Single crystal furnace heat shield and preparation method thereof

A heat shield and single crystal furnace technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of affecting the quality of crystal growth, high processing cost of tungsten cylinder, expensive manufacturing cost, etc., to reduce Enterprise operating cost, good compactness and thermal stability, and excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

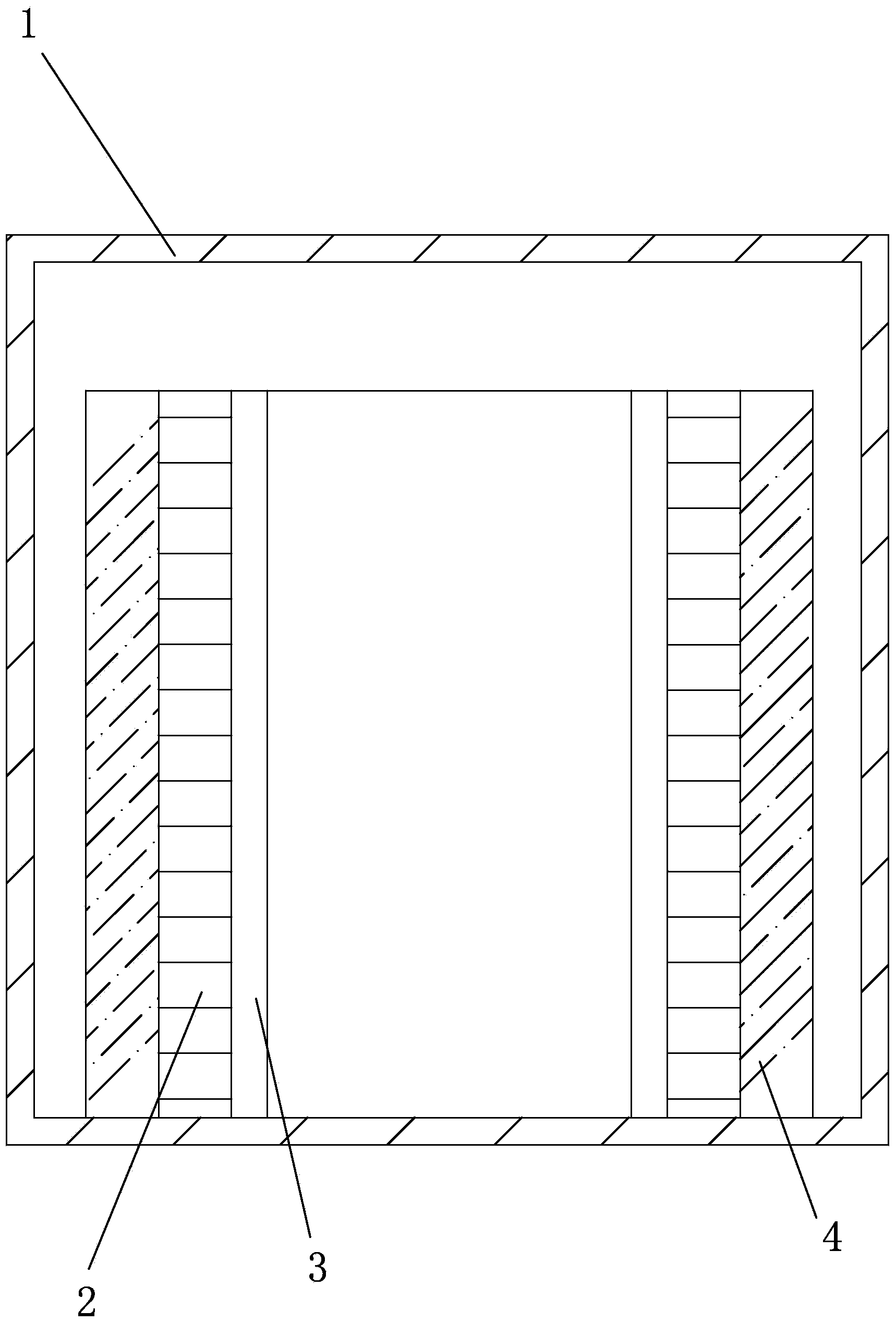

[0036] like figure 1 The shown heat shield of a single crystal furnace of the present invention comprises a furnace body 1, a zirconia ceramic insulation bucket 2 is arranged in the furnace body 1, and a nano-tungsten film layer is coated on the inner wall of the insulation bucket 2 3. A thin-walled molybdenum cylinder 4 is provided on the outer wall of the zirconia ceramic insulation barrel 2 .

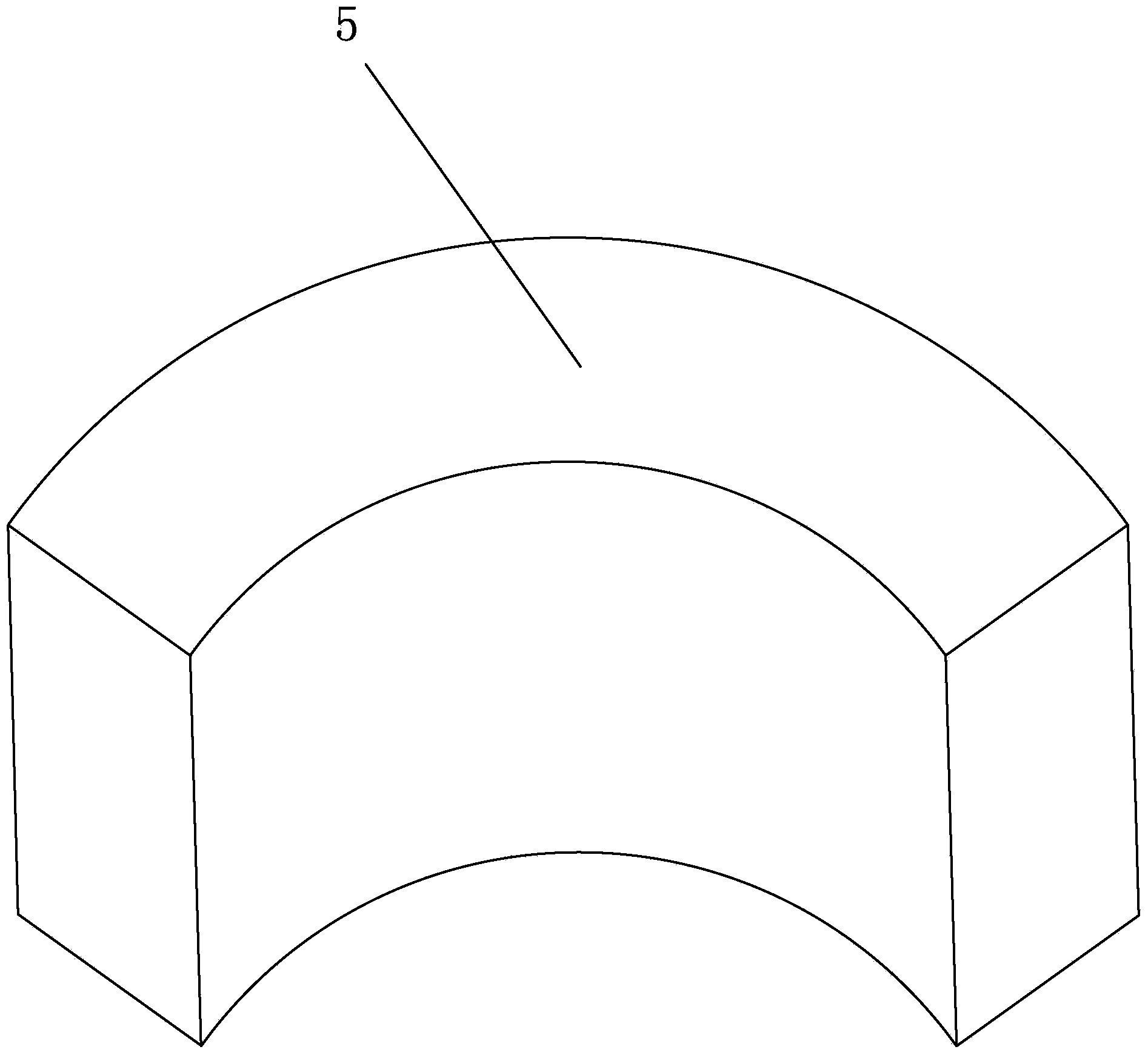

[0037] The zirconia ceramic insulation bucket 2 described in the present invention is formed by stacking several arc-shaped zirconia ceramic bricks 5 . The structure of the arc-shaped zirconia ceramic tile 5 is as figure 2 shown. The arc-shaped zirconia ceramic bricks described therein are doped with 3% Y by zirconia powder 2 o 3 The powder is compacted and sintered at high temperature. The thickness of the arc-shaped zirconia ceramic tile 5 is 40mm.

[0038] The nano-tungsten film layer 3 described in the present invention is plated on the inner wall of the heat preservation ...

Embodiment 2

[0048] like figure 1 The shown heat shield of a single crystal furnace of the present invention comprises a furnace body 1, a zirconia ceramic insulation bucket 2 is arranged in the furnace body 1, and a nano-tungsten film layer is coated on the inner wall of the insulation bucket 2 3. A thin-walled molybdenum cylinder 4 is provided on the outer wall of the zirconia ceramic insulation barrel 2 .

[0049] The zirconia ceramic insulation bucket 2 described in the present invention is formed by stacking several arc-shaped zirconia ceramic bricks 5 . The structure of the arc-shaped zirconia ceramic tile 5 is as figure 2 shown. The arc-shaped zirconia ceramic brick 5 is made of zirconia powder doped with 3% Y 2 o 3 The powder is compacted and sintered at high temperature. The thickness of the arc-shaped zirconia ceramic tile 5 is 50 mm.

[0050] The nano-tungsten film layer 3 described in the present invention is plated on the inner wall of the heat preservation barrel 2 by ...

Embodiment 3

[0060] like figure 1 The shown heat shield of a single crystal furnace of the present invention comprises a furnace body 1, a zirconia ceramic insulation bucket 2 is arranged in the furnace body 1, and a nano-tungsten film layer is coated on the inner wall of the insulation bucket 2 3. A thin-walled molybdenum cylinder 4 is provided on the outer wall of the zirconia ceramic insulation barrel 2 .

[0061] The zirconia ceramic insulation bucket 2 described in the present invention is formed by stacking several arc-shaped zirconia ceramic bricks 5 . The structure of the arc-shaped zirconia ceramic tile 5 is as figure 2 shown. The arc-shaped zirconia ceramic brick 5 is made of zirconia powder doped with 3% Y 2 o 3 The powder is compacted and sintered at high temperature. The thickness of the arc-shaped zirconia ceramic brick is 60mm.

[0062] The nano-tungsten film layer 3 described in the present invention is plated on the inner wall of the heat preservation barrel 2 by ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com