Preparation method of copper ion imprinted chitosan composite material

A composite material and chitosan technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of high energy consumption, easy pollution by electrolysis, and high treatment costs. Achieve the effect of low energy consumption, simple and easy operation, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

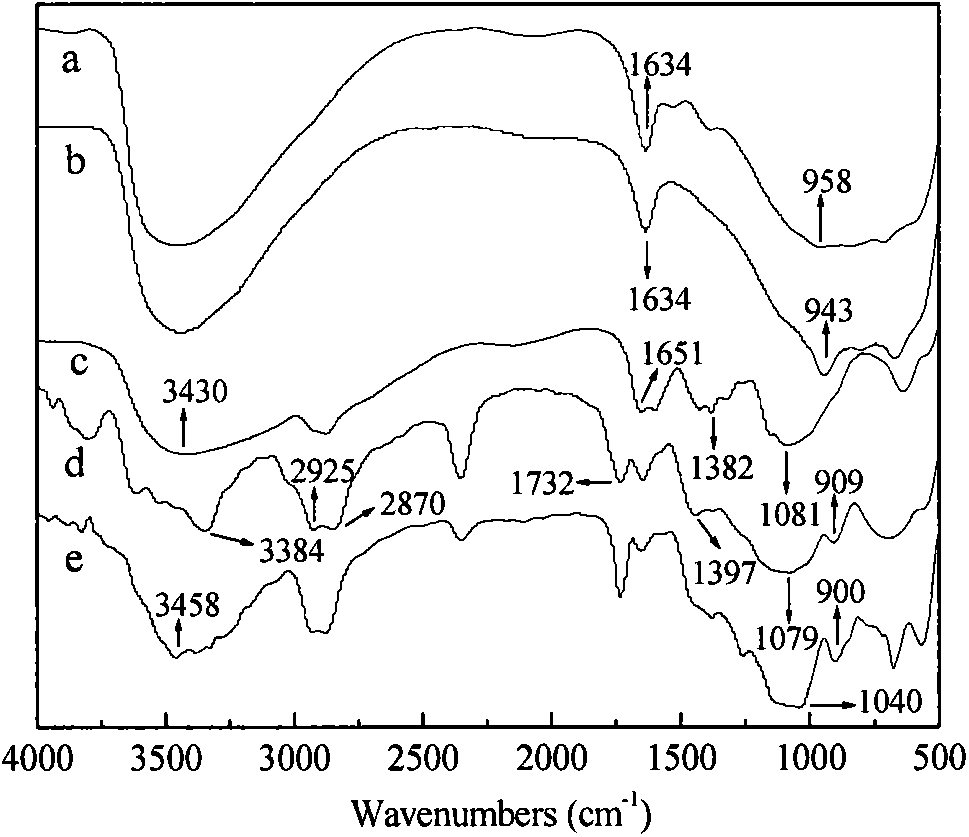

[0053] 1. Preparation of imprinted polymer

[0054] (1)Al 2 o 3 Surface active SiO 2 layer deposition

[0055] Weigh an appropriate amount of Al 2 o 3 Powder, soak in acetone for 10h. Treat with 3mol / L NaOH solution, wash with deionized water, filter and dry. The dried Al 2 o 3 Place in a crucible and bake in a muffle furnace at 600°C for 7h. After natural cooling, soak in dilute HCl for 15 hours, wash with deionized water until neutral, filter, and dry in a vacuum drying oven for later use; take a certain amount of the above-mentioned dried samples, add an appropriate amount of 1 / 10 TEOS / ethanol The solution was placed in a round bottom flask at 70°C for 30h under reflux, then the reacted sample was filtered, moved into a muffle furnace for calcination at 550°C for 3h, and cooled naturally. After washing with deionized water, add 0.1 mol / L HCl and soak for 24 hours to obtain active Si-OH. Finally, it was washed with deionized water until neutral, and dried at 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com