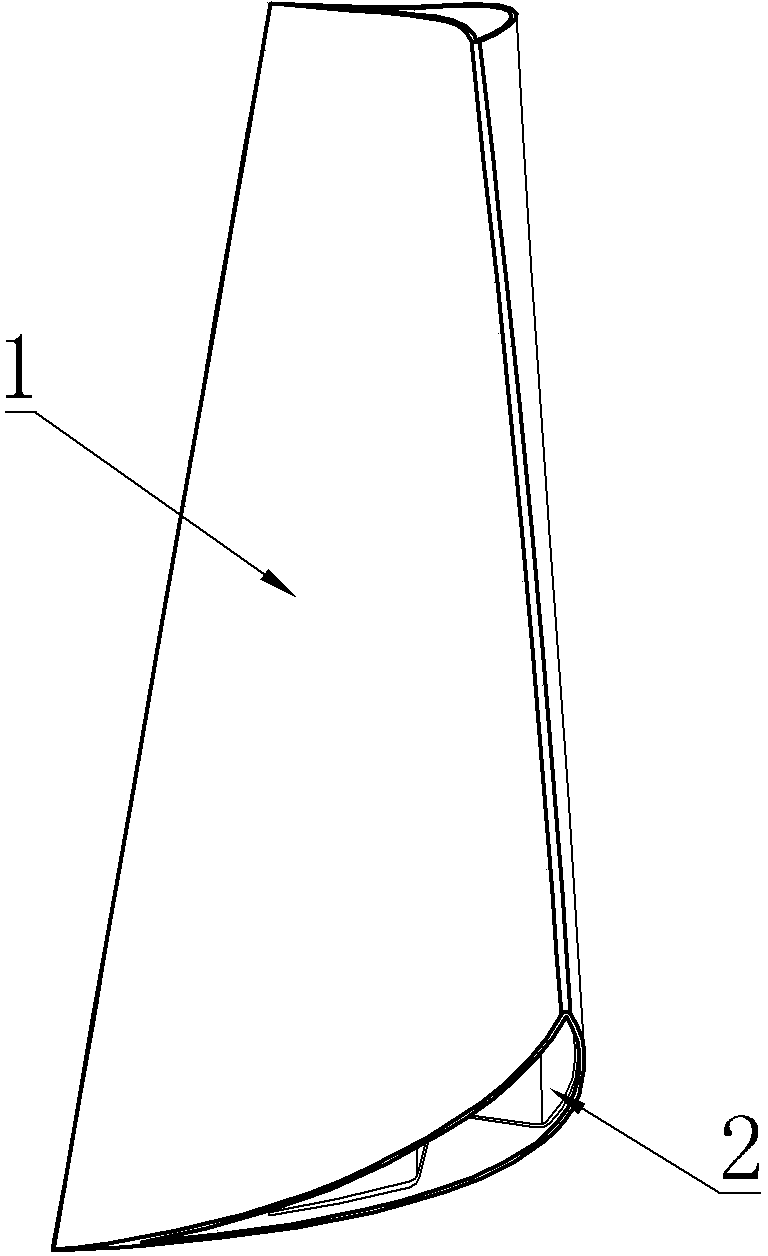

Method for welding hollow static blade body and inner cavity supporting board of turbine

A hollow vane and welding method technology, applied in turbines, welding equipment, mechanical equipment, etc., can solve the problem of inability to reliably weld the hollow vane body and the folded shape support plate, and achieve the purpose of avoiding welding defects and improving comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Firstly, conduct bottom welding on the tapered plug welding hole d, using pure argon gas with a purity of ≥99.99% as the shielding gas, the flow rate of the argon gas is 12L / min, the welding current is 90 A, the welding voltage is 13V, and the wire feeding speed is 13mm / min , 308LSi (ISO 14343-B) welding wire with a diameter of Φ1.0 is used for bottom filling, and less welding wire is sent when making bottom, and the root is penetrated;

[0037] Then plug welding the conical plug welding hole after backing welding until the conical plug welding hole is filled. During plug welding, 308LSi (ISO 14343-B) welding wire with a diameter of Φ2.0 is used for plug welding. The welding current is 110A, the welding voltage is 12 V, pure argon with a purity of ≥99.99% is used as the shielding gas, and the argon flow rate is 12L / min;

[0038] When repairing the defective part, use an argon arc welding torch to repair the defective part, repair welding current: 140A, repair welding vo...

Embodiment 2

[0040] Firstly, conduct bottom welding on the tapered plug welding hole d, using pure argon gas with a purity of ≥99.99% as the shielding gas, the flow rate of the argon gas is 12L / min, the welding current is 100A, the welding voltage is 12 V, and the wire feeding speed is 20mm / min , 308LSi (ISO 14343-B) welding wire with a diameter of Φ1.2 is used for bottom filling, and less welding wire is sent during bottoming, and the root is penetrated;

[0041] Then plug welding the conical plug welding hole after backing welding until the conical plug welding hole is filled. During plug welding, 308LSi (ISO 14343-B) welding wire with a diameter of Φ2.0 is used for plug welding. The welding current is 120A, the welding voltage is 13V, and the pure argon gas with a purity of ≥99.99% is used as the shielding gas, and the flow rate of the argon gas is 12L / min;

[0042]When repairing the defective part, use an argon arc welding torch to repair the defective part, repair welding current: 130...

Embodiment 3

[0044] Firstly, conduct bottom welding on the tapered plug welding hole d, using pure argon gas with a purity of ≥99.99% as the shielding gas, the flow rate of the argon gas is 12L / min, the welding current is 95A, the welding voltage is 14V, and the wire feeding speed is 5 mm / min , 308LSi (ISO 14343-B) welding wire with a diameter of Φ1.0 is used for bottom filling, and less welding wire is sent when making bottom, and the root is penetrated;

[0045] Then plug welding the conical plug welding hole after backing welding until the conical plug welding hole is filled. During plug welding, 308LSi (ISO 14343-B) welding wire with a diameter of Φ2.0 is used for plug welding. The welding current is 100 A ~ 120A, the welding voltage is 12 V ~ 14V, and the pure argon gas with a purity of ≥99.99% is used as the shielding gas, and the flow rate of the argon gas is 12L / min;

[0046] When repairing the defective part, use an argon arc welding torch to repair the defective part, repair weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com