Fabrication of graphene quantum dots by magnetron sputtering

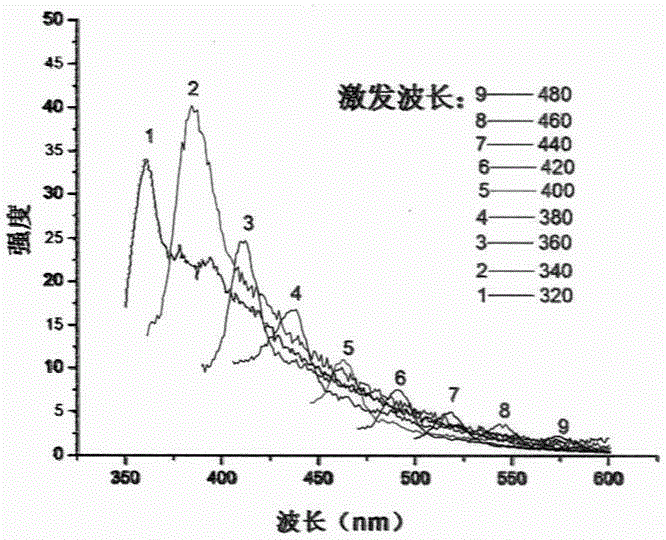

A technology of graphene quantum dots and radio frequency magnetron sputtering, which is applied in the direction of graphene, luminescent materials, chemical instruments and methods, etc., can solve the problems of graphene quantum dots and fluorescence difference that have not been seen yet, and achieve the quantum confinement effect Visible, simple operation, good size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of graphene quantum dot comprises the following steps:

[0030] (1) Set the mass as m c = 0.24g of graphite powder and a mass of m o =79.76g of ZnO powder mixed ball mill (graphite 2mol%), after the ball milling is completed, add 3ml polyvinyl alcohol (PVA) to the mixed powder as a viscous agent and stir well; hold the pressure for 4 minutes under the pressure of 40MPa to put the target Compression molding; target sintering temperature parameters: increase the temperature by 1.5°C per minute, heat it up to 1100°C and keep it for 4 hours.

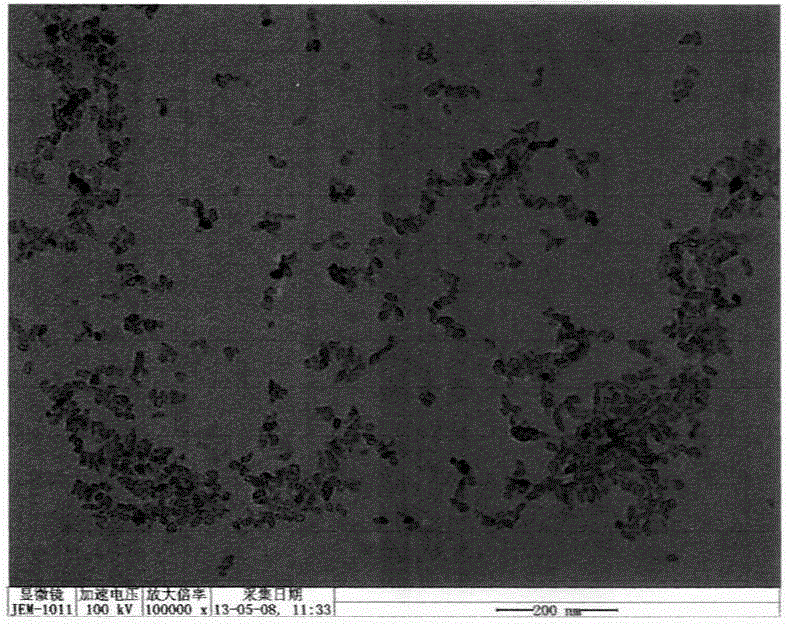

[0031] (2) Put the glass substrate into the magnetron sputtering chamber after cleaning, the distance between the ceramic target and the glass substrate is 60mm, and the background pressure is 1×10 -4 mTorr, high-purity argon gas was introduced as the sputtering gas, the working pressure was 0.5mTorr, the sputtering power was 40W, and the growth time was 15 minutes.

[0032] Put the film s...

Embodiment 2

[0033] Embodiment 2: similar to embodiment 1, its difference is that ZnO powder is changed into Ga 2 o 3 .

Embodiment 3

[0034]Embodiment 3: similar to embodiment 1, its difference is that ZnO powder is changed into Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com