Standardized continuous treatment method of ceramic raw material and production line thereof

A technology for ceramic raw materials and production lines, which is applied in the field of standardized continuous processing methods for ceramic raw materials and its production lines, can solve the problem of not having too many ingredients, and achieve the effects of stable composition, saving production costs, and improving whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

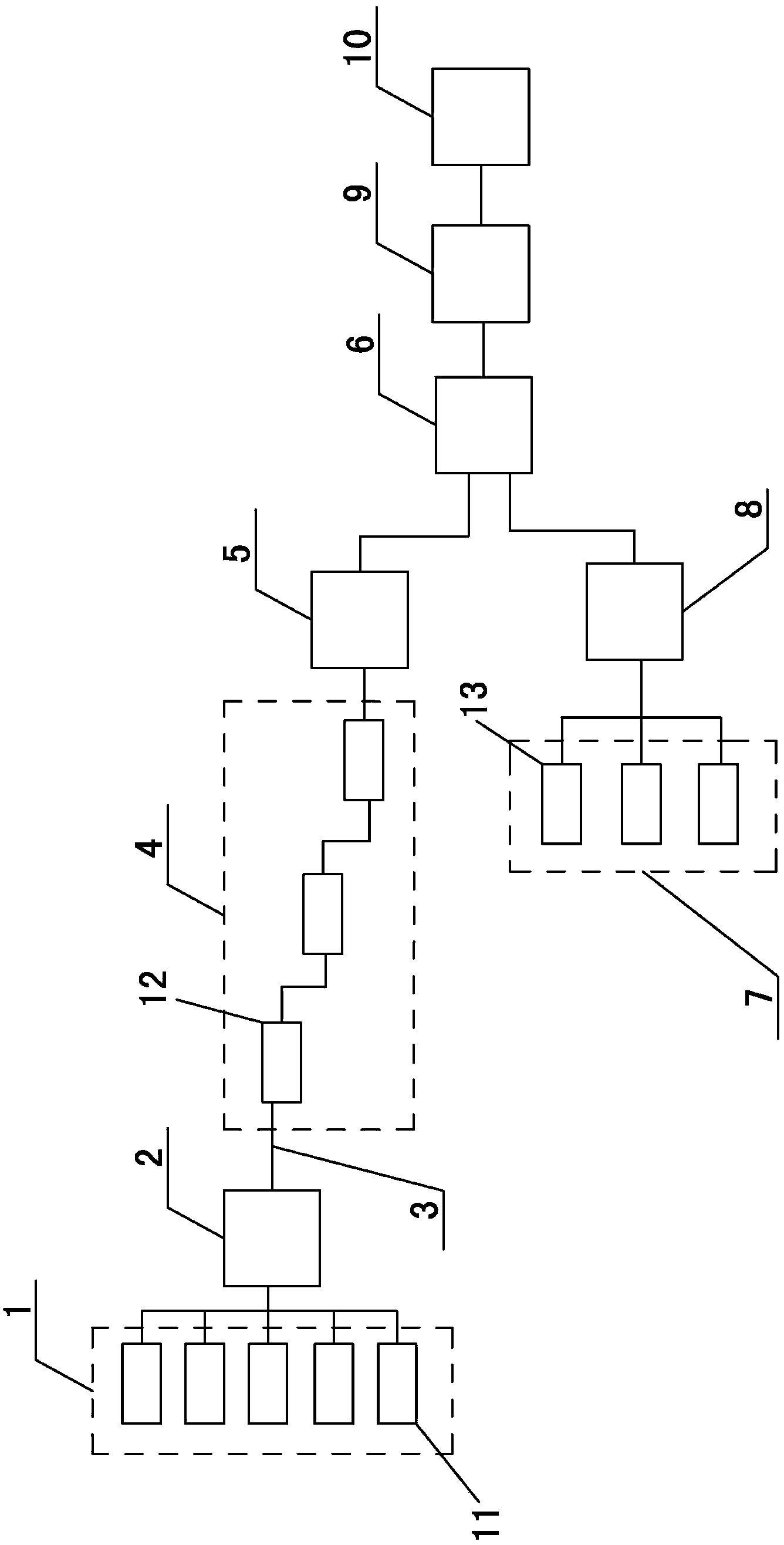

[0015] see figure 1 As shown, a standardized continuous processing production line for ceramic raw materials, which includes a sandstone feeding unit 1, a vertical mill roughing equipment 2, a continuous ball mill unit 4, a slurry equipment 8, a slurry tank for removing iron 5, a ball mill 9 and a spray drying Tower 10; wherein, a number of gravel feeders 11 are arranged in parallel to form a gravel feeder unit 1, which can be equipped with frequency conversion equipment to quantitatively control the output, and the gravel feeder unit 1 is connected to a vertical mill The feed port of the rough processing equipment 2, the discharge port of the vertical mill rough processing device 2 is connected with the feed port of the continuous ball mill unit 4 through the conveyor belt 3, and the continuous ball mill unit 4 is formed by connecting several ball mills 12; The discharge port of the continuous ball mill unit 4 is connected to the feed port of the iron removal slurry tank 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com