Mesoporous composite material Fe3O4-Co3O4 and preparation method thereof, and application in degradation of gaseous pollutants

A fe3o4-co3o4, composite material technology, applied in metal/metal oxide/metal hydroxide catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of high cost, secondary air pollution, slow effect, etc. Achieve the effect of easy recovery, avoid pollution, and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mesoporous composite material Fe 3 o 4 -Co 3 o 4 preparation of

[0025] 1) 2.57g of cobalt nitrate hexahydrate and 2.02g of iron nitrate nonahydrate were respectively dissolved in 50mL of aqueous solution to obtain iron-containing solution and cobalt-containing solution respectively.

[0026] 2) Mix the iron-containing solution and the cobalt-containing solution obtained in step 1) evenly, adjust the concentration of the F127 aqueous solution to 0.06g / mL, pour 15mL of the F127 aqueous solution, and place the obtained sample in a dry box after fully stirring. Dry at 100°C for 10h.

[0027] 3) The dried sample was calcined in a muffle furnace under air conditions at a heating rate of 5°C / min and 400°C for 6h, and the calcined sample was cooled to room temperature and ground to obtain the mesoporous composite material Fe 3 o 4 -Co 3 o 4 .

[0028] (2) Detection

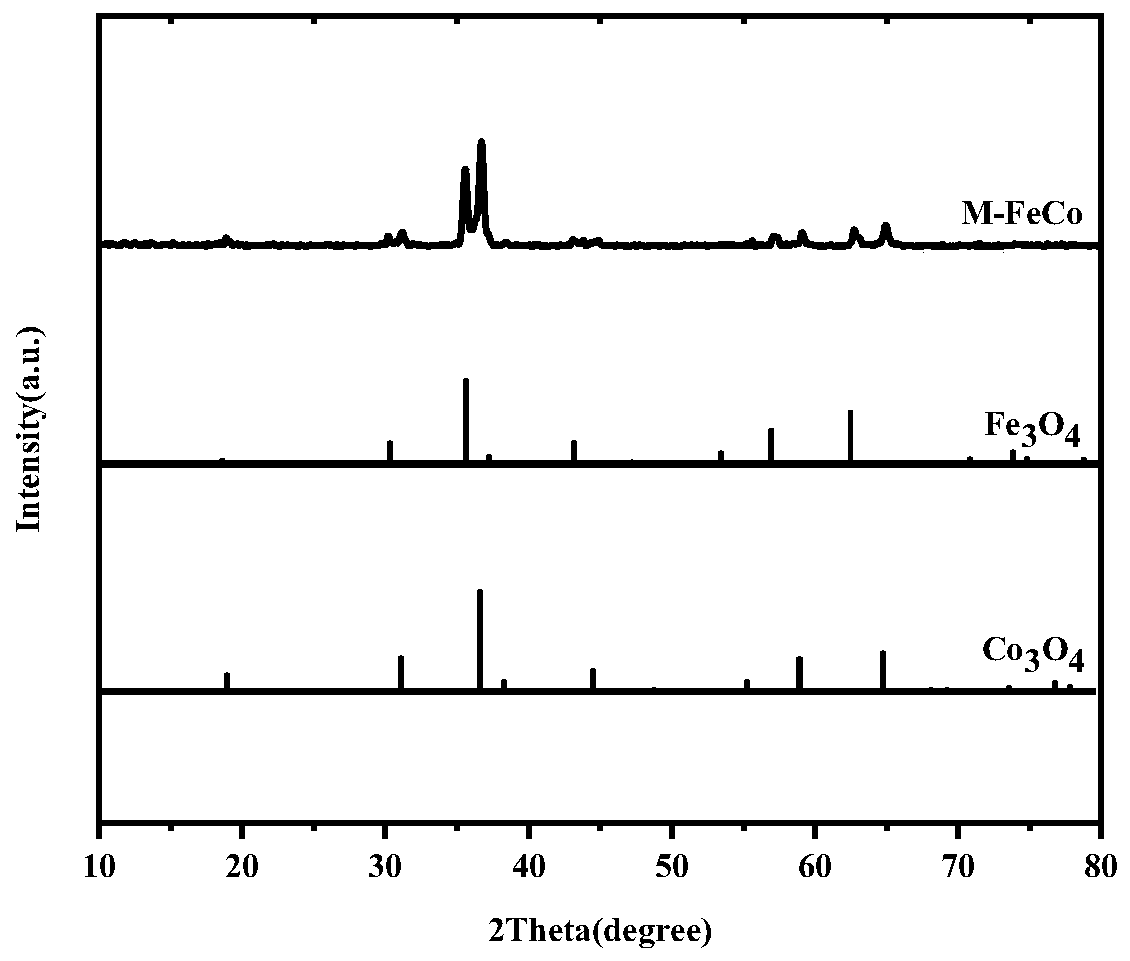

[0029] figure 1 for Co 3 o 4 , Fe 3 o 4 and the mesoporous composite Fe prepared in Example...

Embodiment 2

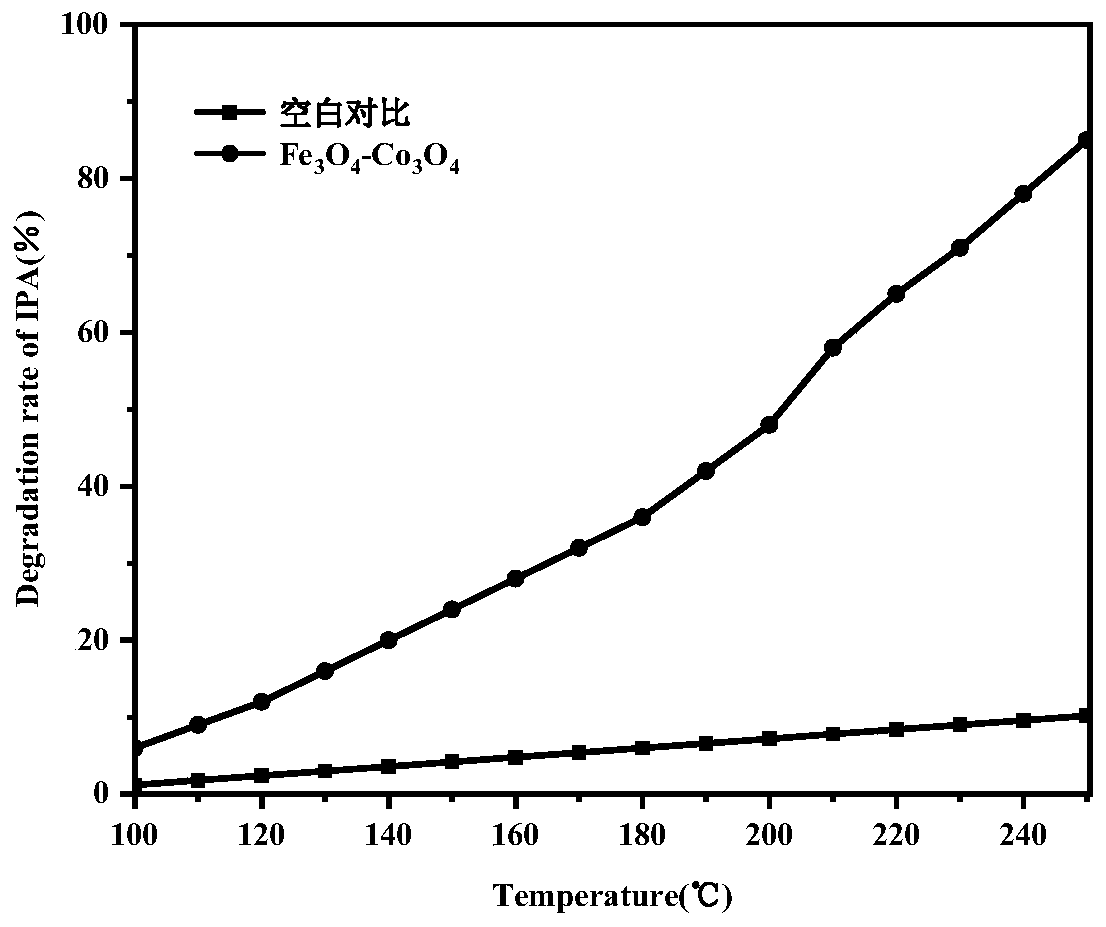

[0031]Example 2 mesoporous composite material Fe 3 o 4 -Co 3 o 4 Application as a catalyst in the degradation of gaseous isopropanol

[0032] Method: get 0.1 gram of the mesoporous composite material Fe prepared in Example 1 3 o 4 -Co 3 o 4 Put it into a heatable experimental device, and inject 5 μL of liquid isopropanol into the experimental device. After the isopropanol is fully vaporized, detect the gas concentration of isopropanol in the experimental device.

[0033] Comparative test: Inject 5 μL of liquid isopropanol directly into the heatable experimental device, and detect the gas concentration of isopropanol in the experimental device after the isopropanol is fully vaporized.

[0034] With the increase of temperature, the degradation rate of isopropanol gas in the experimental device was determined. Depend on image 3 As shown, the mesoporous composite Fe 3 o 4 -Co 3 o 4 The degradation rate to isopropanol increases gradually. When the temperature is 250°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com