Powder of an alloy based on uranium and molybdenum in gamma-metastable phase, composition of powders comprising this powder, and uses of said powder and composition

A composition, metastable phase technology, applied in the powder field of alloys, which can solve problems such as uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

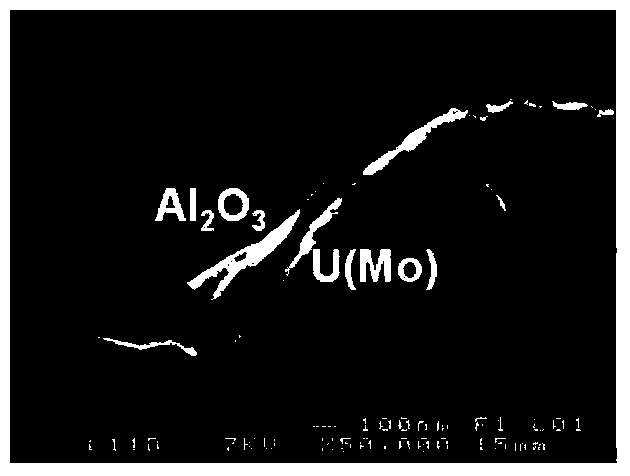

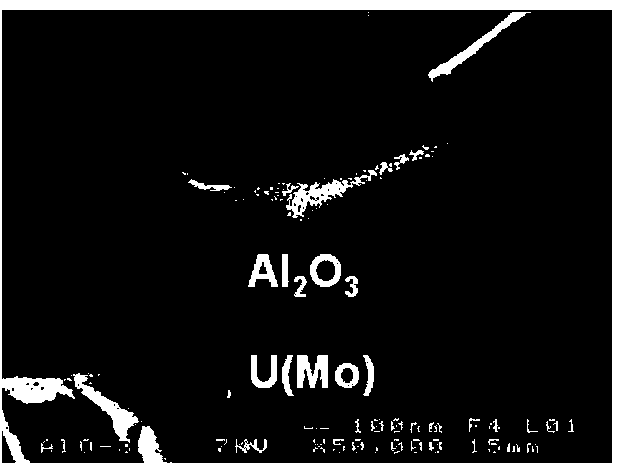

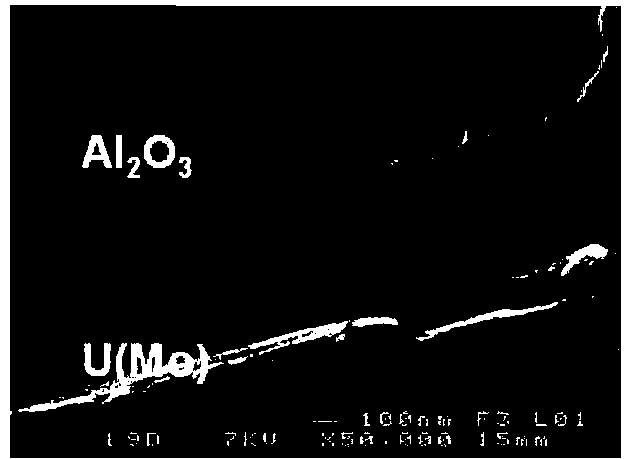

[0060] Example 1: Deposition of an aluminum oxide layer on a solid substrate made of γ-U(8Mo) alloy

[0061] By pulsed laser deposition technology, an aluminum oxide layer with a thickness of about 50nm, 100nm or 400nm is deposited on a substrate with a measured length of 4±0.5mm, a width of 4±0.5mm and a thickness of 1±0.5mm, and the substrate is made of An alloy of uranium and molybdenum (8% molybdenum by mass) in the γ-metastable phase (γ-U(8Mo)).

[0062] As this technique is well known, it is only briefly recalled that it involves bombardment, a vacuum box, a target consisting of the material to be deposited with a pulsed laser beam. When the laser power density is high enough, a certain amount of material is ejected from the target perpendicular to the surface and deposited on the substrate, which may have been heated and placed relative to the target.

[0063] In the present case, the target used was an aluminum target and the pressure in the box was 10 -6 On the orde...

Embodiment 2

[0072] Example 2: Chemical reactivity of a solid substrate made of γ-U(8Mo) alloy covered with an aluminum oxide layer in the presence of aluminum or Al(7Si) alloy

[0073] As described in Example 1 above, in the case of diffusion pairs activated by heat treatment, first, in the presence of aluminum, the chemical reaction of a substrate made of γ-U(8Mo) alloy already covered with a layer of aluminum oxide was tested Second, in the presence of an alloy (Al(7Si)) of aluminum and silicon (7% silicon by mass), the substrate made of γ-U(8Mo) alloy, which has been covered with an aluminum oxide layer, was tested for chemical reactivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com