Ultra-deep hydrogen desulfurization multi-metal body catalyst with a stratified structure as well as preparation method and application thereof

A bulk catalyst, layered structure technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, heterogeneous catalyst chemical elements, etc., can solve environmental unfriendly, environmental pollution, catalyst ratio problems such as small surface area and pore volume, to achieve the effect of high hydrodesulfurization activity, cost reduction, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the present invention is briefly described as follows:

[0048] a) Co-precipitating an aqueous solution of a soluble salt of a Group VIII metal and an aqueous solution of a soluble salt of a +2-valent metal to synthesize a catalyst precursor with a layered structure;

[0049] b) performing anion exchange reaction on the layered structure catalyst precursor slurry and the soluble salt containing at least two VIB group metal anion groups in a mixed solution of surfactant, water and organic solvent.

[0050] In detail, the preparation method of the present invention comprises the following steps:

[0051] a) adding a soluble salt of a VIII group metal and a soluble salt of a +2-valent metal into water to prepare a mixed aqueous solution of soluble salts, then dissolving the alkaline precipitating agent in water to form a solution, and finally adding the alkaline The precipitating agent is added to the mixed aqueous solution of the above-mentioned...

Embodiment 1

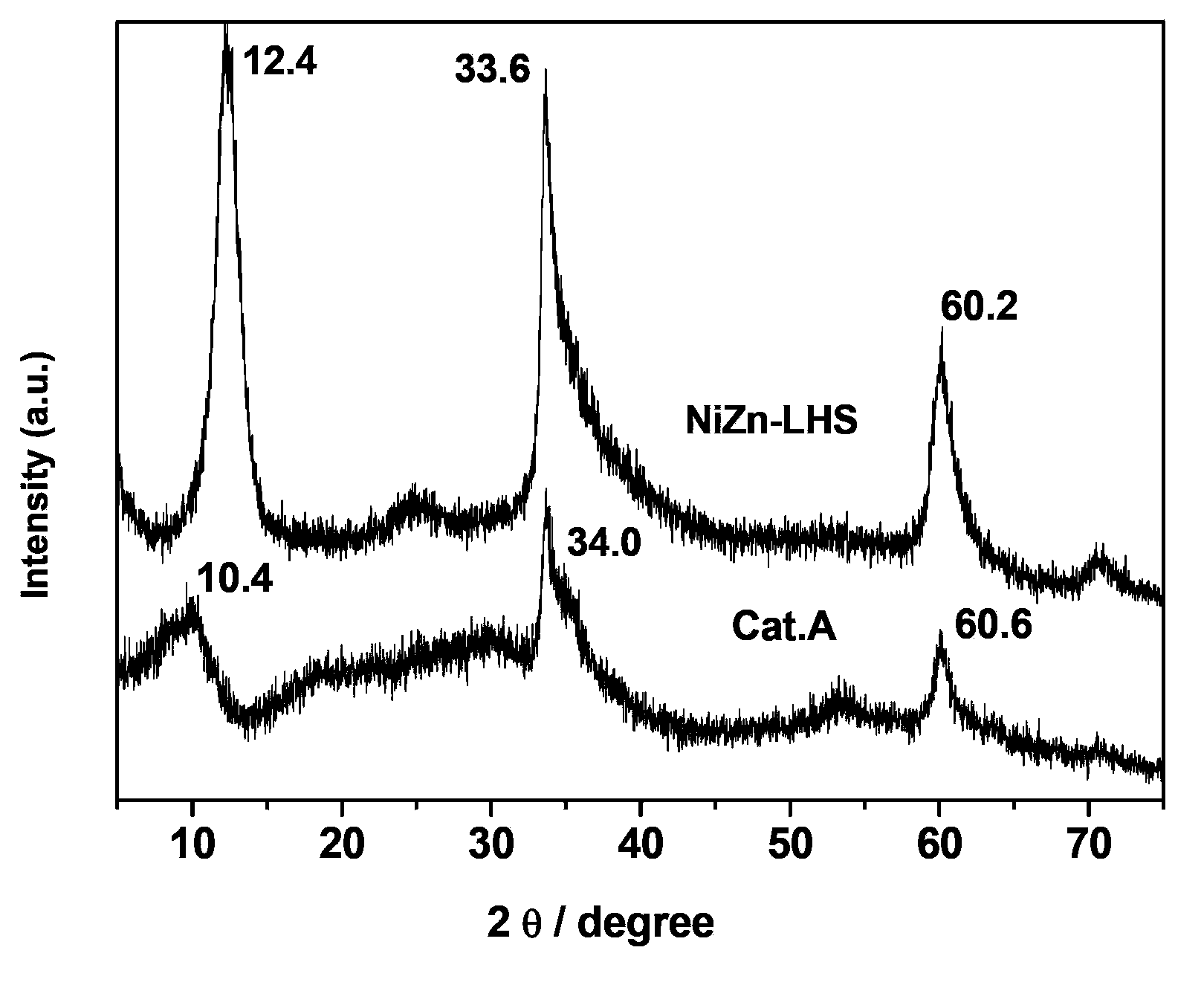

[0071] The present embodiment illustrates the preparation of the NiZnMoW bulk catalyst in the present invention:

[0072] a) Weigh nickel nitrate (29.08g, wherein Ni 2+ 0.1mol) and zinc nitrate (1.49g, where Zn 2+ 0.005mol), they were dissolved in 200ml water to form an aqueous solution, and 0.2mol / L NaOH aqueous solution was slowly added dropwise to it to adjust the pH=12, and heated to the reaction temperature to form a light green mixed reaction solution, which was heated at a reaction temperature of 80°C Reflux reaction 25 hours, obtain light green product; The light green product that reaction obtains is filtered and washed, obtains catalyst precursor (being the NiZn-LHS catalyst precursor with layered structure); This catalyst precursor is added in 200ml water, configured as a slurry precursor (a);

[0073] b) Weigh ammonium molybdate (5.4g, wherein Mo 6+ 0.03mol) and ammonium metatungstate (7.2g, where W 6+ 0.03mol), they are dissolved in water (30ml) to form a solu...

Embodiment 2

[0076] The present embodiment illustrates the preparation of the NiZnMoW bulk catalyst in the present invention:

[0077] Use nickel nitrate (29.08g, where Ni 2+ 0.1mol) and zinc nitrate (2.91g, where Zn 2+ 0.01mol) to replace nickel nitrate (29.08g) used in embodiment 1, wherein Ni 2+ 0.1mol) and zinc nitrate (1.49g, where Zn 2+ 0.005mol), prepare multi-metal bulk catalyst (16.4g) in the same manner as described in Example 1, the multi-metal bulk catalyst of synthesis is represented by Cat-B, and the material morphology of this Cat-B catalyst and Cat -A catalyst is similar. The specific surface area of the catalyst determined by low-temperature nitrogen adsorption is 142m 2 / g, the pore volume is 0.42ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com