Stable PGE1 lyophilized emulsion and preparation method thereof

A freeze-dried milk, stabilized technology, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

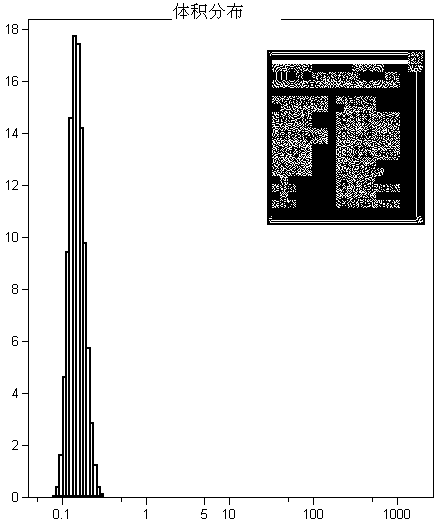

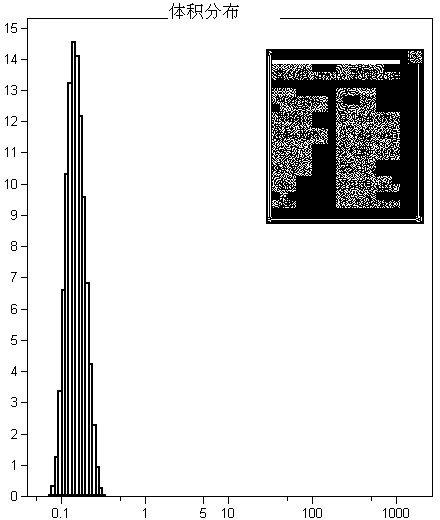

Image

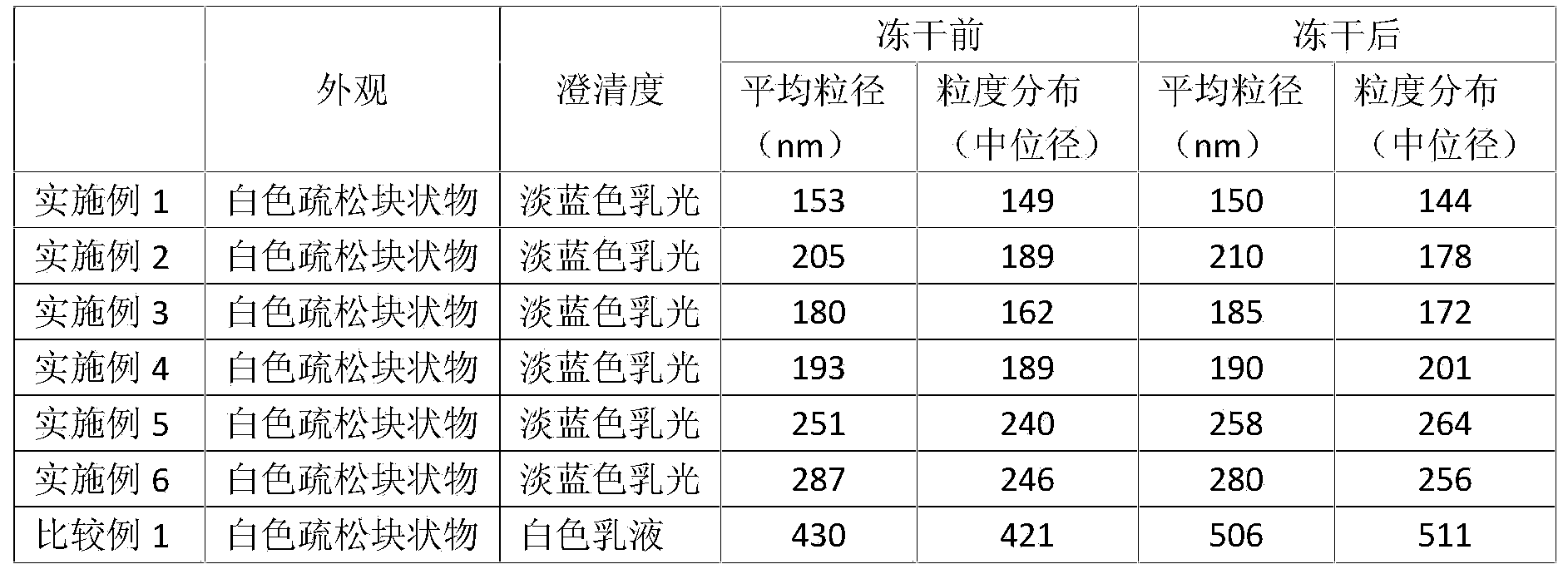

Examples

Embodiment 1

[0032] Weigh 10g of soybean lecithin and 20g of glycerin into a beaker, add 400ml of purified water, and shear and stir at 15,000rpm for 5 minutes to form a water phase; weigh 60g of soybean oil into a beaker, and add 5mg of PGE1 and 50mg of vitamin E while heating and dissolving in water at 60°C while stirring , Stir to disperse evenly to form an oil phase. Slowly drop the water phase into the oil phase under low-speed stirring. After adding completely, shear and stir at 10,000 rpm for 5 minutes to obtain colostrum, adjust the pH to 8 with sodium hydroxide; homogenize the colostrum solution through a high-pressure milk homogenizer, 100bar, 8 laps of homogenization under high pressure of 1000bar to obtain a fine emulsified emulsion; weigh 50g of refined sucrose into a beaker, add 300ml of purified water, stir, dissolve, and set the volume to 400ml after the dissolution is complete; after the above prepared fine emulsification Mix the emulsion and the solution prepared from ref...

Embodiment 2

[0034]Weigh 15g of egg yolk phospholipids and 25g of glycerin into a beaker, add 400ml of purified water, and shear and stir at 15,000rpm for 5 minutes to form a water phase; weigh 80g of soybean oil into a beaker, heat and dissolve in water at 60°C while stirring, add 5mg of PGE1 and 200mg of vitamin E , Stir to disperse evenly to form an oil phase. Slowly drop the water phase into the oil phase under low-speed stirring. After adding completely, shear and stir at 10,000 rpm for 5 minutes to obtain colostrum, adjust the pH to 8 with sodium hydroxide; homogenize the colostrum solution through a high-pressure milk homogenizer, 100bar, 8 laps of homogenization under high pressure 1000bar to obtain a fine emulsified emulsion; weigh 150g of refined sucrose into a beaker, add 300ml of purified water, stir, dissolve, and set the volume to 400ml after the dissolution is complete; after the above prepared fine emulsification Mix the emulsion and the solution prepared from refined sucro...

Embodiment 3

[0036] Weigh 20g of soybean lecithin and 40g of glycerin into a beaker, add 400ml of purified water, and shear and stir at 15,000rpm for 5 minutes to form a water phase; weigh 70g of soybean oil into a beaker, heat and dissolve in water at 60°C while stirring, add 5mg of PGE1 and 300mg of vitamin E , Stir to disperse evenly to form an oil phase. Slowly drop the water phase into the oil phase under low-speed stirring. After adding completely, shear and stir at 10,000 rpm for 5 minutes to obtain colostrum, adjust the pH to 8 with sodium hydroxide; homogenize the colostrum solution through a high-pressure milk homogenizer, 100bar, 8 laps of homogenization under high pressure of 1000bar to obtain a refined emulsified emulsion; weigh 100g of glucose and 100g of refined sucrose into a beaker, add 300ml of purified water, stir, dissolve, and set the volume to 400ml after the dissolution is complete; Mix the refined emulsified emulsion with the solution made from refined sucrose, set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com