G-C3N4 quantum dot modified titanium oxide nanotube catalyst as well as preparation method and application thereof

A titanium oxide nanotube, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to produce hydrogen, low quantum efficiency, etc. The method is simple and efficient, and the effect of photoelectric catalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

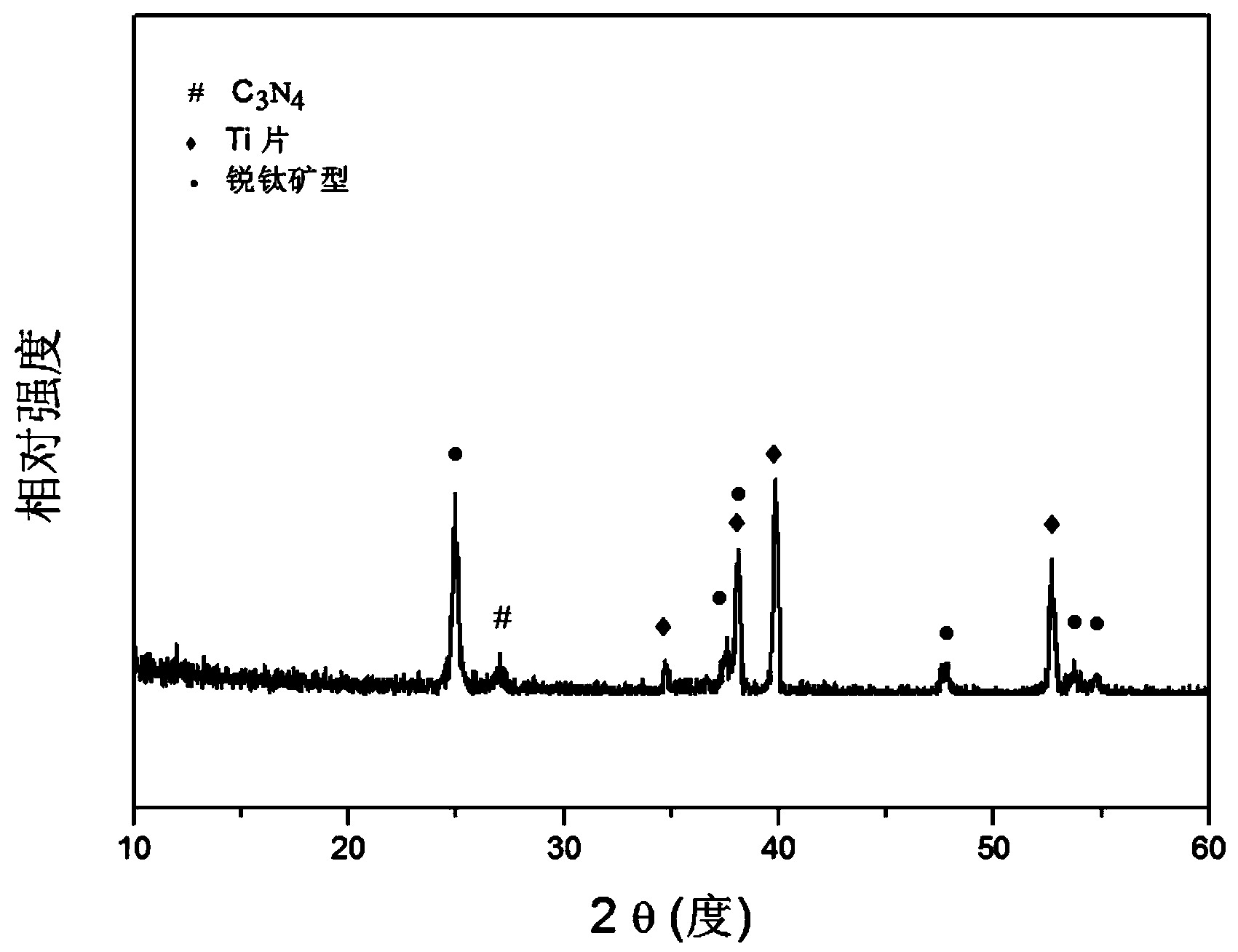

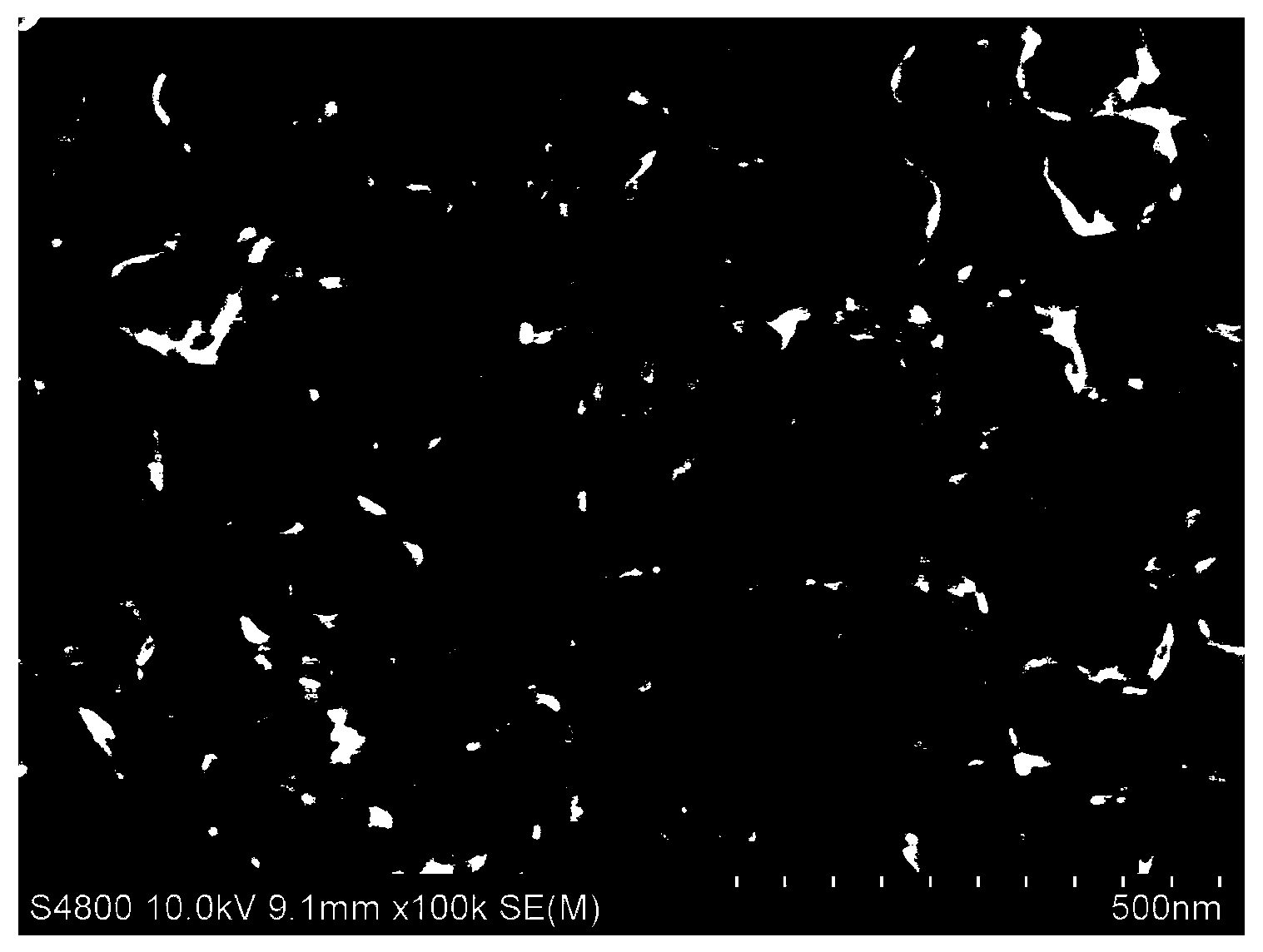

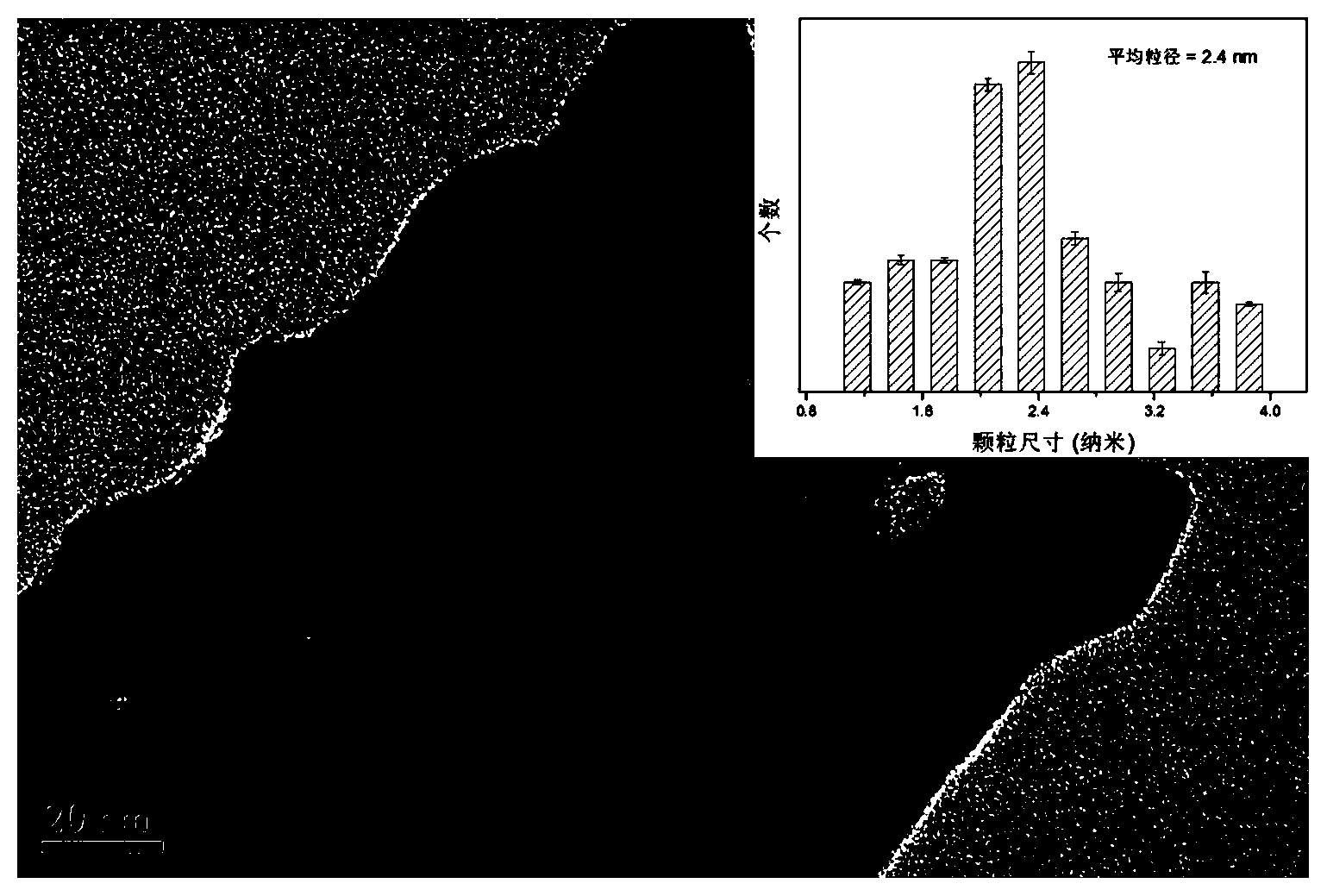

[0019] Add 1g of urea to the crucible with a cover, place a titanium oxide nanotube 3cm away from the precursor to embed it in the crucible, and finally cover it, put it in a muffle furnace for calcination at 550°C for 4 hours, and raise the temperature The rate is 5°C, and finally washed in 0.1M nitric acid solution to obtain g-C 3 N 4 Quantum dot-modified titanium oxide nanotube photocatalyst. Titanium oxide nanotubes prepared by anodic oxidation with a titanium sheet as the substrate have a size of 20mm*33mm*0.3mm.

Embodiment 2

[0021] Add 3g of urea to a crucible with a lid, put titanium oxide nanotubes 2.5cm away from the precursor to embed them in the crucible, and finally cover it, put it in a muffle furnace for calcination at 550°C for 4 hours, and raise the temperature The rate is 5°C, and finally washed in 0.1M nitric acid solution to obtain g-C 3 N 4 Quantum dot-modified titanium oxide nanotube photocatalyst.

Embodiment 3

[0023] Add 5g of urea to a crucible with a lid, place titanium oxide nanotubes 2cm away from the precursor to embed them in the crucible, and finally cover them and put them in a muffle furnace for calcination at 550°C for 4 hours. at 5°C, and finally washed in 0.1M nitric acid solution to obtain g-C 3 N 4 Quantum dot-modified titanium oxide nanotube photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com