of the obtained enzymatic hydrolyzate to 80°C for heat treatment for 15 minutes, then lower the temperature to 70°C, centrifuge for 40 minutes at a speed of 2000 r / min, and add an appropriate amount of filter aid kaolin to aid in filtration The obtained supernatant was intercepted by an ultrafiltration membrane with a molecular weight of 5000, and the membrane permeate was collected and spray-dried to obtain a cartilage extract.

[0033] T...

Embodiment 2

[0035] Wash the cartilage of the ray cartilage, soak it in water for 2 hours, put it in a cooking pot and cook it at 100°C for 30 minutes, remove the fish meat and oil, wash it with water, chop it into pieces with a size of 1cm×1cm, and set aside; For 500g of cartilage, add water according to the ratio of solid to liquid 1:2, adjust the pH=7.0 with sodium hydroxide or hydrochloric acid, add papain 5g / kg, neutral protease 10g / kg and chondroitinase 5g / kg. Control the temperature at 45°C for enzymolysis for 5 and 6 hours, raise the temperature of the obtained enzymolysis solution to 90°C for heat treatment for 13 minutes, then lower the temperature to 70°C, centrifuge for 30 minutes at a speed of 4000 r / min, and add an appropriate amount of filter aid diatom The supernatant obtained by soil filtration was intercepted by an ultrafiltration membrane with a molecular weight of 5000, and the membrane permeate was collected and spray-dried to obtain a cartilage extract.

[0036] The p...

Embodiment 3

[0038] Wash the shark cartilage, soak it in water for 2 hours, put it in a cooking pot and cook it at 100°C for 30 minutes, take it out, remove the fish meat and oil, rinse it with water, chop it into 1cm×1cm pieces, and set aside; choose the processed Cartilage 500g, add water according to the ratio of material to liquid 1:2, adjust pH=7.0 with sodium hydroxide or hydrochloric acid, add papain 5g / kg, neutral protease 5g / kg and chondroitinase 10g / kg. Control the temperature at 45°C for enzymolysis for 5 and 6 hours, raise the temperature of the obtained enzymolysis solution to 100°C for heat treatment for 10 minutes, then lower the temperature to 70°C, use 6000r / min speed, centrifuge for 15 minutes, add an appropriate amount of filter aid kaolin The supernatant obtained by the filtration aid was intercepted by an ultrafiltration membrane with a molecular weight of 5000, and the membrane permeate was collected and spray-dried to obtain a cartilage extract.

[0039] The prepared f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com