High temperature resistance electronic device raw material and application thereof

A technology of electronic devices and raw materials, applied in the field of semiconductor materials, can solve the problems of device heat accumulation and temperature rise, deterioration of device electrical parameters, poor thermal conductivity of silicon dioxide, etc., and achieve stable threshold voltage and junction leakage current Effect of small, high breakdown electric field and electron saturation drift velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

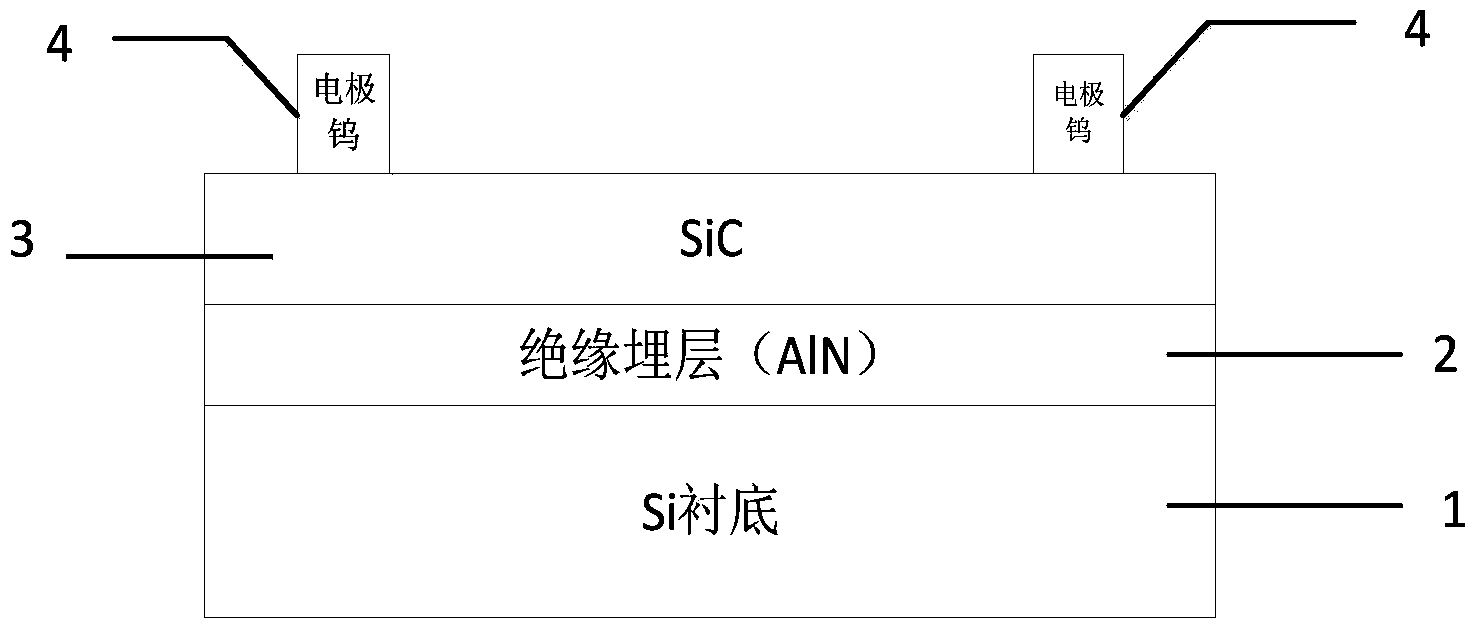

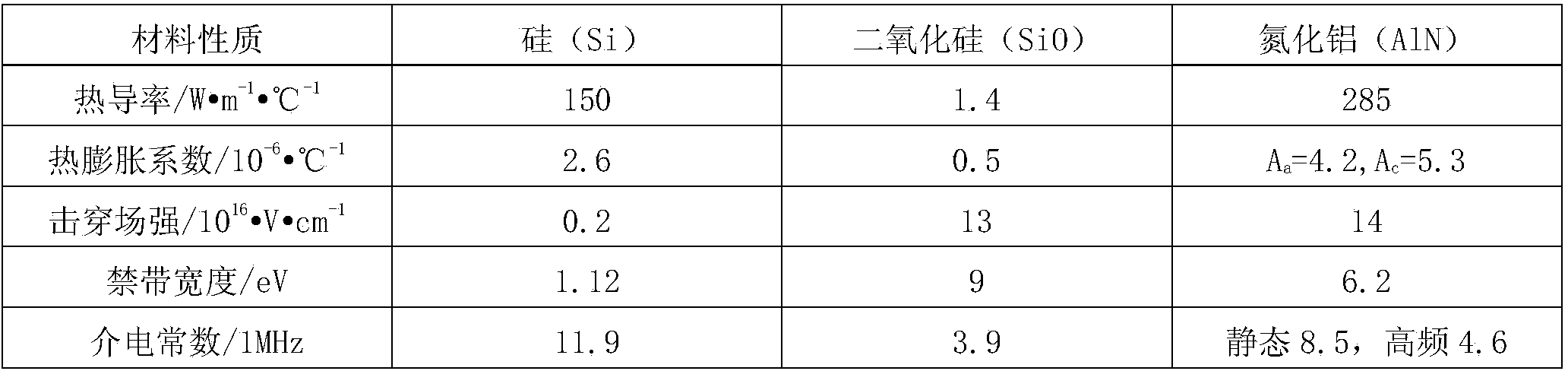

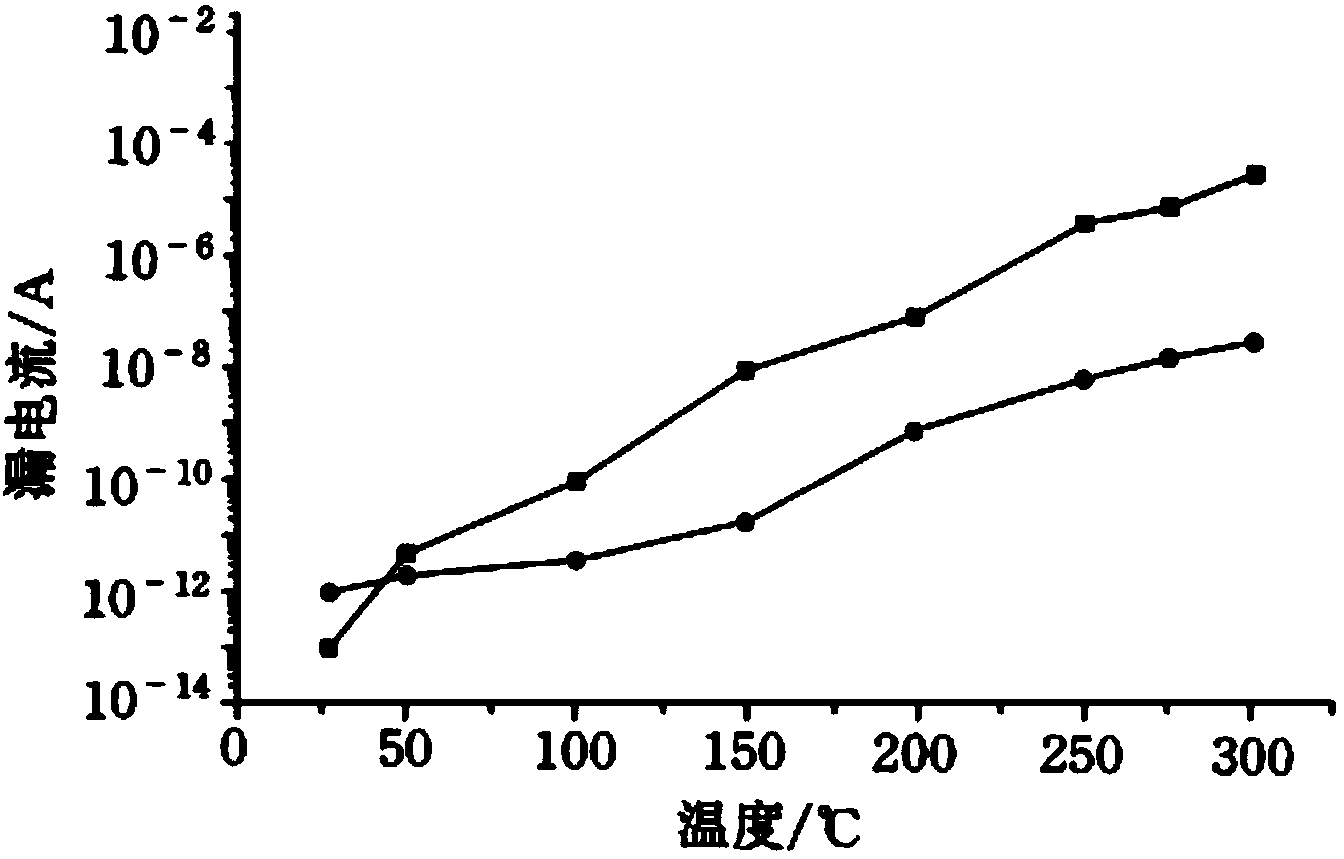

[0036] like figure 1 , figure 2 , Figure 5 and Image 6 As shown, a high temperature resistant electronic device material, the structure of the electronic device material includes a substrate layer 1, an insulating buried layer 2, a conductor layer 3 and an electrode 4, wherein the insulating buried layer 2 is arranged on the upper surface of the substrate layer 1, and the conductor The layer 3 is arranged on the upper surface of the insulating buried layer 2, the electrode 4 is arranged on the upper surface of the conductive layer, the material used for the substrate layer 1 is Si, the material used for the insulating buried layer 2 is AlN, and the material used for the conductive layer 3 is SiC. The material used for the motor 4 is tungsten, the thickness of the substrate layer is 1um, the thickness of the insulating buried layer is 0.1um, and the thickness of the conductor layer is 0.1um. figure 2 It shows that the material used for the insulating buried layer is AlN, S...

Embodiment 2

[0038] like figure 1 , Figure 5 and Image 6 As shown, a high temperature resistant electronic device material, its structure is as shown in Example 1, the difference is that the thickness of the conductor layer 3 is 0.3um.

Embodiment 3

[0040] like figure 1 , Figure 5 and Image 6 As shown, a high temperature resistant electronic device material, its structure is as shown in Example 1, the difference is that the thickness of the conductor layer 3 is 0.15um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com