Desulfurization packed tower of marine diesel engine

A technology for marine diesel engines and packed towers, applied in the direction of using liquid separation agents, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as equipment blockages in packed towers, and achieve the goals of preventing equipment blockages, reducing exhaust gas temperature, and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

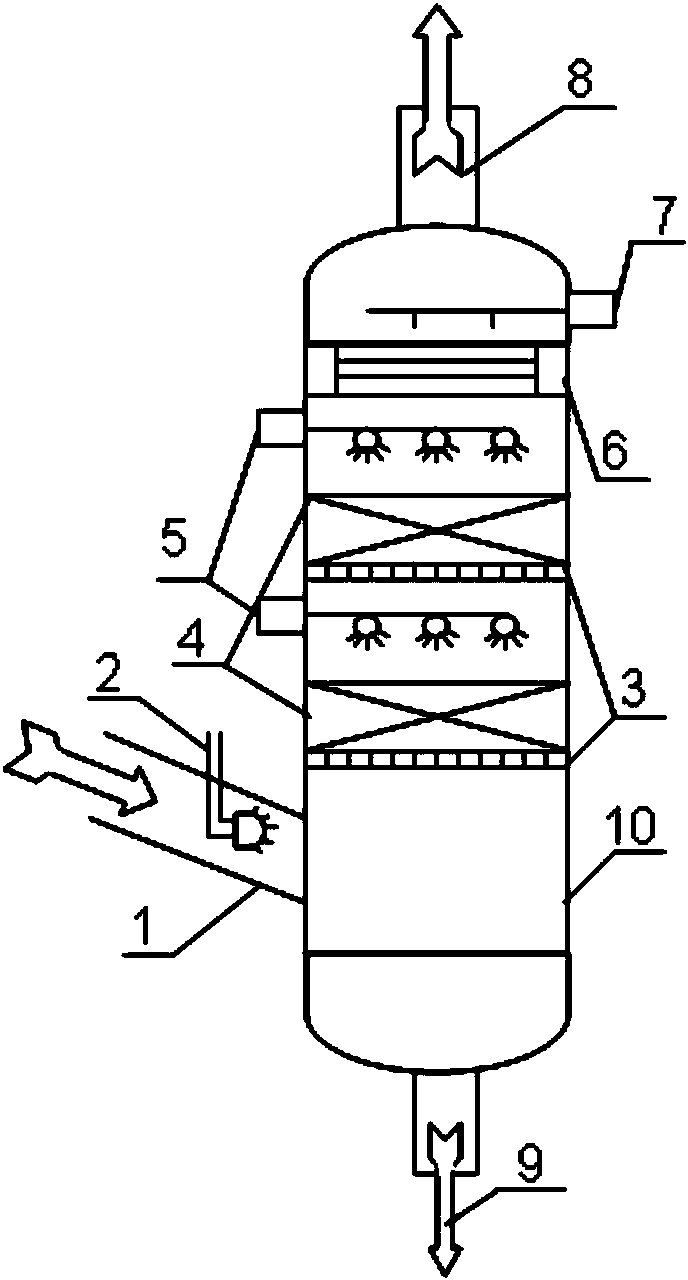

[0016] combine figure 1 , the present invention includes an air inlet 1, a washing liquid pre-spray device 2, a support grid 3, a packing layer 4, a high-temperature spray system 5, a demister 6, a cleaning system 7, a waste gas outlet 8, a waste liquid outlet 9, For the packed tower body 10, a washing liquid pre-spraying device 2 is added in the inlet duct 1 of the packed tower 10, and the inlet duct 1 of the packed tower 10 is arranged in a downward slope. The washing liquid pre-spraying device 2 adopts a nozzle type liquid sprayer. The nozzle-type liquid sprayer is installed on the upper end of the inlet channel, and the inlet channel 1 of the packed tower 10 adopts a downward inclined setting. The spraying direction of the nozzle-type liquid shower is along the direction of the flue, and after the sprayed washing liquid fully contacts with the exhaust gas fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com