Combined type energy-saving biomass fuel boiler

A biomass fuel and combined technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve problems such as inability to adapt, and achieve the effects of reducing equipment investment costs, reducing pollution, and saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

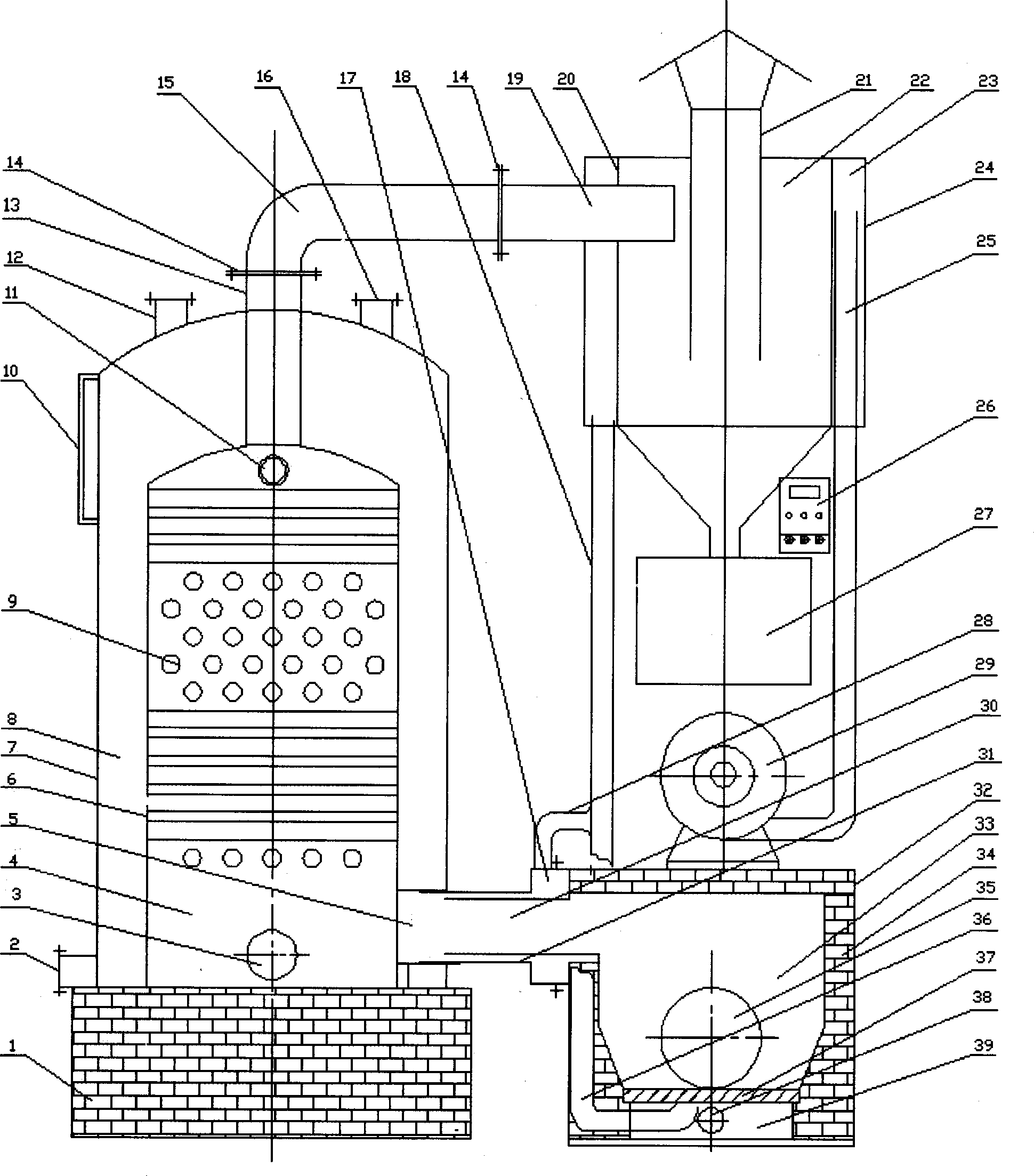

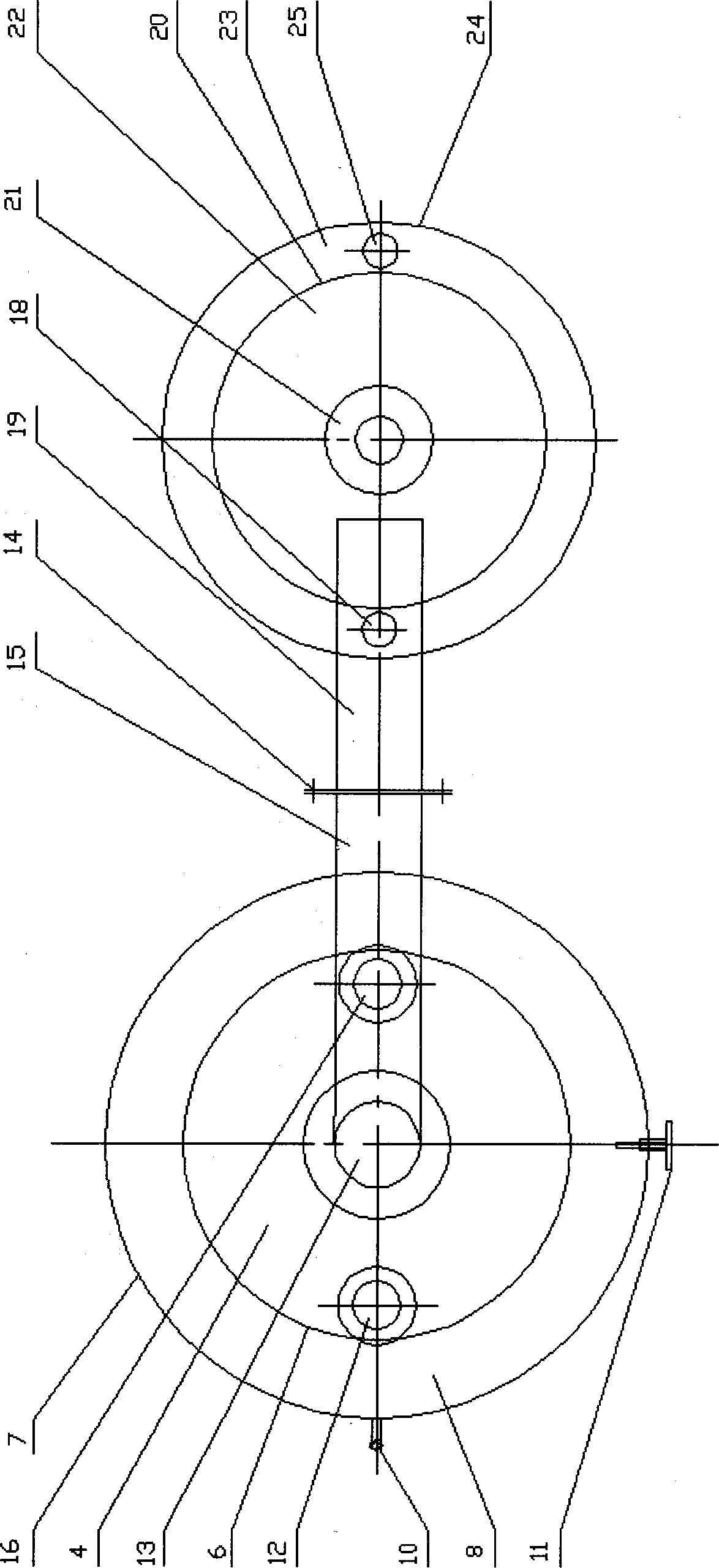

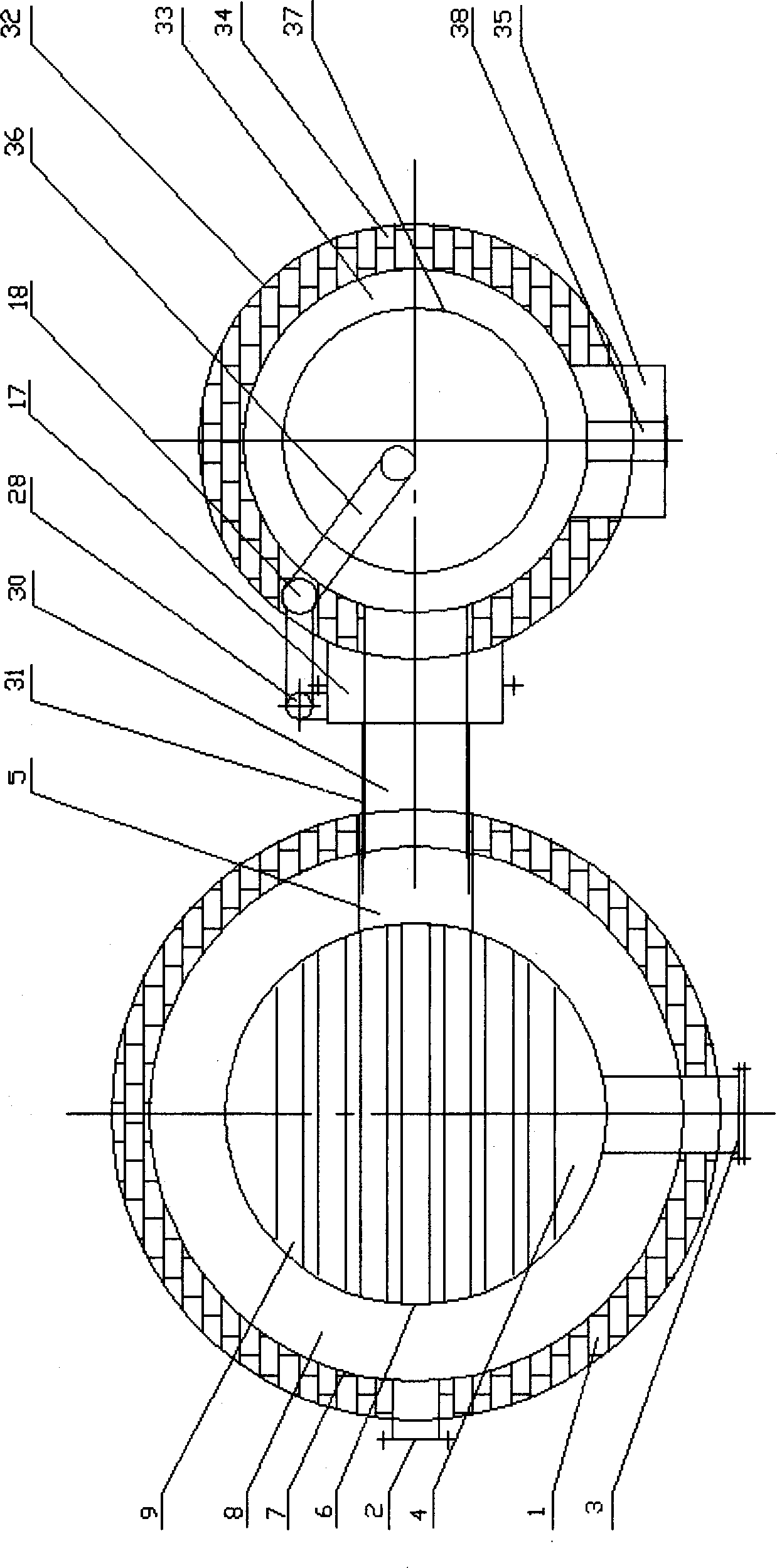

[0021] according to Figure 1-Figure 3 As shown, the present invention mainly includes: a boiler base 1, an outlet 2, a fire viewing port 3, a furnace chamber 4, a fire inlet 5, a furnace gall 6, a furnace shell 7, a boiler box 8, a heat-absorbing pipe 9, and a liquid level gauge 10 , thermometer 11, atmospheric communication pipe 12, boiler chimney 13, flange 14, connecting smoke pipe 15, atmospheric communication pipe 16, second oxygen supply chamber 17, waste heat main air duct 18, dust collector chimney inlet 19;

[0022] Waste heat dust collector 20, dust collector chimney 21, dust removal chamber 22, waste heat chamber 23, waste heat box 24, air inlet pipe 25, controller 26, dust box 27, second waste heat distribution pipe 28, blower 29;

[0023] Flame nozzle 30, flame nozzle 31, burner 32, burner furnace 33, burner refractory material 34, feeding port 35, first residual heat distribution duct 36, fire grate 37, soot cleaning port 38, first oxygen supply chamber 39.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com