Method for preparing ferulic acid from wheat bran by using two-enzyme method

A technology of wheat bran and ferulic acid, applied in the field of bioengineering, can solve problems such as the difficulty of separating ferulic acid, and achieve the effect of short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Double Enzyme Extraction of Ferulic Acid in Wheat Bran

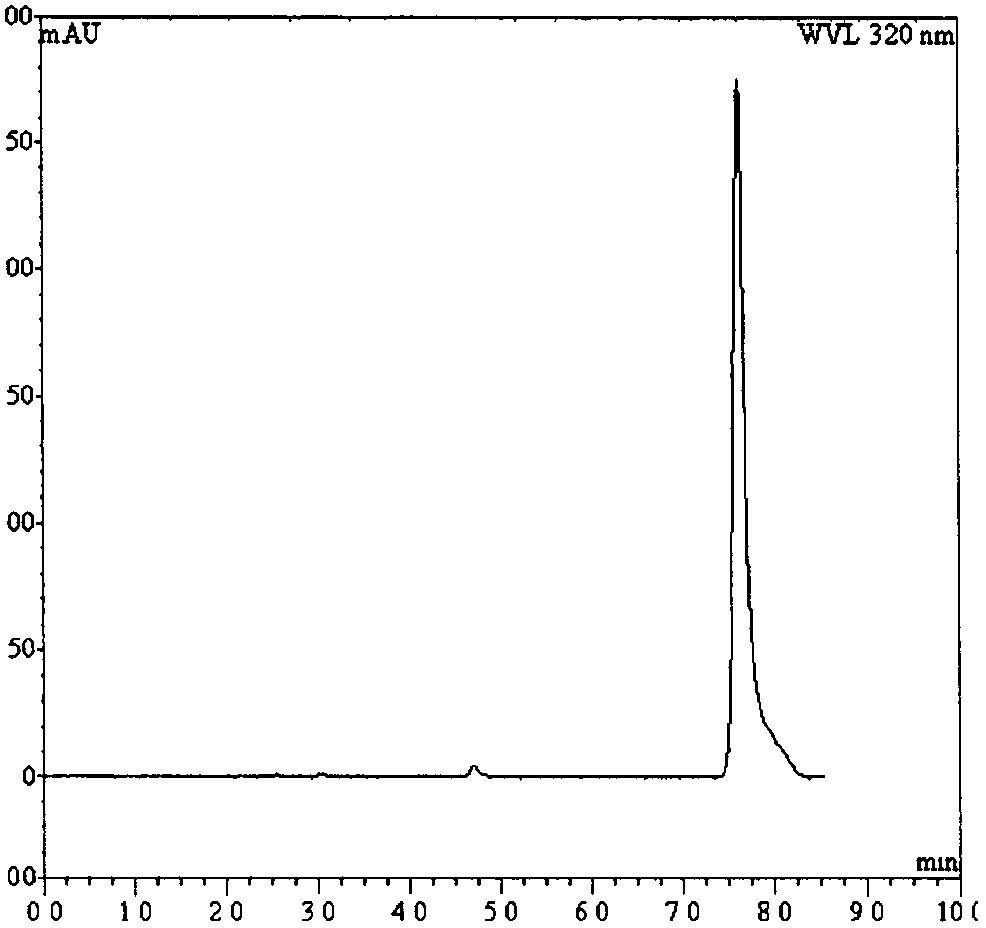

[0020] Accurately weigh 0.5g of wheat bran and place it in a 100mL Erlenmeyer flask. Add 8mL reAorFaeA enzyme solution (about 16.88U) and 0.5mL reAorXynllA enzyme solution (about 72.5515U), dilute to 30mL with 0.1mmol / L, pH 5.0 phosphate buffer, enzymolyze at 40°C for 10h, boil for 5min Inactivate the enzyme activity, centrifuge and collect the supernatant as the ferulic acid crude extract, the crude extract is concentrated to 1mL by rotary evaporation, and vacuum dried to obtain the ferulic acid crude extract powder, weighing 1.75g, detected by HPLC, ferulic acid The content is 0.13%.

Embodiment 2

[0021] Embodiment 2 macroporous resin purifies ferulic acid crude extract

[0022] Concentrate the crude extract of ferulic acid until the mass concentration of ferulic acid is 0.1 mg / mL, adjust the pH of the concentrated solution to 4.0, select HPD-300 macroporous resin, and pack 20 mL of resin into a column by wet method. After dynamic adsorption of 100mL of the crude extract on the column at 1mL / min, let stand for 2h, wash the column with water until the effluent is colorless, elute with 100mL of 50% ethanol at a flow rate of 1mL / min, and concentrate the eluent to 1mL by rotary evaporation. Vacuum dried into powder, weighing 431mg, detected by HPLC, the content of ferulic acid was 22.5%, and the recovery rate was 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com