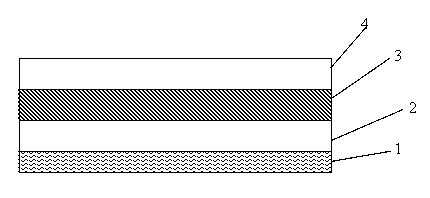

Thermal transfer printing conductive film for radio-frequency identification tag antenna

A technology of radio frequency identification tags and conductive films, which is applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as unstable conductivity, affecting antenna stability, complex process, etc., and achieve fineness High, good hot stamping adhesion effect, conductive and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of release layer coating solution:

[0037] Desmolux® XP2740 8.0 servings

[0038] Nano silica modified acrylate resin 15.0 parts

[0039] Dipentaerythritol hexaacrylate 30.0 parts

[0040] 184 3.0 copies

[0041] Fumed silica (particle size 1 micron) 6.5 parts

[0042] Tech-6300 1.0 copies

[0043] EFKA 3777 0.5 parts

[0044] Butanone 10.0 parts

[0045] Ethyl acetate 20.0 parts.

[0046] Add methyl ethyl ketone and ethyl acetate into the container, and then add the above-mentioned other components sequentially under stirring state, and after fully stirring and mixing, the release layer coating liquid is obtained.

[0047] On the surface of the PET base material with a thickness of 12 microns, the above-mentioned release layer coating solution is coated, with a thickness of 3 microns, then vacuum-plated silver on the release layer, with a thickness of 150 nm, and then coated with a conductive adhesive layer with a thickness of 2 microns to obtain T...

Embodiment 2

[0050] Preparation of release layer coating solution:

[0051]Desmolux® XP2738 16.0 parts

[0052] Nano silica modified acrylate resin 10.0 parts

[0053] Dipentaerythritol hexaacrylate 20 parts

[0054] 184 1.0 copies

[0055] Fumed silica (particle size 1 micron) 3.0 parts

[0056] Tech-6300 0.6 parts

[0057] EFKA 3777 0.4 parts

[0058] Butanone 25 parts

[0059] 32 parts of ethyl acetate.

[0060] Add methyl ethyl ketone and ethyl acetate into the container, and then add the above-mentioned other components sequentially under stirring state, and after fully stirring and mixing, the release layer coating liquid is obtained.

[0061] On the surface of the PET base material with a thickness of 11 microns, apply the above-mentioned release layer coating solution with a thickness of 2 microns, then vacuum copper plating on the release layer with a thickness of 150 nm, and then coat a conductive adhesive layer with a thickness of 2 microns to obtain Thermal transfe...

Embodiment 3

[0064] Preparation of release layer coating solution:

[0065] Desmolux® XP2740 10.0 servings

[0066] Nano silica modified acrylate resin 12.0 parts

[0067] Dipentaerythritol hexaacrylate 20 parts

[0068] 1173 1.5 copies

[0069] Fumed silica (particle size 1 micron) 4.0 parts

[0070] Tech-6300 1.5 parts

[0071] EFKA 3777 0.5 parts

[0072] Butanone 25 parts

[0073] 25 parts of ethyl acetate.

[0074] Add methyl ethyl ketone and ethyl acetate into the container, and then add the above-mentioned other components sequentially under stirring state, and after fully stirring and mixing, the release layer coating liquid is obtained.

[0075] On the surface of the PET base material with a thickness of 11 microns, the above-mentioned release layer coating solution is coated, with a thickness of 2.5 microns, and then vacuum copper plating on the release layer, with a thickness of 180nm, and then coated with a thickness of 4 microns. Conductive adhesive layer, obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com