Method for efficiently preparing hydrogen and nano silver

A hydrogen and nano technology, which is applied to the fields of hydrogen production and nanomaterial preparation, can solve the problems of low yield of nano-Ag, difficult agglomeration of nanoparticles and subsequent separation, and cannot be used as a means of hydrogen production. The process is simple and easy to implement, and the effect of easy industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

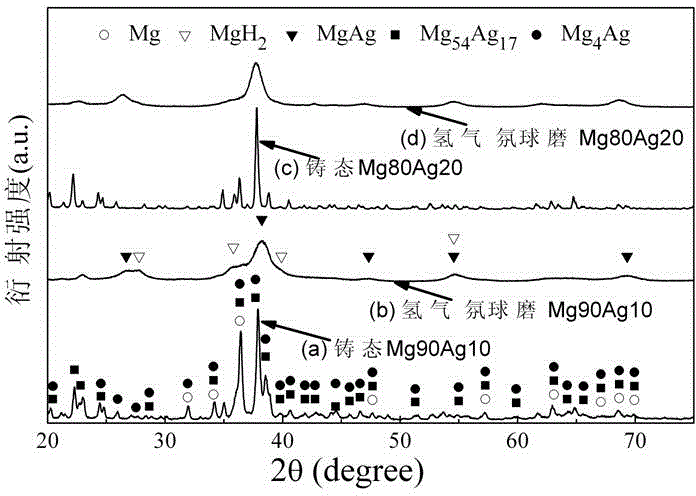

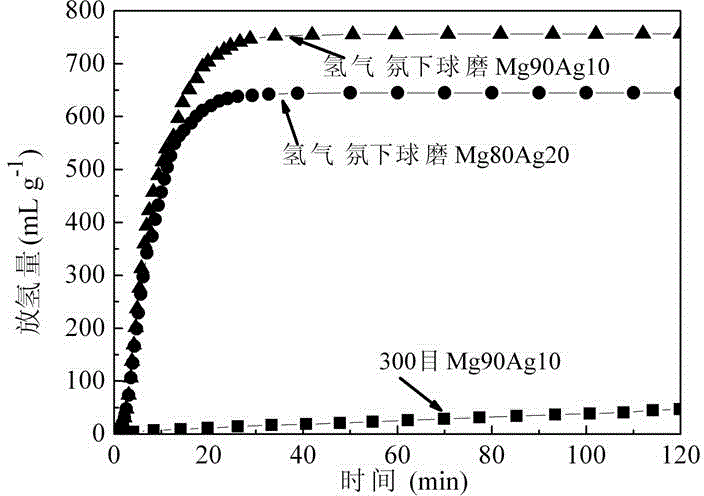

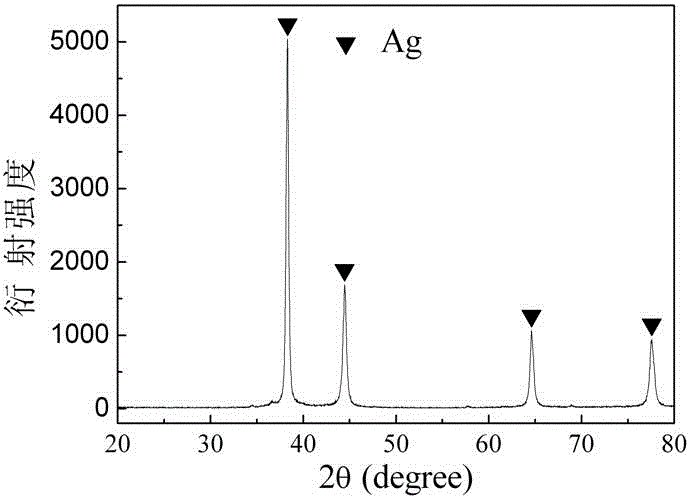

[0023] The total weight of the smelted alloy is about 100 grams, and the Mg block (purity 99%) and Ag flakes (purity 99.5%) are weighed according to the composition of Mg90Ag10. Put the weighed Mg block and Ag sheet into a copper crucible and induce melting at a power of 15 KW to obtain a Mg-Ag binary alloy, which is composed of Mg 4 Ag, Mg 54 Ag 17 and Mg composition (eg figure 1 (a)). Use a grinder to remove the oxide skin on the surface of the smelted alloy, and then grind it into a 100-mesh alloy powder in a glove box. The alloy powder is ball-milled in a ball mill tank filled with 5 atm hydrogen for 20 h to obtain nanocrystalline MgH 2 and MgAg and nano-state or disordered amorphous state of the original composition phase without hydrogenation decomposition (such as figure 1 (b)); where the ball-to-material ratio is 20:1, and the speed of the ball mill is 400 rpm. The alloy powder after ball milling was directly used as the preparation of H 2 And nano Ag materials...

Embodiment 2

[0025] The total weight of the smelted alloy is about 100 grams, and the Mg block (purity 99%) and Ag flakes (purity 99.5%) are weighed according to the composition of Mg80Ag20. Put the weighed Mg block and Ag sheet into a copper crucible and induce melting at a power of 15 KW to obtain a Mg-Ag binary alloy, which is composed of Mg 4 Ag, Mg 54 Ag 17 and a small amount of Mg (such as figure 1 (c)). Use a grinder to remove the oxide skin on the surface of the smelted alloy, and then grind it into a 100-mesh alloy powder in a glove box. The alloy powder is ball-milled in a ball mill tank filled with 5 atm hydrogen for 20 h to obtain nanocrystalline MgH 2 and MgAg and nano-state or disordered amorphous state of the original composition phase without hydrogenation decomposition (such as figure 1 (d)); where the ball-to-material ratio is 20:1, and the speed of the ball mill is 400 rpm. The alloy powder after ball milling was directly used as the preparation of H 2 And nano Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com