Zerovalent nano-iron coated polymethyl methacrylate and preparation method thereof

A technology of polymethyl methacrylate and zero-valent nano-iron, which is applied in the field of nanomaterial composites, can solve the problems of poor affinity, weak controllability and complex coating mechanism of inorganic nanoparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Put 4mL of methyl methacrylate and 0.0077g of azobisisobutyronitrile in a Schlenk tube, heat to 70°C for reaction, after 2 hours of reaction, add 10mL of tetrahydrofuran, then add 250mL of methanol for precipitation, filter and dry After drying, polymethyl methacrylate was obtained.

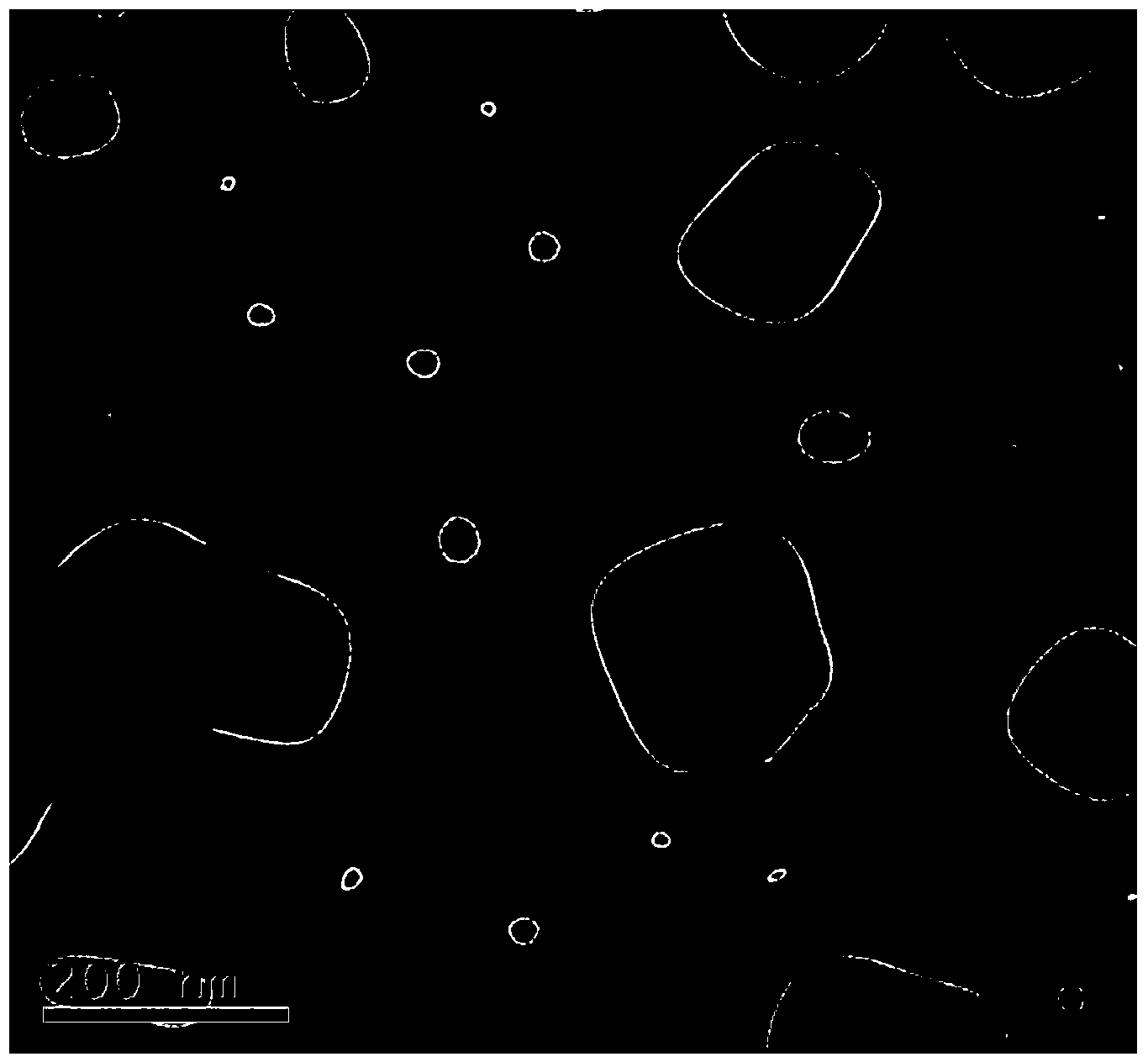

[0087] Put 1.15g of polymethyl methacrylate prepared above, 1.20g of ferrous chloride and 50mL of tetrahydrofuran into a 250mL three-necked flask, and place them in an ultrasonic cleaner. Under the protection of an inert gas and ultrasonic conditions, 22 mL of lithium triethylborohydride and 50 mL of tetrahydrofuran mixture were added dropwise to the three-necked flask. The dropwise addition time was 30 minutes, and the reaction was continued for 1 hour after the dropwise addition was completed. After the reaction is completed, add 500mL of ethanol to the three-neck flask for precipitation, and pour off the upper liquid. The obtained solid mixture is dissolved in 20mL of tetrahydrofuran an...

Embodiment 2

[0097] Put 4mL of methyl methacrylate and 0.0077g of azobisisobutyronitrile in a Schlenk tube, heat to 70°C for reaction, after 2 hours of reaction, add 10mL of tetrahydrofuran, then add 250mL of methanol for precipitation, filter and dry After drying, polymethyl methacrylate was obtained.

[0098] Put 1.15g of polymethyl methacrylate prepared above, 1.20g of ferrous chloride and 50mL of tetrahydrofuran into a 250mL three-necked flask, and place them in an ultrasonic cleaner. Under the protection of an inert gas and ultrasonic conditions, 22 mL of lithium triethylborohydride and 50 mL of tetrahydrofuran mixture were added dropwise to the three-necked flask. The dropwise addition time was 30 minutes, and the reaction was continued for 1 hour after the dropwise addition was completed. After the reaction is completed, add 500mL of ethanol to the three-neck flask for precipitation, and pour off the upper liquid. The obtained solid mixture is dissolved in 20mL of tetrahydrofuran an...

Embodiment 3

[0103] Put 4mL of methyl methacrylate and 0.0077g of azobisisobutyronitrile in a Schlenk tube, heat to 70°C for reaction, after 2 hours of reaction, add 10mL of tetrahydrofuran, then add 250mL of methanol for precipitation, filter and dry After drying, polymethyl methacrylate was obtained.

[0104] Put 2.30 g of polymethyl methacrylate prepared above, 1.20 g of ferrous chloride and 50 mL of tetrahydrofuran into a 250 mL three-necked flask, and place them in an ultrasonic cleaner. Under the protection of an inert gas and ultrasonic conditions, 22 mL of lithium triethylborohydride and 50 mL of tetrahydrofuran mixture were added dropwise to the three-necked flask. The dropwise addition time was 30 minutes, and the reaction was continued for 1 hour after the dropwise addition was completed. After the reaction is completed, add 500mL of ethanol to the three-neck flask for precipitation, and pour off the upper liquid. The obtained solid mixture is dissolved in 20mL of tetrahydrofura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com