Method for waterproof construction using a heat-blocking composition for a paint-film waterproofing technique and using a fiber sheet manufactured using a stitch-bonding technique

A fiber sheet and construction method technology, applied in chemical instruments and methods, roofing using flexible materials, building structures, etc., can solve the problems of complex construction methods, reduced weather resistance, loss of reliability of waterproof layer thickness, etc. Saving carbon dioxide production, good UV and weather resistance, non-flammable self-extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Advantages and features of the present invention, and methods for realizing them, will become apparent with reference to the accompanying drawings and the detailed description of the embodiments described below.

[0040] However, the present invention is not limited to the following embodiments, but is realized in various forms different from each other, and this embodiment only makes the disclosure of the present invention more complete, and has common knowledge in the technical field of the present invention The skilled person provides the full scope of the invention, and the scope of the invention is defined by the claims.

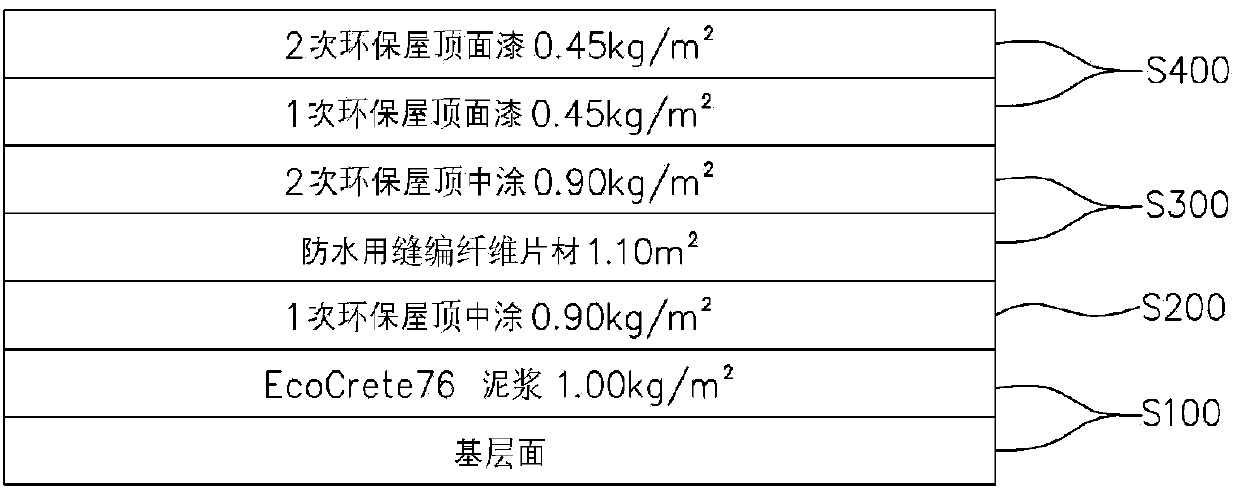

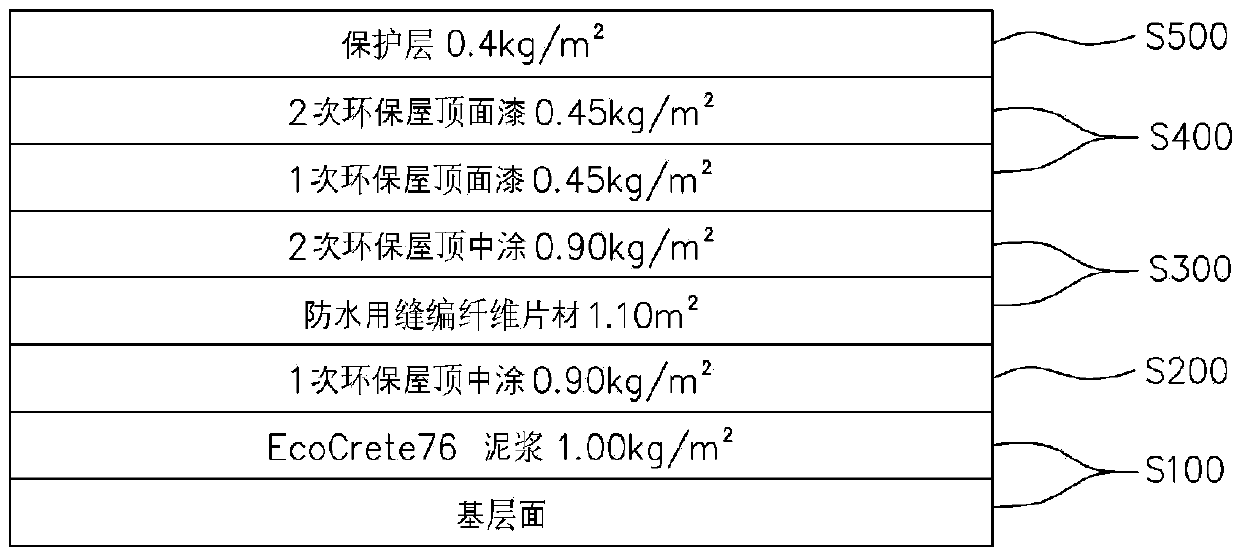

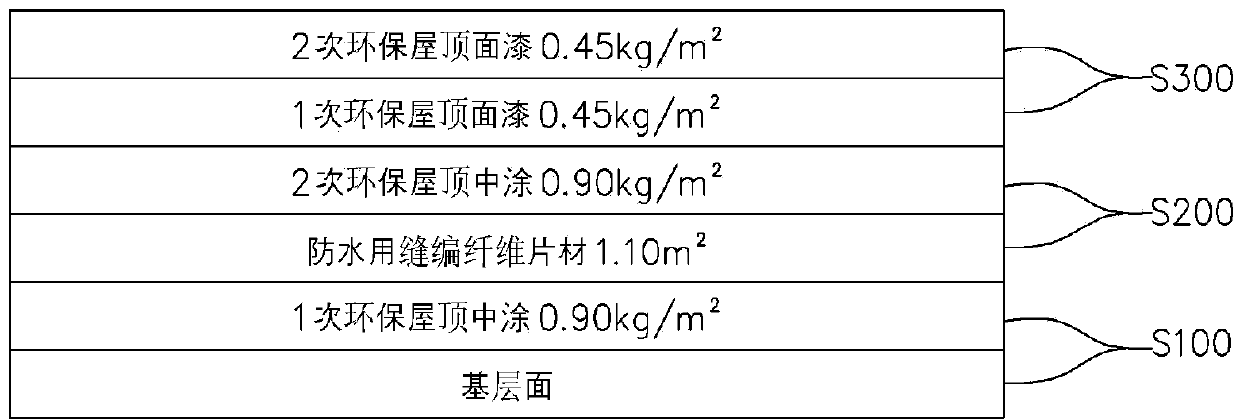

[0041] The present invention relates to a composition using a coating waterproof method with heat-insulating performance and a method of waterproofing a fiber sheet produced by a stitch-bonded method, respectively applicable to an exposed method exposed to the outside and a non-exposed method not exposed to the outside.

[0042] Here, the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com