Mutton saline ham pickling liquid and application thereof

A technology for pickling liquid and mutton, which is applied in the field of food engineering, can solve the problems that the processing technology cannot meet the requirements of modern production, and the difficulty of removing the smell of mutton, etc., and achieve good application prospects, improve immunity, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

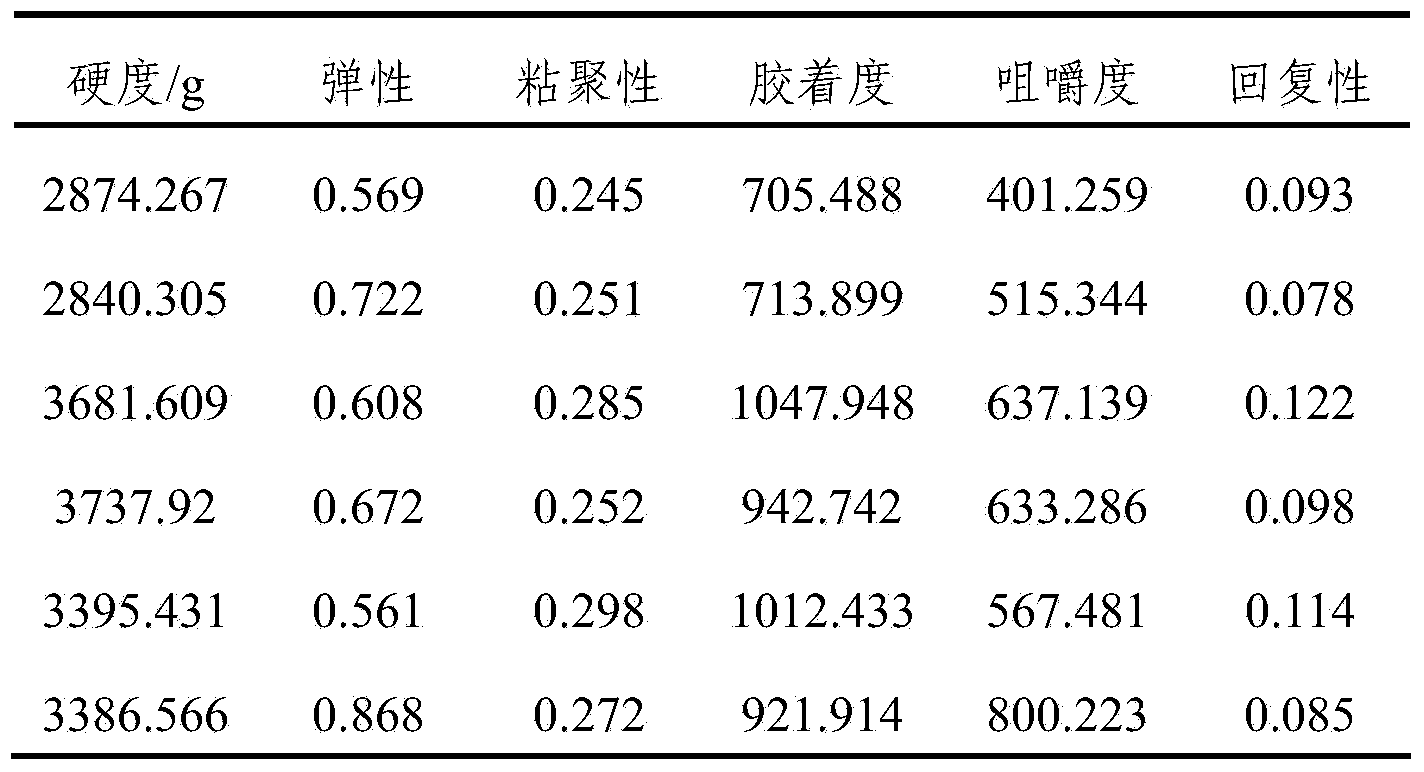

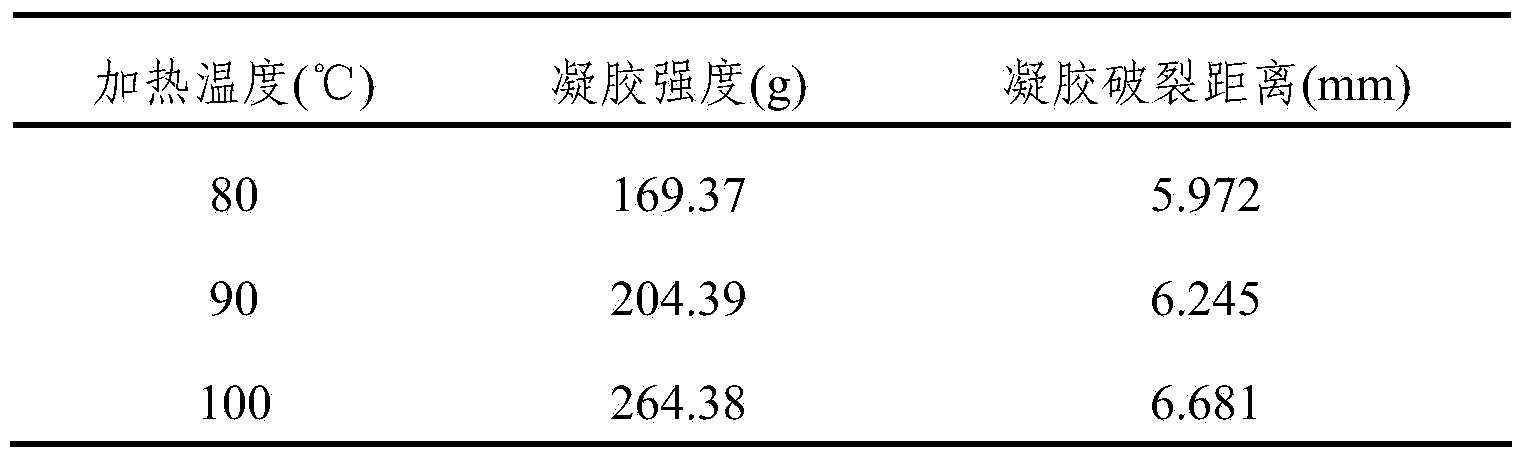

Embodiment 1

[0020] Embodiment 1 mutton brine ham pickling solution and its preparation

[0021] Weigh 1.2g sodium nitrite, 10g sodium erythorbate, 35g compound phosphate, 400g soybean protein isolate, 600g corn starch, 40g curdlan, 340g table salt, 180g white sugar, 60g xylose, 240g monosodium glutamate, 12g white pepper powder , Yuguo powder 10g, licorice powder 80g, ginger powder 12g, Monascus red pigment 20g, ice water 5kg. Put ice water into the blender, add soy protein isolate, stir well, add complex phosphate aqueous solution, mix well, then add salt, nitrite, stir well, then add sugar, xylose, curdlan , monosodium glutamate, white pepper powder, and jade fruit powder are mixed evenly, then add sodium erythorbate, then add cornstarch and stir evenly, and finally add monascus red pigment, stir evenly, and refrigerate for later use.

Embodiment 2

[0022] Embodiment 2 mutton brine ham pickling solution and its preparation

[0023] Weigh 1.2g sodium nitrite, 10g sodium erythorbate, 35g compound phosphate, 400g soybean protein isolate, 600g corn starch, 60g curdlan, 340g table salt, 180g white sugar, 50g xylose, 240g monosodium glutamate, 12g white pepper powder , Yuguo powder 10g, licorice powder 80g, ginger powder 10g, Monascus red pigment 20g, ice water 5kg. Put ice water into the blender, add soy protein isolate, stir well, add complex phosphate aqueous solution, mix well, then add salt, nitrite, stir well, then add sugar, xylose, curdlan , monosodium glutamate, white pepper powder, and jade fruit powder are mixed evenly, then add sodium erythorbate, then add cornstarch and stir evenly, and finally add monascus red pigment, stir evenly, and refrigerate for later use.

Embodiment 3

[0024] Embodiment 3 mutton brine ham pickling solution and its preparation

[0025] Weigh 1.2g sodium nitrite, 10g sodium erythorbate, 35g compound phosphate, 400g soybean protein isolate, 600kg corn starch, 80g curdlan, 340g table salt, 180g white sugar, 80g xylose, 240g monosodium glutamate, 12g white pepper powder , Yuguo powder 10g, licorice powder 80g, ginger powder 8g, monascus red pigment 20g, ice water 5kg. Put ice water into the blender, add soy protein isolate, stir well, add complex phosphate aqueous solution, mix well, then add salt, nitrite, stir well, then add sugar, xylose, curdlan , monosodium glutamate, white pepper powder, and jade fruit powder are mixed evenly, then add sodium erythorbate, then add cornstarch and stir evenly, and finally add monascus red pigment, stir evenly, and refrigerate for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com